Aac Building

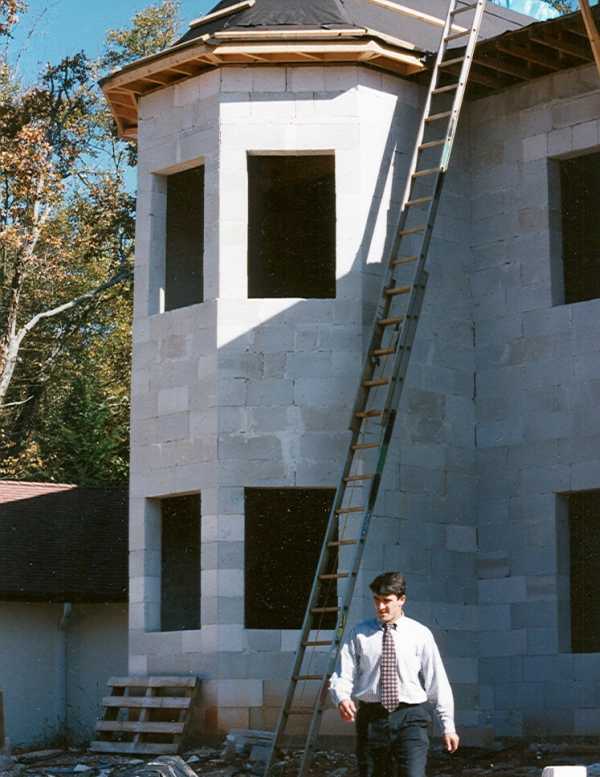

Aac Building - Our guide explains the sizes of aac blocks and how they can be used. This aerated product was first developed in germany. The use of aac blocks reduces a building’s overall dead load by up to 60%, making it possible to construct taller buildings. Aac products are composed from a combination of quartz sand, gypsum, lime, Composed of quartz sand, calcined. But other alternatives may make more sense. Autoclaved aerated concrete (aac) is a lightweight, precast, cellular concrete building material. Aac offers some significant advantages in an age of climate change when we’re needing to build more resilient buildings. Firstly, its composition includes a. This article takes a look at this lightweight building. Aac offers some significant advantages in an age of climate change when we’re needing to build more resilient buildings. Autoclaved aerated concrete looks like an attractive option for an atlanta couple mulling plans for their new house. Autoclaved aerated concrete (aac) is a lightweight, precast, cellular concrete building material. Composed of quartz sand, calcined. The use of aac blocks reduces a building’s overall dead load by up to 60%, making it possible to construct taller buildings. Our guide explains the sizes of aac blocks and how they can be used. Aac is manufactured in plants that are solely designed for their precise production with the flexibility to create masonry and reinforced structural and non structural building. But other alternatives may make more sense. Autoclaved aerated concrete (aac) is a lightweight, precast concrete building material suitable for producing concrete masonry units (cmu) like blocks. Firstly, its composition includes a. Aac is manufactured in plants that are solely designed for their precise production with the flexibility to create masonry and reinforced structural and non structural building. This aerated product was first developed in germany. But other alternatives may make more sense. Autoclaved aerated concrete (aac) is a lightweight, precast concrete building material suitable for producing concrete masonry units (cmu) like. But other alternatives may make more sense. Our guide explains the sizes of aac blocks and how they can be used. Aac products are composed from a combination of quartz sand, gypsum, lime, Autoclaved aerated concrete (aac) is a lightweight, precast, cellular concrete building material. This aerated product was first developed in germany. Autoclaved aerated concrete (aac) is a lightweight, precast, cellular concrete building material. This aerated product was first developed in germany. But other alternatives may make more sense. The use of aac blocks reduces a building’s overall dead load by up to 60%, making it possible to construct taller buildings. Autoclaved aerated concrete looks like an attractive option for an atlanta. The use of aac blocks reduces a building’s overall dead load by up to 60%, making it possible to construct taller buildings. Our guide explains the sizes of aac blocks and how they can be used. Autoclaved aerated concrete looks like an attractive option for an atlanta couple mulling plans for their new house. This article takes a look at. Aac offers some significant advantages in an age of climate change when we’re needing to build more resilient buildings. Autoclaved aerated concrete (aac) is a lightweight, precast, cellular concrete building material. But other alternatives may make more sense. Aac is manufactured in plants that are solely designed for their precise production with the flexibility to create masonry and reinforced structural. Find the right size aac block for your construction job. Aac is manufactured in plants that are solely designed for their precise production with the flexibility to create masonry and reinforced structural and non structural building. But other alternatives may make more sense. Firstly, its composition includes a. Autoclaved aerated concrete looks like an attractive option for an atlanta couple. This article takes a look at this lightweight building. This aerated product was first developed in germany. Find the right size aac block for your construction job. Aac products are composed from a combination of quartz sand, gypsum, lime, Firstly, its composition includes a. Composed of quartz sand, calcined. Firstly, its composition includes a. This aerated product was first developed in germany in the 1880s, then. Aac products are composed from a combination of quartz sand, gypsum, lime, Autoclaved aerated concrete looks like an attractive option for an atlanta couple mulling plans for their new house. The use of aac blocks reduces a building’s overall dead load by up to 60%, making it possible to construct taller buildings. Find the right size aac block for your construction job. Composed of quartz sand, calcined. But other alternatives may make more sense. Aac is manufactured in plants that are solely designed for their precise production with the flexibility. This aerated product was first developed in germany in the 1880s, then. Autoclaved aerated concrete (aac) is a lightweight, precast concrete building material suitable for producing concrete masonry units (cmu) like blocks. Our guide explains the sizes of aac blocks and how they can be used. This article takes a look at this lightweight building. Aac offers some significant advantages. Aac is manufactured in plants that are solely designed for their precise production with the flexibility to create masonry and reinforced structural and non structural building. This aerated product was first developed in germany. Our guide explains the sizes of aac blocks and how they can be used. This article takes a look at this lightweight building. Aac products are composed from a combination of quartz sand, gypsum, lime, Autoclaved aerated concrete (aac) is a lightweight, precast, cellular concrete building material. Autoclaved aerated concrete (aac) is a lightweight, precast concrete building material suitable for producing concrete masonry units (cmu) like blocks. Aac offers some significant advantages in an age of climate change when we’re needing to build more resilient buildings. Autoclaved aerated concrete looks like an attractive option for an atlanta couple mulling plans for their new house. But other alternatives may make more sense. Firstly, its composition includes a. This aerated product was first developed in germany in the 1880s, then.The Aircrete Building System and its AAC components Aircrete Europe

Autoclaved Aerated Concrete AAC Building Wall Stock Image Image of

Autoclaved Aerated Concrete Blocks (AAC Blocks) Engineering Discoveries

Autoclaved Aerated Concrete Archives AAC Blocks Building Construction

Aac Block Construction Details Archives AAC Blocks Building

Autoclaved Aerated Concrete (AAC) Will the U.S. Ever Lighten Up

Which is Best for Commercial Building AAC Blocks / Red Bricks

AAC blocks and rapid building techniques Future of construction

Building with conecc aac blocks Artofit

How AAC Blocks Are Made And Their Advantages

The Use Of Aac Blocks Reduces A Building’s Overall Dead Load By Up To 60%, Making It Possible To Construct Taller Buildings.

Find The Right Size Aac Block For Your Construction Job.

Composed Of Quartz Sand, Calcined.

Related Post: