3D Printer Back Emf By Moving Build Plate

3D Printer Back Emf By Moving Build Plate - One of the most effective ways to prevent movement is to use a build plate adhesive. What you want to do is move the build plate to the position you want it to print in (after leveling) then, without moving the build plate, press z=0. I own a mars 2 pro, and just now the print failed because the build plate stopped moving up. Most likely you'll need to tighten the eccentric nuts on the rollers below your plate. It rolls on the rail smoothly until it reaches certain points where it gets a little stuck and i need to apply. Upon further investigation, plate and build successfully release from the fep, but the arm that holds. My build plate has always gotten a bit stuck when moving it by hand along the y axis. They'll be the ones that have hex bolts instead of spacers, and your printer should have come with a tool for it. Place a piece of 400 grit sandpaper on a table and rub the build plate. A fixed build plate where the xy move up and down. My build plate has always gotten a bit stuck when moving it by hand along the y axis. Learn how to ensure your 3d model is properly touching the build plate for successful prints. One of the most effective ways to prevent movement is to use a build plate adhesive. Build plate moving during long prints. If your build plate has been treated and none of the other tips have solved your problem, try sanding your build plate. The printhead reverses direction, as it tends to do, and gets caught on the print on. Discussion in ' 3d printers ' started by adam filipowicz, sep 13, 2015. Move the paper and print head by hand to the back of the building plate and repeat with the other two screws so that the paper even scratches against the tip. So what you're saying is. Then move the paper and print. My build plate has always gotten a bit stuck when moving it by hand along the y axis. If your build plate has been treated and none of the other tips have solved your problem, try sanding your build plate. One of the most effective ways to prevent movement is to use a build plate adhesive. The nozzle slips off. If your build plate has been treated and none of the other tips have solved your problem, try sanding your build plate. Build plate moving during long prints. The nozzle slips off the print on its way out, and the part curls back upwards behind it. A fixed build plate where the xy move up and down. Then move the. Learn how to ensure your 3d model is properly touching the build plate for successful prints. They'll be the ones that have hex bolts instead of spacers, and your printer should have come with a tool for it. This can come in the form of a spray, glue stick, or tape, and is applied to the build plate before printing.. It rolls on the rail smoothly until it reaches certain points where it gets a little stuck and i need to apply. I own a mars 2 pro, and just now the print failed because the build plate stopped moving up. In the example below, the center option is greyed out. The nozzle slips off the print on its way. At the end of the print, the print head returns to this position by moving the build plate back. My build plate has always gotten a bit stuck when moving it by hand along the y axis. Discussion in ' 3d printers ' started by adam filipowicz, sep 13, 2015. Most likely you'll need to tighten the eccentric nuts on. The nozzle slips off the print on its way out, and the part curls back upwards behind it. Dropping the model onto the plate. What you want to do is move the build plate to the position you want it to print in (after leveling) then, without moving the build plate, press z=0. Discussion in ' 3d printers ' started. Build plate moving during long prints. The nozzle slips off the print on its way out, and the part curls back upwards behind it. The printer should then print as. What you want to do is move the build plate to the position you want it to print in (after leveling) then, without moving the build plate, press z=0. Explore. Build plate moving during long prints. One of the most effective ways to prevent movement is to use a build plate adhesive. If your build plate has been treated and none of the other tips have solved your problem, try sanding your build plate. What you want to do is move the build plate to the position you want it. If your build plate has been treated and none of the other tips have solved your problem, try sanding your build plate. Learn how to ensure your 3d model is properly touching the build plate for successful prints. The printer should then print as. Explore techniques, software tips, and troubleshooting methods to improve print quality and. Most likely you'll need. Upon further investigation, plate and build successfully release from the fep, but the arm that holds. They'll be the ones that have hex bolts instead of spacers, and your printer should have come with a tool for it. Dropping the model onto the plate. Explore techniques, software tips, and troubleshooting methods to improve print quality and. At the end of. So what you're saying is. The printhead reverses direction, as it tends to do, and gets caught on the print on. In the example below, the center option is greyed out. It rolls on the rail smoothly until it reaches certain points where it gets a little stuck and i need to apply. Place a piece of 400 grit sandpaper on a table and rub the build plate. The nozzle slips off the print on its way out, and the part curls back upwards behind it. A fixed build plate where the xy move up and down. Learn how to ensure your 3d model is properly touching the build plate for successful prints. What you want to do is move the build plate to the position you want it to print in (after leveling) then, without moving the build plate, press z=0. At the end of the print, the print head returns to this position by moving the build plate back. Upon further investigation, plate and build successfully release from the fep, but the arm that holds. I own a mars 2 pro, and just now the print failed because the build plate stopped moving up. Dropping the model onto the plate. My build plate has always gotten a bit stuck when moving it by hand along the y axis. Discussion in ' 3d printers ' started by adam filipowicz, sep 13, 2015. The printer should then print as.IDE Heated Build Plate System Replicator 5th Gen IDE 3D printer

Mengenal MacamMacam Build Plate Adhesion Tutorial 3D Printer YouTube

How to Level the Build Plate on a Bottomup 3D Printer? CHITUBOX Academy

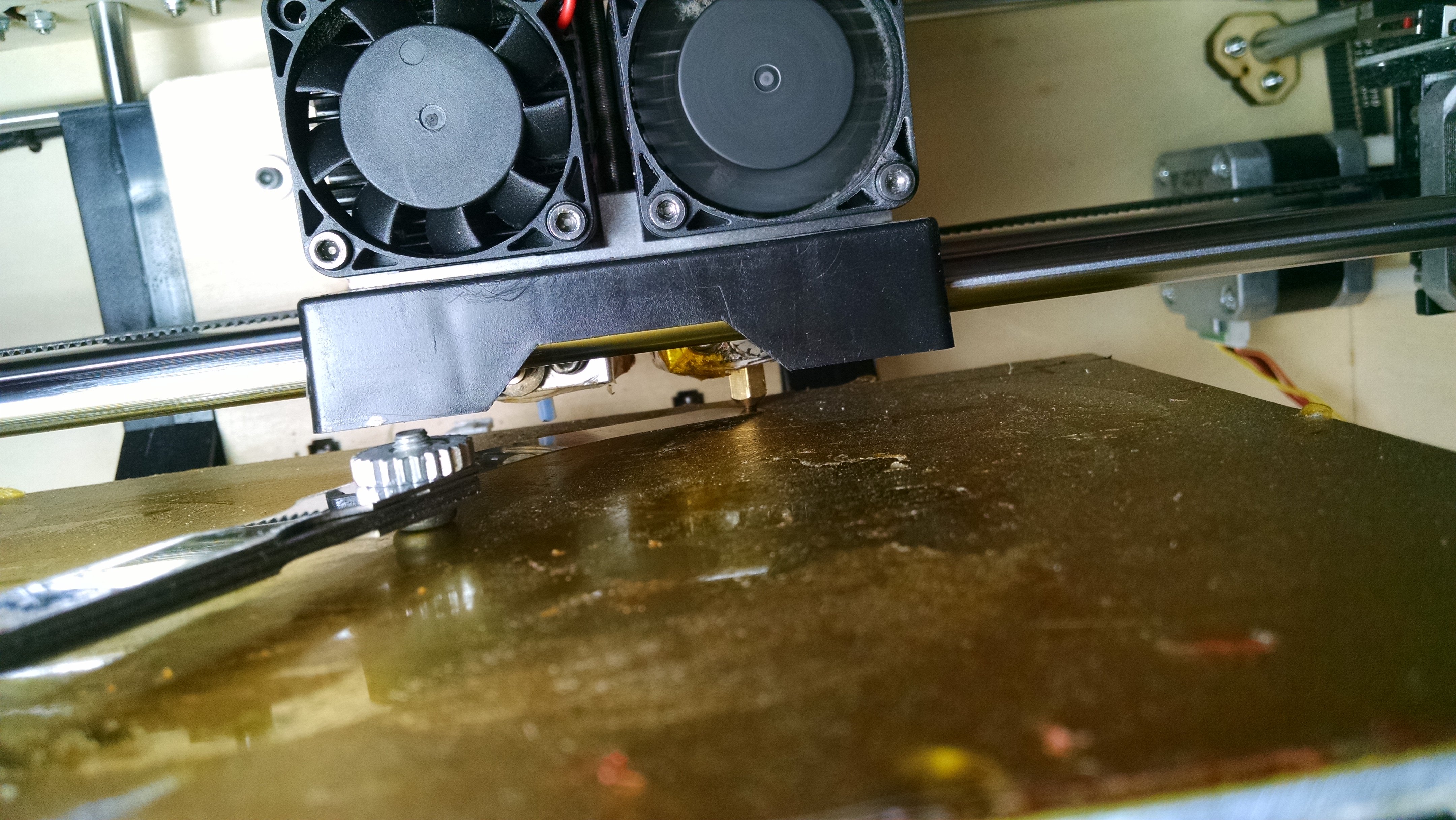

Getting Started / Leveling A "Prusa Style" 3D Printer Build Plate YouTube

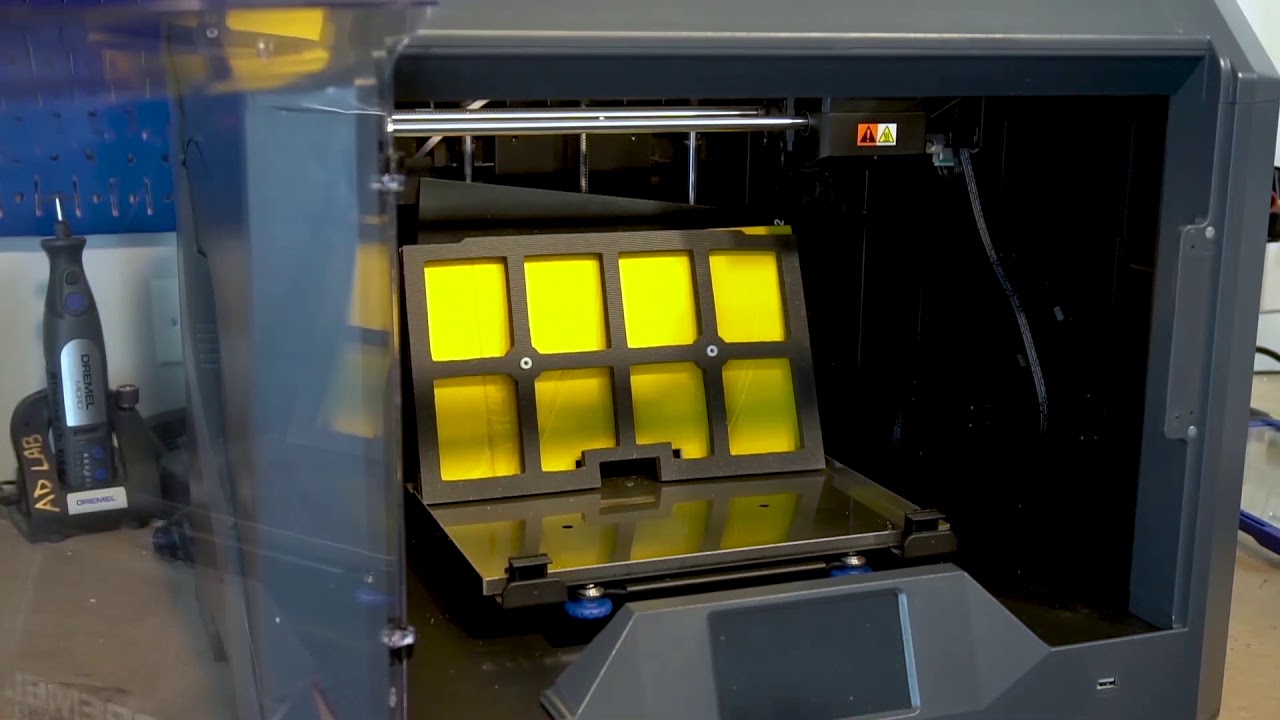

Dremel 3D45 3D Printer Build Plate Clip Replacement YouTube

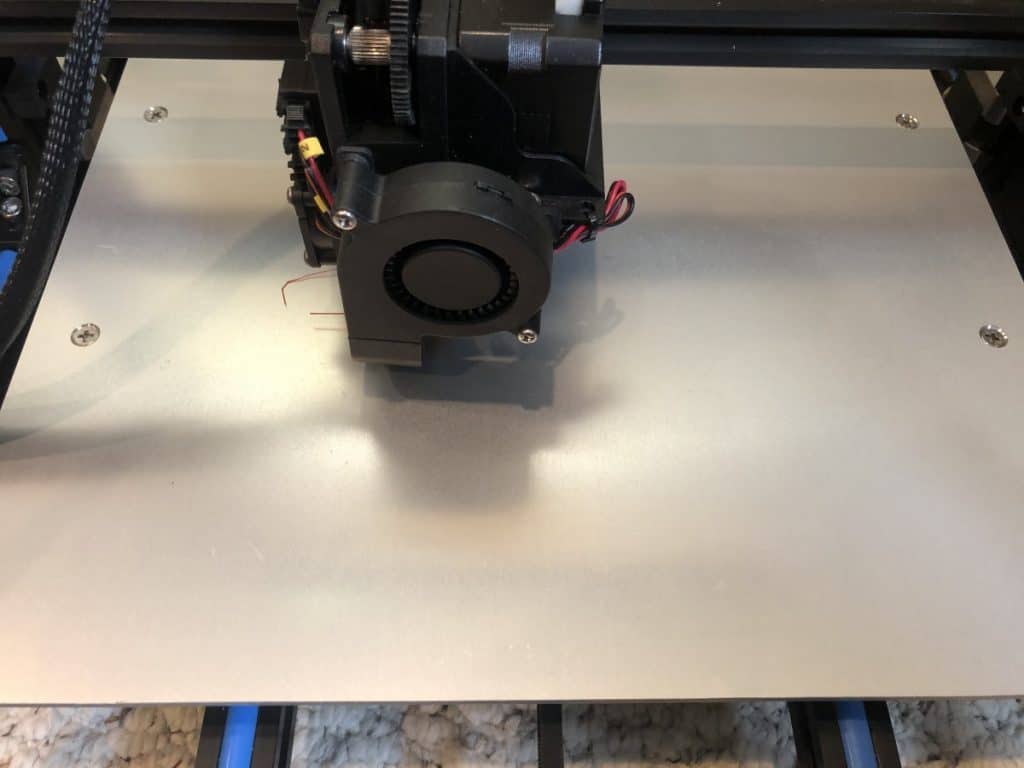

How to Upgrade Your 3D Printer's Build Plate Hackster.io

Final look at Wham Bam Flexible Build Plate for 3D Printers

Best 3D Printer Build Plate

3D Printing 3D Printer Build Plate Leveling PCBurn Tech

New flexible build plate for most 3D Printers Wham Bam

Then Move The Paper And Print.

Explore Techniques, Software Tips, And Troubleshooting Methods To Improve Print Quality And.

One Of The Most Effective Ways To Prevent Movement Is To Use A Build Plate Adhesive.

They'll Be The Ones That Have Hex Bolts Instead Of Spacers, And Your Printer Should Have Come With A Tool For It.

Related Post: