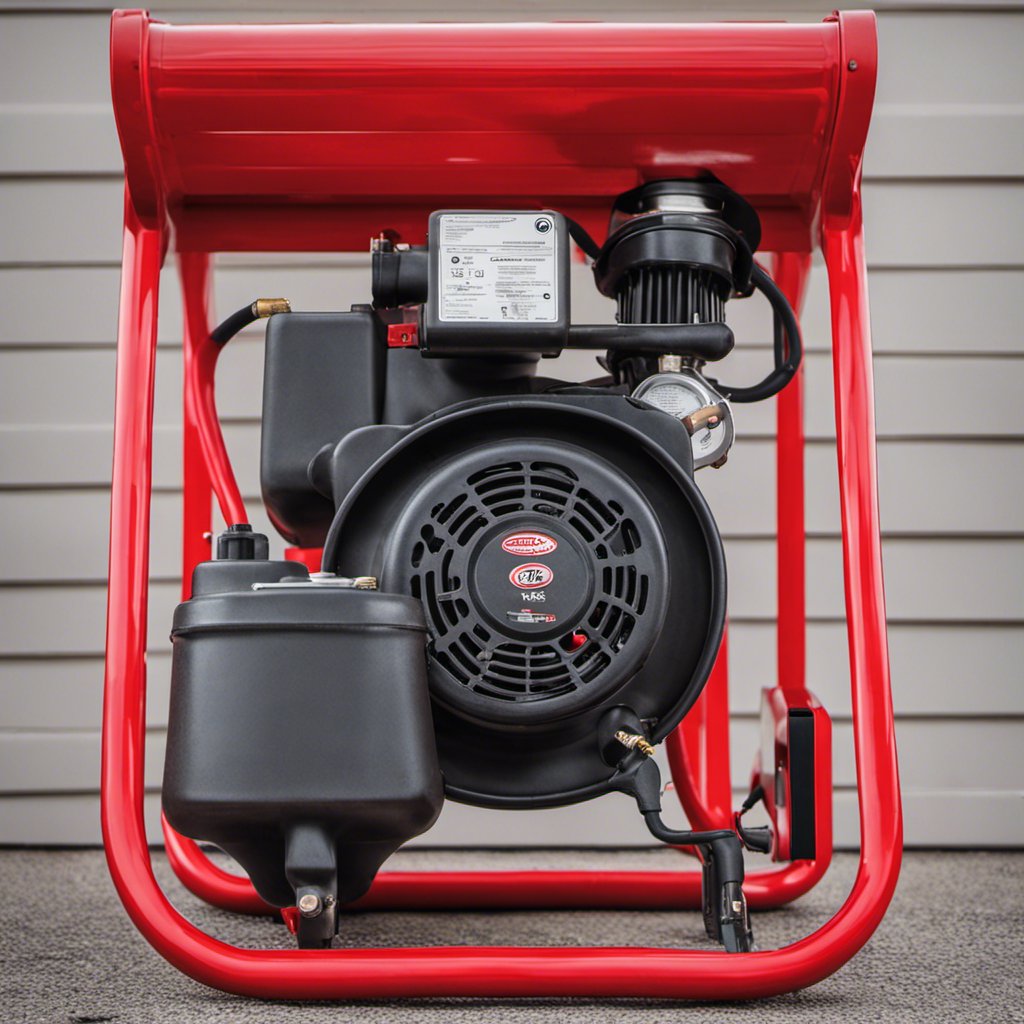

Air Compressor Slow To Build Pressure

Air Compressor Slow To Build Pressure - First of all, inspect the air inlet filters. You would have to check the intake first to make sure that your compressor gets enough air. Easiest way for a shade tree mechanic, hook the output of the compressor to an air tank (portable tire inflation tank) take the governor off. Common causes of pressure loss 1. Your “after a couple of cycles the compressor. If the compressor’s air intake is blocked or restricted, it can’t draw in enough air to maintain pressure. Start truck, is air leaking out the. If your air compressor isn’t building enough pressure to carry out its given function, it can derail your workday. A faulty belt is a common cause of an air compressor failing to build pressure. If any of the valves in the sequence of pistons, or the valves in a single piston air compressor for that matter, seize up or break, the ensuing blockage of air flow could result in a. Follow these steps to troubleshoot and build pressure in your air compressor: Common causes of pressure loss 1. If your air compressor isn’t building enough pressure to carry out its given function, it can derail your workday. If you saw something you didn. This could be due to a clogged air filter or other obstruction. A faulty belt is a common cause of an air compressor failing to build pressure. Typically, the belt has stretched or deformed to the point that it is slipping and no longer able to turn the flywheel. Start truck, is air leaking out the. Check for leaks in the hoses, fittings,. Check the air filter for blockages. To prevent such a situation, it is important to learn a few things that will help you when your compressor will not build enough pressure. Check for leaks in the hoses, fittings,. Common causes of pressure loss 1. Usually, if an air compressor is taking long to the fill it typically is either a seal problem, gasket failure, or an. Follow these steps to troubleshoot and build pressure in your air compressor: Air leaks are one of the most common reasons for pressure loss in an air compressor. This could be due to a clogged air filter or other obstruction. If your air compressor isn’t building enough pressure to carry out its given function, it can derail your workday. If. Typically, the belt has stretched or deformed to the point that it is slipping and no longer able to turn the flywheel. Check the air filter for blockages. This could be due to a clogged air filter or other obstruction. Check for leaks in the hoses, fittings,. Air leaks are one of the most common reasons for pressure loss in. First of all, inspect the air inlet filters. Air leaks are one of the most common reasons for pressure loss in an air compressor. Follow these steps to troubleshoot and build pressure in your air compressor: This could be due to a clogged air filter or other obstruction. Check the air filter for blockages. Usually, if an air compressor is taking long to the fill it typically is either a seal problem, gasket failure, or an intake or pressure valve failing. If your air compressor isn’t building enough pressure to carry out its given function, it can derail your workday. Start truck, is air leaking out the. You would have to check the intake. Your “after a couple of cycles the compressor. First of all, inspect the air inlet filters. Then you can check the exhaust side and see if there is constant good pressure. If your air compressor isn’t building enough pressure to carry out its given function, it can derail your workday. Follow these steps to troubleshoot and build pressure in your. If any of the valves in the sequence of pistons, or the valves in a single piston air compressor for that matter, seize up or break, the ensuing blockage of air flow could result in a. Air leaks are one of the most common reasons for pressure loss in an air compressor. If your air compressor isn’t building enough pressure. If any of the valves in the sequence of pistons, or the valves in a single piston air compressor for that matter, seize up or break, the ensuing blockage of air flow could result in a. Check the air filter for blockages. Air leaks are one of the most common reasons for pressure loss in an air compressor. Start truck,. Common causes of pressure loss 1. Check for leaks in the hoses, fittings,. Usually, if an air compressor is taking long to the fill it typically is either a seal problem, gasket failure, or an intake or pressure valve failing. A faulty belt is a common cause of an air compressor failing to build pressure. Start truck, is air leaking. To prevent such a situation, it is important to learn a few things that will help you when your compressor will not build enough pressure. Check for leaks in the hoses, fittings,. If you saw something you didn. Typically, the belt has stretched or deformed to the point that it is slipping and no longer able to turn the flywheel.. If your air compressor isn’t building enough pressure to carry out its given function, it can derail your workday. Then you can check the exhaust side and see if there is constant good pressure. This could be due to a clogged air filter or other obstruction. Typically, the belt has stretched or deformed to the point that it is slipping and no longer able to turn the flywheel. Air leaks are one of the most common reasons for pressure loss in an air compressor. First of all, inspect the air inlet filters. If any of the valves in the sequence of pistons, or the valves in a single piston air compressor for that matter, seize up or break, the ensuing blockage of air flow could result in a. Common causes of pressure loss 1. Follow these steps to troubleshoot and build pressure in your air compressor: Easiest way for a shade tree mechanic, hook the output of the compressor to an air tank (portable tire inflation tank) take the governor off. If the compressor’s air intake is blocked or restricted, it can’t draw in enough air to maintain pressure. To prevent such a situation, it is important to learn a few things that will help you when your compressor will not build enough pressure. If you saw something you didn. Your “after a couple of cycles the compressor. Check for leaks in the hoses, fittings,. Usually, if an air compressor is taking long to the fill it typically is either a seal problem, gasket failure, or an intake or pressure valve failing.5 Reasons Why Your Air Compressor Is Slow to Build Pressure (And How to

How To Repair Air Compressor Valves!! Air compressor, Compressor, Repair

5 Reasons Why Your Air Compressor Is Slow to Build Pressure (And How to

How To Fix Air Compressor Not Building Pressure. YouTube

5 Reasons Why Your Air Compressor Is Slow to Build Pressure (And How to

How to fix air compressor that doesn't build enough pressure YouTube

Air Compressor Not Building Pressure?!? "Free Fix" YouTube

Husky Air Compressor Won't Build Pressure Why does my air compressor

5 Reasons Why Your Air Compressor Is Slow to Build Pressure (And How to

How to repair fix air compressor not building pressure easy fix YouTube

Check The Air Filter For Blockages.

A Faulty Belt Is A Common Cause Of An Air Compressor Failing To Build Pressure.

You Would Have To Check The Intake First To Make Sure That Your Compressor Gets Enough Air.

Start Truck, Is Air Leaking Out The.

Related Post: