Build 3D Printer

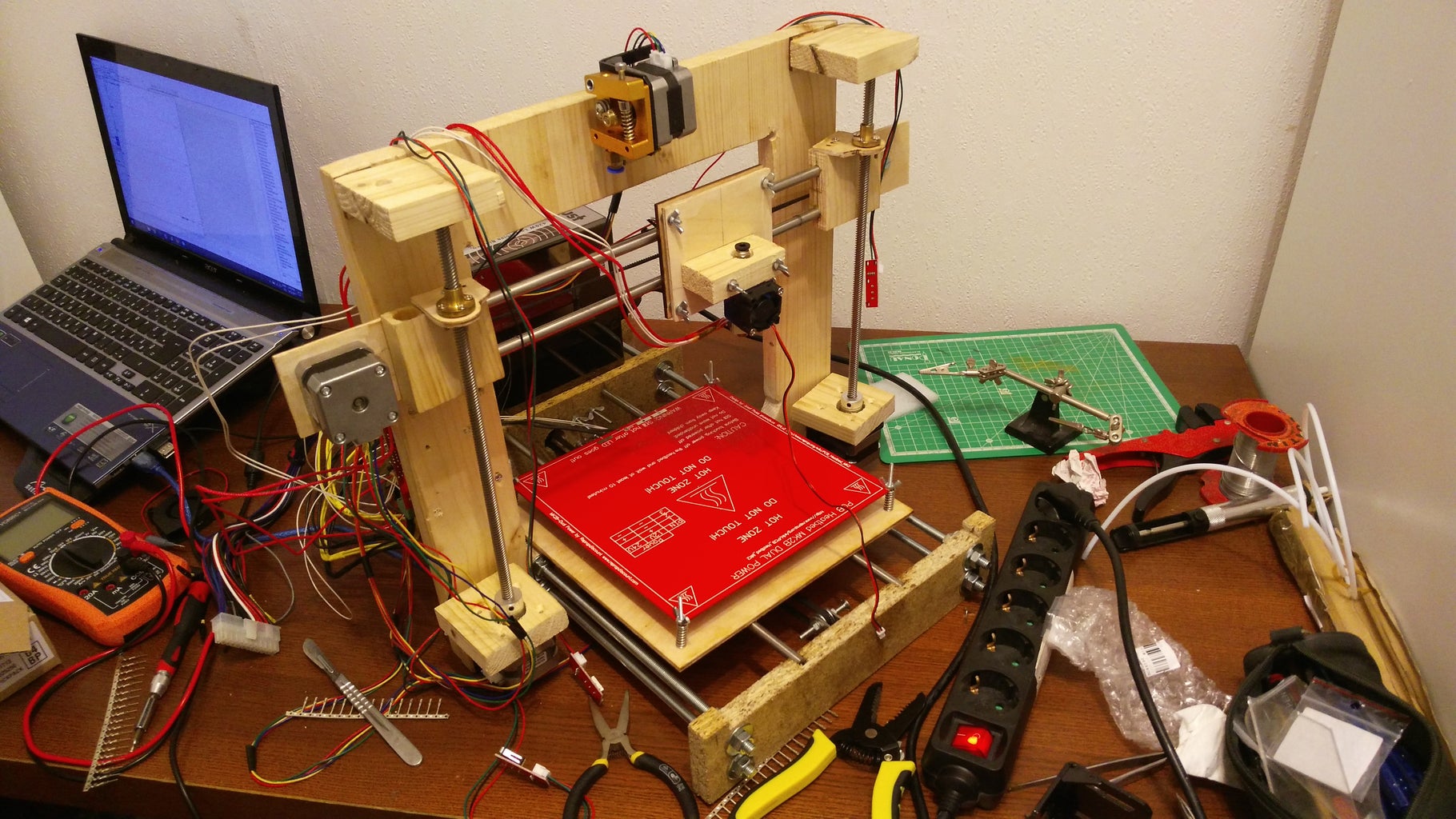

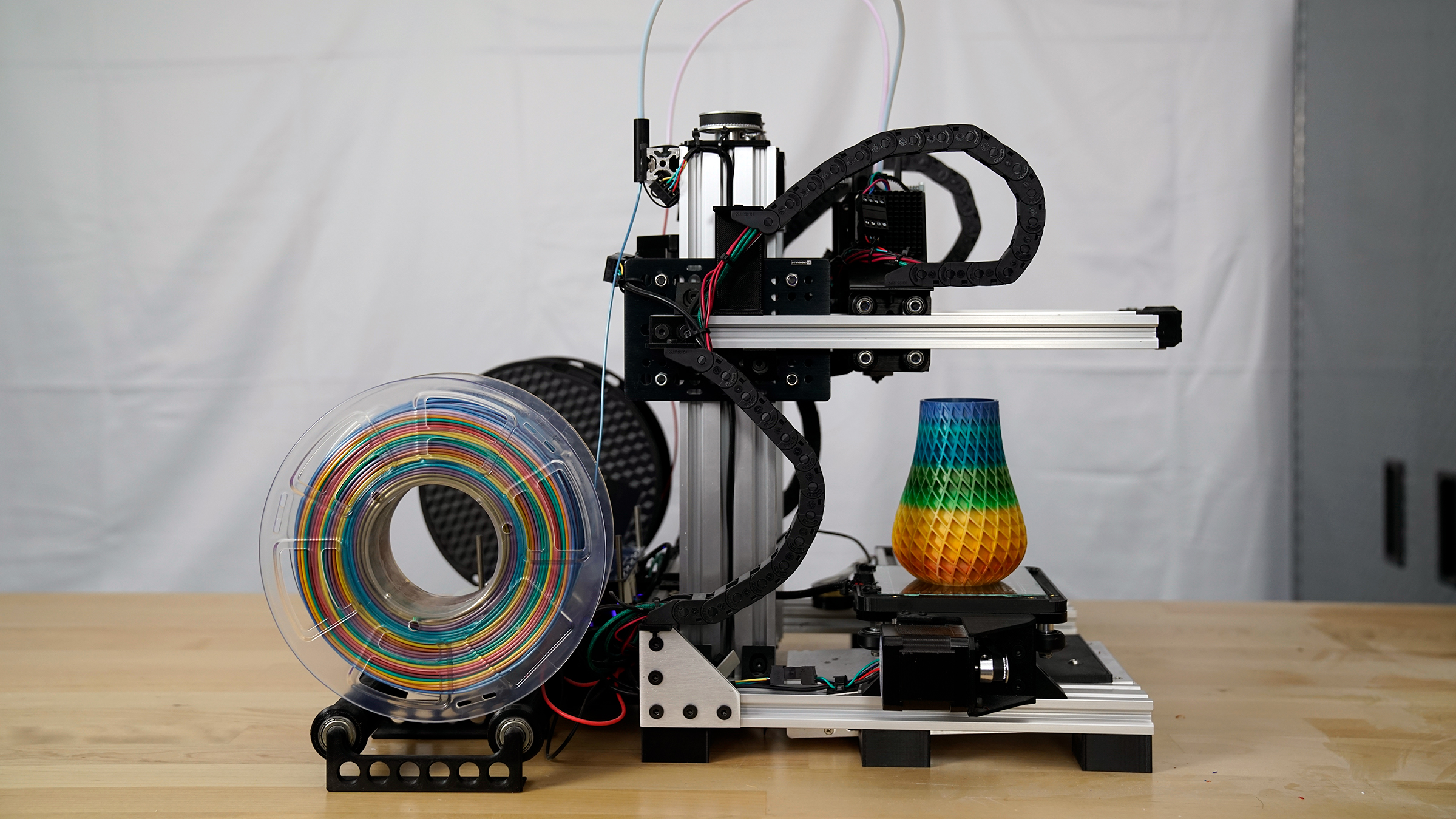

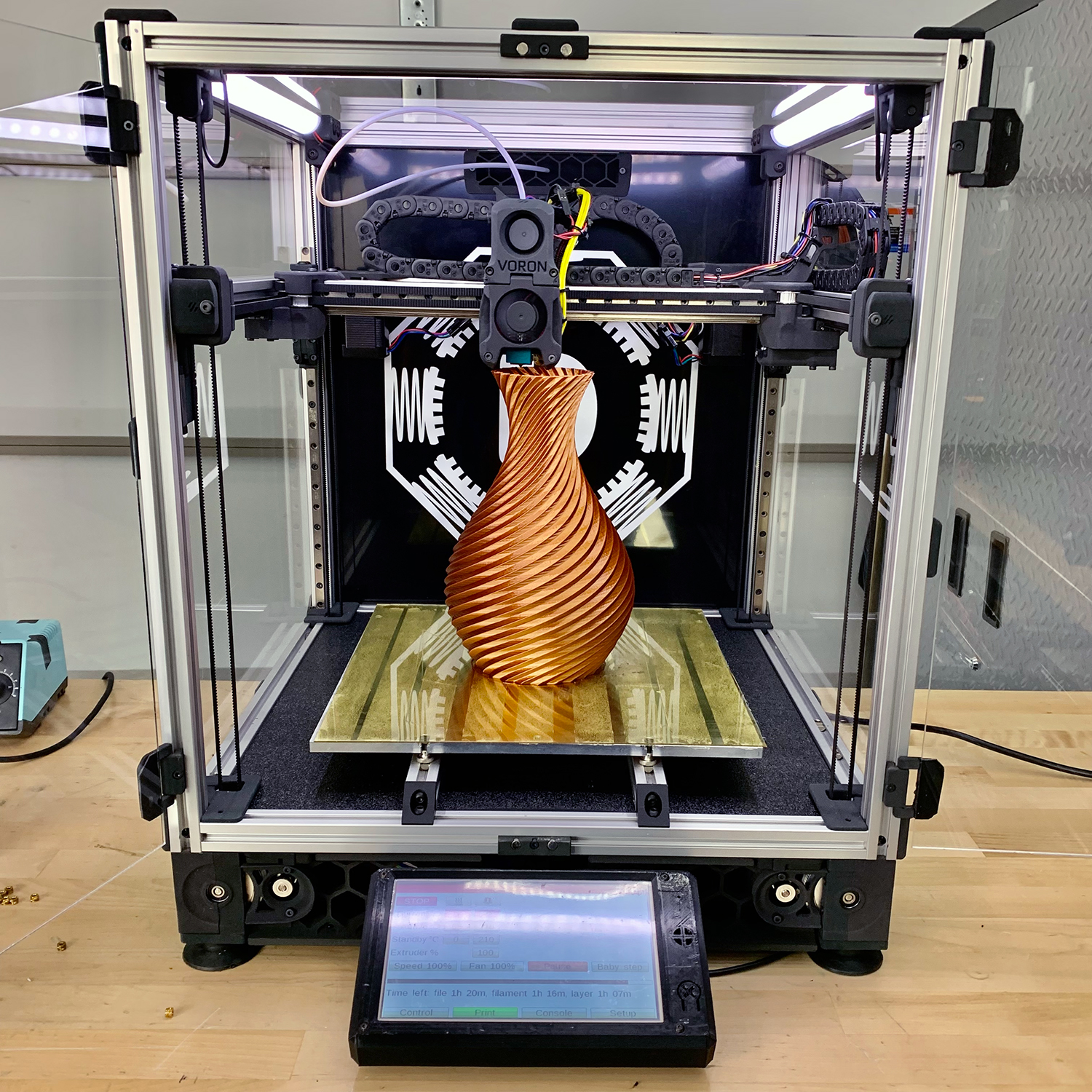

Build 3D Printer - How do you make your own 3d printer? By building your own 3d printer you get to learn about every aspect of the machine and process. So this time i made a 3d printer from some waste/residual wood, some recycled electronic parts and about 120$. There are smaller and larger printers on the market, but this. A 3d concrete printer is being used to build a home in perth's north. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. When building a 3d printer, choosing the right parts is crucial to ensure that the printer functions effectively. Anyone can easily build their very own 3d printer in just one day. In this section, we will discuss the most important parts of a 3d printer and what to. The resulting powder can then be fed into 3d printers. Tyson build plates are available for bambu lab 3d printers, and limited production runs can be made for standard 120 mm, 180 mm, 250 mm and 300 mm plates to support. The first way is to start building the 3d printer all by yourself. While it may seem intimidating at first, it’s actually. By building your own 3d printer you get to learn about every aspect of the machine and process. Rating 3.6 out of 5 stars with 9 reviews (9) $1,499.99 your price for this item is $1,499.99. Well here is a good place to start. When building a 3d printer, choosing the right parts is crucial to ensure that the printer functions effectively. How do you make your own 3d printer? The heygears reflex rs is a solidly built machine that follows the general style of a formlabs 3d printer at a fraction of the cost. Put every single nut yourself. The heygears reflex rs is a solidly built machine that follows the general style of a formlabs 3d printer at a fraction of the cost. So this time i made a 3d printer from some waste/residual wood, some recycled electronic parts and about 120$. Anyone can easily build their very own 3d printer in just one day. There are smaller. I’ll go a bit into different types of 3d printers and discuss the choices i made. There are two ways to build a 3d printer from the start. A 3d concrete printer is being used to build a home in perth's north. This not only enables you to better understand the way things work and how to. How do you. There are two ways to build a 3d printer from the start. In this section, we will discuss the most important parts of a 3d printer and what to. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. When building a 3d. Anyone can easily build their very own 3d printer in just one day. This not only enables you to better understand the way things work and how to. Tyson build plates are available for bambu lab 3d printers, and limited production runs can be made for standard 120 mm, 180 mm, 250 mm and 300 mm plates to support. So. The heygears reflex rs is a solidly built machine that follows the general style of a formlabs 3d printer at a fraction of the cost. The first way is to start building the 3d printer all by yourself. Well here is a good place to start. Wa has about 4,000 active listings for homes, well below the 10,000 that experts. We’ll go through some assembly tips for popular kit printers, and i’ll also. Tyson build plates are available for bambu lab 3d printers, and limited production runs can be made for standard 120 mm, 180 mm, 250 mm and 300 mm plates to support. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall. Well here is a good place to start. The resulting powder can then be fed into 3d printers. The heygears reflex rs is a solidly built machine that follows the general style of a formlabs 3d printer at a fraction of the cost. By building your own 3d printer you get to learn about every aspect of the machine and. I’ll go a bit into different types of 3d printers and discuss the choices i made. So this time i made a 3d printer from some waste/residual wood, some recycled electronic parts and about 120$. We’ll go through some assembly tips for popular kit printers, and i’ll also. In this article, i’ll show you how you can successfully build or. This video shows you how to build a printer without the 3d printed parts but it's recommended you obtain the 3d printer parts from a local makerspace or even places like office depot does. These machines essentially weld the powder into layers half the thickness of a human hair and set down each layer, one. I’ll go a bit into. The resulting powder can then be fed into 3d printers. Tyson build plates are available for bambu lab 3d printers, and limited production runs can be made for standard 120 mm, 180 mm, 250 mm and 300 mm plates to support. A 3d concrete printer is being used to build a home in perth's north. In this instructable i will. This not only enables you to better understand the way things work and how to. While it may seem intimidating at first, it’s actually. By building your own 3d printer you get to learn about every aspect of the machine and process. In this instructable i will show you how i made it with only hand tools, i am an. The resulting powder can then be fed into 3d printers. Tyson build plates are available for bambu lab 3d printers, and limited production runs can be made for standard 120 mm, 180 mm, 250 mm and 300 mm plates to support. Put every single nut yourself. There are smaller and larger printers on the market, but this. There are two ways to build a 3d printer from the start. So this time i made a 3d printer from some waste/residual wood, some recycled electronic parts and about 120$. Rating 3.6 out of 5 stars with 9 reviews (9) $1,499.99 your price for this item is $1,499.99. When building a 3d printer, choosing the right parts is crucial to ensure that the printer functions effectively. The centauri carbon boasts a build area of 256x256x256mm, which is the typical size for a lot of fdm 3d printers. So you want to build an fff / fdm 3d printer from scratch? A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. Anyone can easily build their very own 3d printer in just one day.Building a 3D Printer Under 299 33 Steps (with Pictures) Instructables

DIY 3D Printer How to Make a 3D Printer That Anyone Can Do 7 Steps

How to Design and Build a 3D Printer 10 Steps (with Pictures

DIY 3D Printer How to Make a 3D Printer That Anyone Can Do 7 Steps

The Best Ideas for Diy 3d Printer Plans Home, Family, Style and Art Ideas

200 DIY 3D Printer Build 8 Steps (with Pictures) Instructables

How to Build a 3D Printer

The Best DIY 3D Printer Designs of 2020

How to Build a 3D Printer

CoLiDo DIY 3D Printer with Filament Build your own 3D Printer with

These Machines Essentially Weld The Powder Into Layers Half The Thickness Of A Human Hair And Set Down Each Layer, One.

Most Comprehensive Guide On How To Build A 3D Printer On The Internet!

How Do You Make Your Own 3D Printer?

I’ll Go A Bit Into Different Types Of 3D Printers And Discuss The Choices I Made.

Related Post: