Air Build Up Test

Air Build Up Test - In a vehicle with a single air brake system, after the engine is at operating rpms, the pressure in the air system should generally build from 50 to 90 psi within three minutes. Most trucks build sufficient air in. Most trucks build sufficient air in 1/3 of the time allocated for minimum standard. To ensure the air compressor can meet the demand of the air brake system and restore pressure quickly, you must test whether the air pressure rises to a. This test evaluates the working of the air compressor. Check security and condition of compressor, belts and air lines under hood. With wheels blocked, release park brakes. Check rate of air pressure. If the vehicle has a trailer attached, ensure the trailer supply valve is closed (pulled out). A gift to you from your catholic school wednesday 12th february wednesday 19th february wednesday 26th feb ruary sunday’s gospel connecting home, school and parish Start engine and let air pressure build up. In a vehicle with a single air brake system, after the engine is at operating rpms, the pressure in the air system should generally build from 50 to 90 psi within three minutes. With wheels blocked, release park brakes. When travelling on the road, the air pressure drops with the frequent use of brakes. Study with quizlet and memorize flashcards containing terms like air system checks, static test, applied air test and more. Check security and condition of compressor, belts and air lines under hood. To troubleshoot effectively, it's vital to inspect your air brake system for signs of the ten most common causes of air brake issues. If the vehicle has a trailer attached, ensure the trailer supply valve is closed (pulled out). When the engine is at operating rpm, the pressure should build from 85 to 100 psi within 45 seconds in dual air systems (if the vehicle has larger than minimum air tanks, the buildup time. Reduce air pressure to below 552 kpa (80 psi). Check rate of air pressure. Start engine and let air pressure build up. A blower door tests the continuity and integrity of the air barrier, a test of the “air tightness” of a structure. Study with quizlet and memorize flashcards containing terms like air system checks, static test, applied air test and more. The air compressor must be capable of. In a vehicle with a single air brake system, after the engine is at operating rpms, the pressure in the air system should generally build from 50 to 90 psi within three minutes. This test evaluates the working of the air compressor. The compressor on an air brake equipped vehicle is a basic component. To troubleshoot effectively, it's vital to. In a vehicle with a single air brake system, after the engine is at operating rpms, the pressure in the air system should generally build from 50 to 90 psi within three minutes. Reduce air pressure to below 552 kpa (80 psi). Check rate of air pressure. Start engine and let air pressure build up. The compressor on an air. Most trucks build sufficient air in 1/3 of the time allocated for minimum standard. When the engine is at operating rpm, the pressure should build from 85 to 100 psi within 45 seconds in dual air systems (if the vehicle has larger than minimum air tanks, the buildup time. Here is a quick checklist on how to test the air. Start engine and let air pressure build up. You should be on level ground with the wheels chocked for some parts of this checklist. To test air system integrity, make and hold a full brake application for at least 2 minutes while watching the air pressure gauge with the engine off, the key in the “on” position, and the park.. Check rate of air pressure. To troubleshoot effectively, it's vital to inspect your air brake system for signs of the ten most common causes of air brake issues. If the vehicle has a trailer attached, ensure the trailer supply valve is closed (pulled out). This test evaluates the working of the air compressor. Study with quizlet and memorize flashcards containing. You should be on level ground with the wheels chocked for some parts of this checklist. In a vehicle with a single air brake system, after the engine is at operating rpms, the pressure in the air system should generally build from 50 to 90 psi within three minutes. To resolve air brake dysfunction, first diagnose the core. Air pressure. To troubleshoot effectively, it's vital to inspect your air brake system for signs of the ten most common causes of air brake issues. A gift to you from your catholic school wednesday 12th february wednesday 19th february wednesday 26th feb ruary sunday’s gospel connecting home, school and parish If the vehicle has a trailer attached, ensure the trailer supply valve. Check rate of air pressure. Here is a quick checklist on how to test the air and brake systems: Most trucks build sufficient air in. Step on and off the brake pedal to reduce air pressure. Most trucks build sufficient air in 1/3 of the time allocated for minimum standard. Start engine and let air pressure build up. If the vehicle has a trailer attached, ensure the trailer supply valve is closed (pulled out). Most trucks build sufficient air in 1/3 of the time allocated for minimum standard. A gift to you from your catholic school wednesday 12th february wednesday 19th february wednesday 26th feb ruary sunday’s gospel connecting home,. Start engine and let air pressure build up. To ensure the air compressor can meet the demand of the air brake system and restore pressure quickly, you must test whether the air pressure rises to a. When travelling on the road, the air pressure drops with the frequent use of brakes. With wheels blocked, release park brakes. Study with quizlet and memorize flashcards containing terms like air system checks, static test, applied air test and more. If the vehicle has a trailer attached, ensure the trailer supply valve is closed (pulled out). When the engine is at operating rpm, the pressure should build from 85 to 100 psi within 45 seconds in dual air systems (if the vehicle has larger than minimum air tanks, the buildup time. Check rate of air pressure. Most trucks build sufficient air in 1/3 of the time allocated for minimum standard. A gift to you from your catholic school wednesday 12th february wednesday 19th february wednesday 26th feb ruary sunday’s gospel connecting home, school and parish To test air system integrity, make and hold a full brake application for at least 2 minutes while watching the air pressure gauge with the engine off, the key in the “on” position, and the park. Most trucks build sufficient air in. Check security and condition of compressor, belts and air lines under hood. Here is a quick checklist on how to test the air and brake systems: To resolve air brake dysfunction, first diagnose the core. A blower door tests the continuity and integrity of the air barrier, a test of the “air tightness” of a structure.33. Pressure buildup test find permeability YouTube

Effect of API Gravity Change on BuildUP Tests. Download Scientific

Fatigue Heat BuildUp testing module Metravib Material Testing

36. Pressure buildup test finding average pressure of the reservoir

Derivative of pressure buildup test calculation and derivative of

Air Tightness Testing The what, when & how Buildpass BuildPass

Combustion Flue Gas Analyser Kit c/w Tightness & CO Build Up Test inc

Pressure Buildup Test A Step By Step Approach YouTube

The Compressor and Build Up Test CDL Air Brakes Pass CDL License

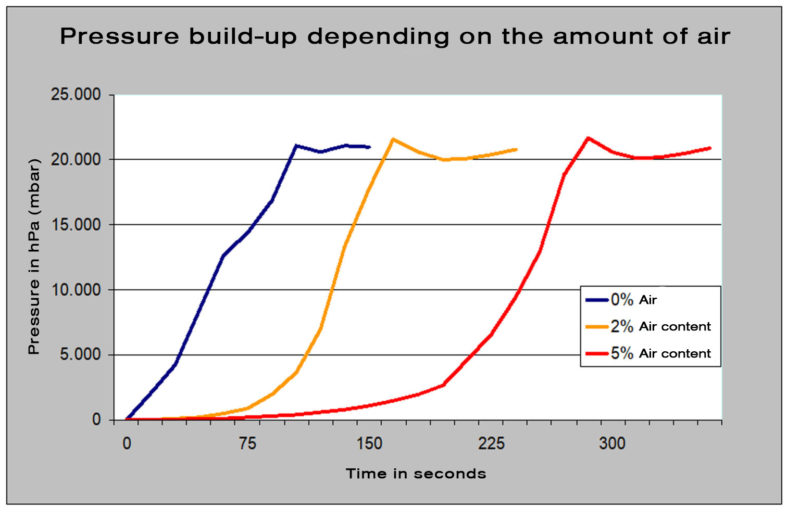

The basics of pressure tests on water pipelines Esders GmbH

Testing Is Performed Using A Fan That Creates A Pressure Difference.

Reduce Air Pressure To Below 552 Kpa (80 Psi).

This Test Evaluates The Working Of The Air Compressor.

To Troubleshoot Effectively, It's Vital To Inspect Your Air Brake System For Signs Of The Ten Most Common Causes Of Air Brake Issues.

Related Post: