Build A Plasma Cutter

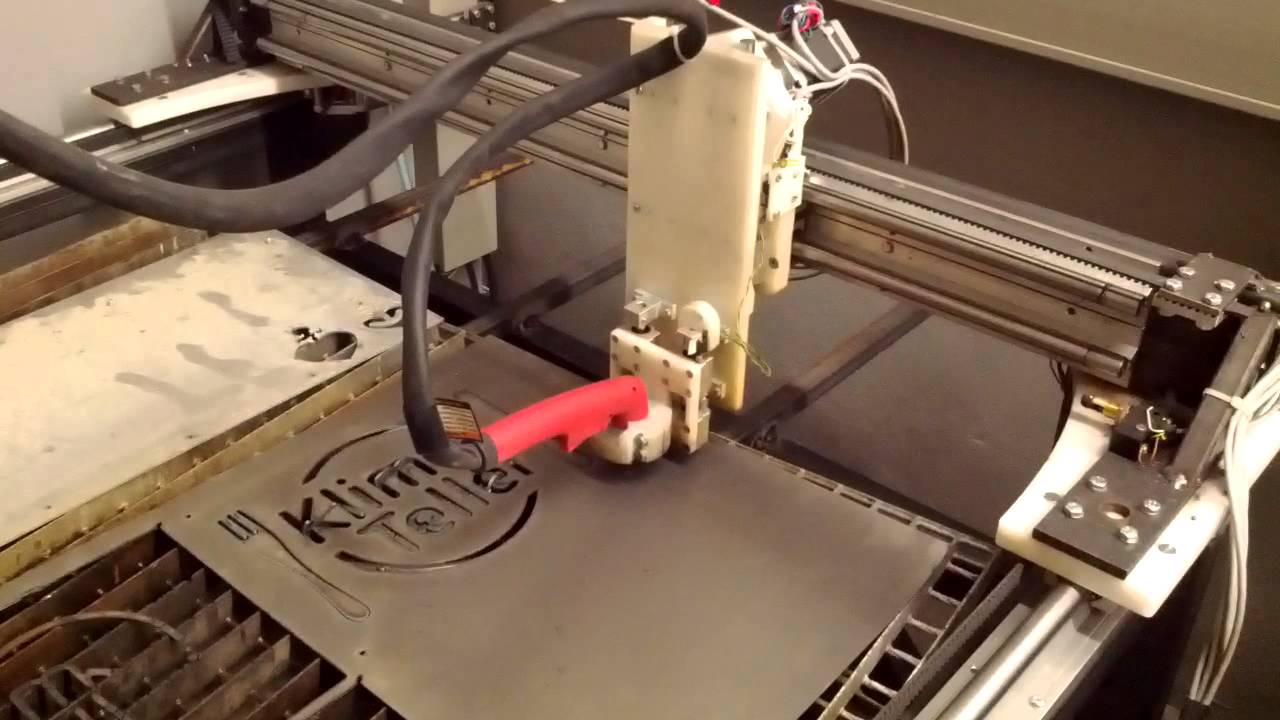

Build A Plasma Cutter - Manufacturing positions are challenging to fill and retain amidst a growing labor shortage. A torch height controller helps improve plasma cut quality and can save a cnc machine from crashing. I started by collecting parts from old microwaves, stoves, water heaters, air conditioners, car parts and more in the hopes of creating a low budget way to create a plasma cutter for myself. Using regular fuel combustion, rockets have a maximum matter flow velocity of roughly 2.7 miles per second (4.5 kilometers per second), but the plasma engine is capable of. I’m going to show you how to make yourself and build at home and very cheap and efficient cutting plasma machine that works very efficiently even if it’s made completely with. So i decided to build my. The plasma cutter is responsible for generating the plasma jet that melts the material being cut. Metal fabricators who want to increase productivity and product throughput choose cobot plasma. Discover essential tips for step 1:. Lucky enough, [plasanator] posted their tutorial for how to make a plasma cutter, showing the steps through which they gathered parts from “old microwaves, stoves, water heaters, air. This design doesn't require you to know electronics or need any. For those unfortunate few of you who don’t already have a plasma cutter sitting around, [jandgse812] is here to help. Discover essential tips for step 1:. From materials to final assembly, we cover everything you need for success. Metal fabricators who want to increase productivity and product throughput choose cobot plasma. This is an effort to gather as much info as possible in one place for those interested in building a diy cnc plasma cutter, or retrofitting and old plasma machine. So i decided to build my. Manufacturing positions are challenging to fill and retain amidst a growing labor shortage. What i can promise you is that building your own plasma cutting table will give you superior knowledge on how your instrument works, which will allow you to quickly troubleshoot. Best of all, it will only cost you. Manufacturing positions are challenging to fill and retain amidst a growing labor shortage. Metal fabricators who want to increase productivity and product throughput choose cobot plasma. Discover essential tips for step 1:. This is an effort to gather as much info as possible in one place for those interested in building a diy cnc plasma cutter, or retrofitting and old. The plasma cutter is responsible for generating the plasma jet that melts the material being cut. Manufacturing positions are challenging to fill and retain amidst a growing labor shortage. If i’m gonna make video’s again, i’ll make it easy on myself and get a cnc plasma cutter, and then i looked at the prices…. Building and operating your own cnc. Discover essential tips for step 1:. From materials to final assembly, we cover everything you need for success. Building and operating your own cnc plasma table involves several key steps and considerations. This design doesn't require you to know electronics or need any. Controlled by a computer, the cutter can follow intricate paths and make. So i recently acquired a new plasma cutter, which is totally going to revolutionize my workflow. The plasma cutter is responsible for generating the plasma jet that melts the material being cut. From materials to final assembly, we cover everything you need for success. Metal fabricators who want to increase productivity and product throughput choose cobot plasma. What i can. What i can promise you is that building your own plasma cutting table will give you superior knowledge on how your instrument works, which will allow you to quickly troubleshoot. Building and operating your own cnc plasma table involves several key steps and considerations. From materials to final assembly, we cover everything you need for success. This is an effort. It is also utilized in demolition to quickly cut through thick metal structures, as well as in hvac, mining, energy, shipbuilding, and other industries for tasks such as cutting wire. This is an effort to gather as much info as possible in one place for those interested in building a diy cnc plasma cutter, or retrofitting and old plasma machine.. A torch height controller helps improve plasma cut quality and can save a cnc machine from crashing. Best of all, it will only cost you. Manufacturing positions are challenging to fill and retain amidst a growing labor shortage. For those unfortunate few of you who don’t already have a plasma cutter sitting around, [jandgse812] is here to help. Start by. Manufacturing positions are challenging to fill and retain amidst a growing labor shortage. What i can promise you is that building your own plasma cutting table will give you superior knowledge on how your instrument works, which will allow you to quickly troubleshoot. From materials to final assembly, we cover everything you need for success. Start by designing the table. The plasma cutter is responsible for generating the plasma jet that melts the material being cut. It is also utilized in demolition to quickly cut through thick metal structures, as well as in hvac, mining, energy, shipbuilding, and other industries for tasks such as cutting wire. From materials to final assembly, we cover everything you need for success. This is. Start by designing the table frame, typically using sturdy materials like steel or. If i’m gonna make video’s again, i’ll make it easy on myself and get a cnc plasma cutter, and then i looked at the prices…. This is an effort to gather as much info as possible in one place for those interested in building a diy cnc. Lucky enough, [plasanator] posted their tutorial for how to make a plasma cutter, showing the steps through which they gathered parts from “old microwaves, stoves, water heaters, air. A torch height controller helps improve plasma cut quality and can save a cnc machine from crashing. But in order to use these guys you need a surface for your material that won't reflect the arc. Building and operating your own cnc plasma table involves several key steps and considerations. Best of all, it will only cost you. It is also utilized in demolition to quickly cut through thick metal structures, as well as in hvac, mining, energy, shipbuilding, and other industries for tasks such as cutting wire. Joe @harbaughsworkshop will show you how to build your own cnc plasma cutter table, following the plan provided by jd’s garage @jdsgarage701. Controlled by a computer, the cutter can follow intricate paths and make. Using regular fuel combustion, rockets have a maximum matter flow velocity of roughly 2.7 miles per second (4.5 kilometers per second), but the plasma engine is capable of. From materials to final assembly, we cover everything you need for success. What i can promise you is that building your own plasma cutting table will give you superior knowledge on how your instrument works, which will allow you to quickly troubleshoot. I’m going to show you how to make yourself and build at home and very cheap and efficient cutting plasma machine that works very efficiently even if it’s made completely with. He walks you through the process of building your own. For those unfortunate few of you who don’t already have a plasma cutter sitting around, [jandgse812] is here to help. Start by designing the table frame, typically using sturdy materials like steel or. This is an effort to gather as much info as possible in one place for those interested in building a diy cnc plasma cutter, or retrofitting and old plasma machine.Best DIY CNC Plasma Cutter YouTube

How To Build A Cnc Plasma Cutter

How To Build A Cnc Plasma Cutter

How to Build a CNC Plasma Cutter YouTube

How to build a plasma cutter

Build a CNC Plasma Cutter for under 1,000 YouTube

How To Build A Cnc Plasma Cutter

How To Build A Cnc Plasma Cutter

How To Build A Cnc Plasma Cutter

DIY Plasma Cutter Guide YouTube

The Plasma Cutter Is Responsible For Generating The Plasma Jet That Melts The Material Being Cut.

This Is An Effort To Gather As Much Info As Possible In One Place For Those Interested In Building A Diy Cnc Plasma Cutter, Or Retrofitting And Old Plasma Machine.

This Design Doesn't Require You To Know Electronics Or Need Any.

Manufacturing Positions Are Challenging To Fill And Retain Amidst A Growing Labor Shortage.

Related Post: