Build Cnc Machine

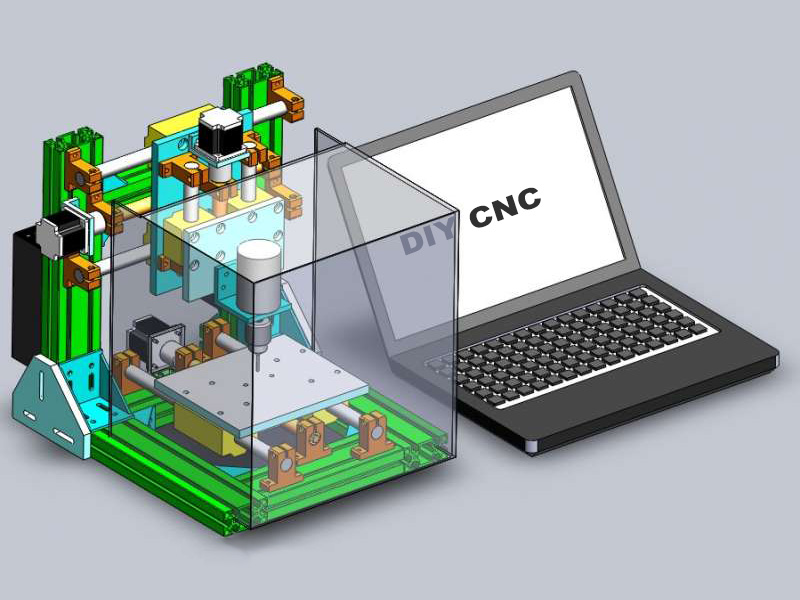

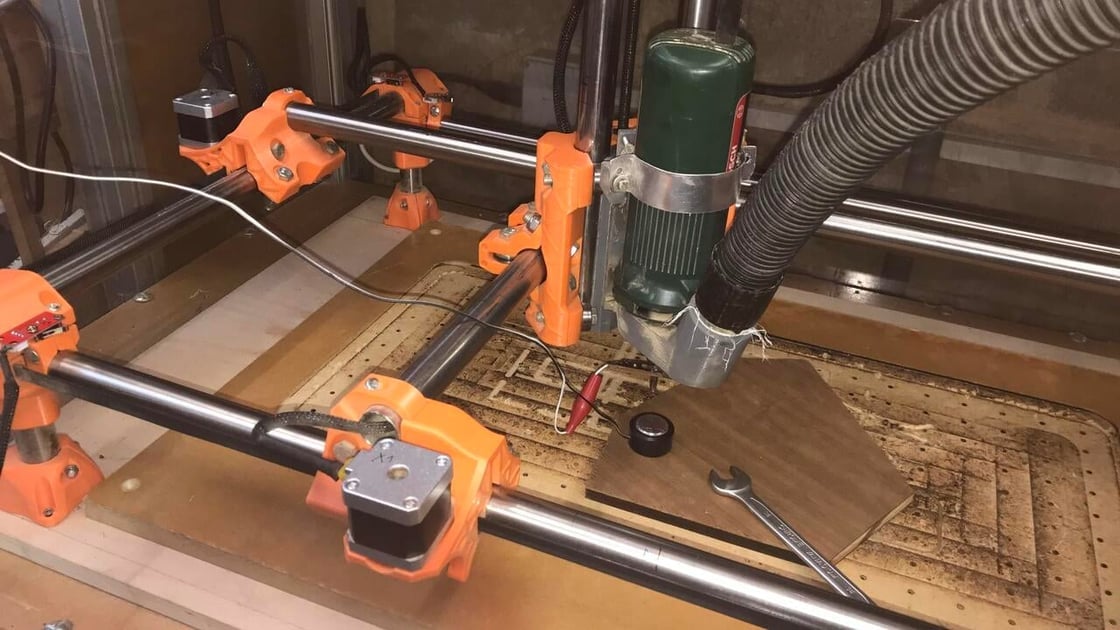

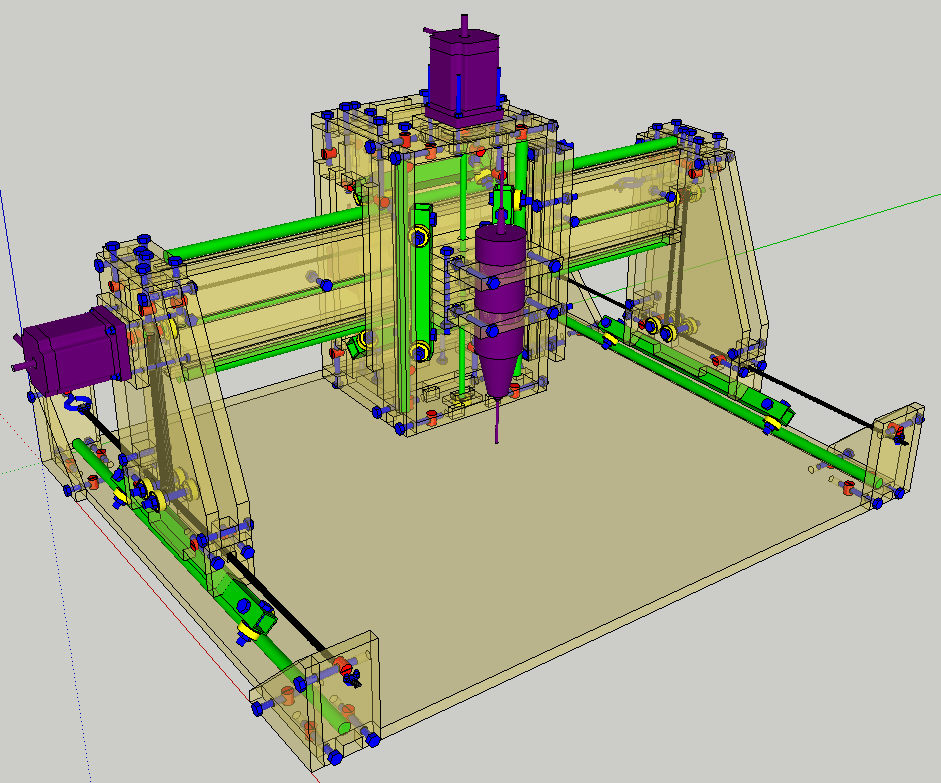

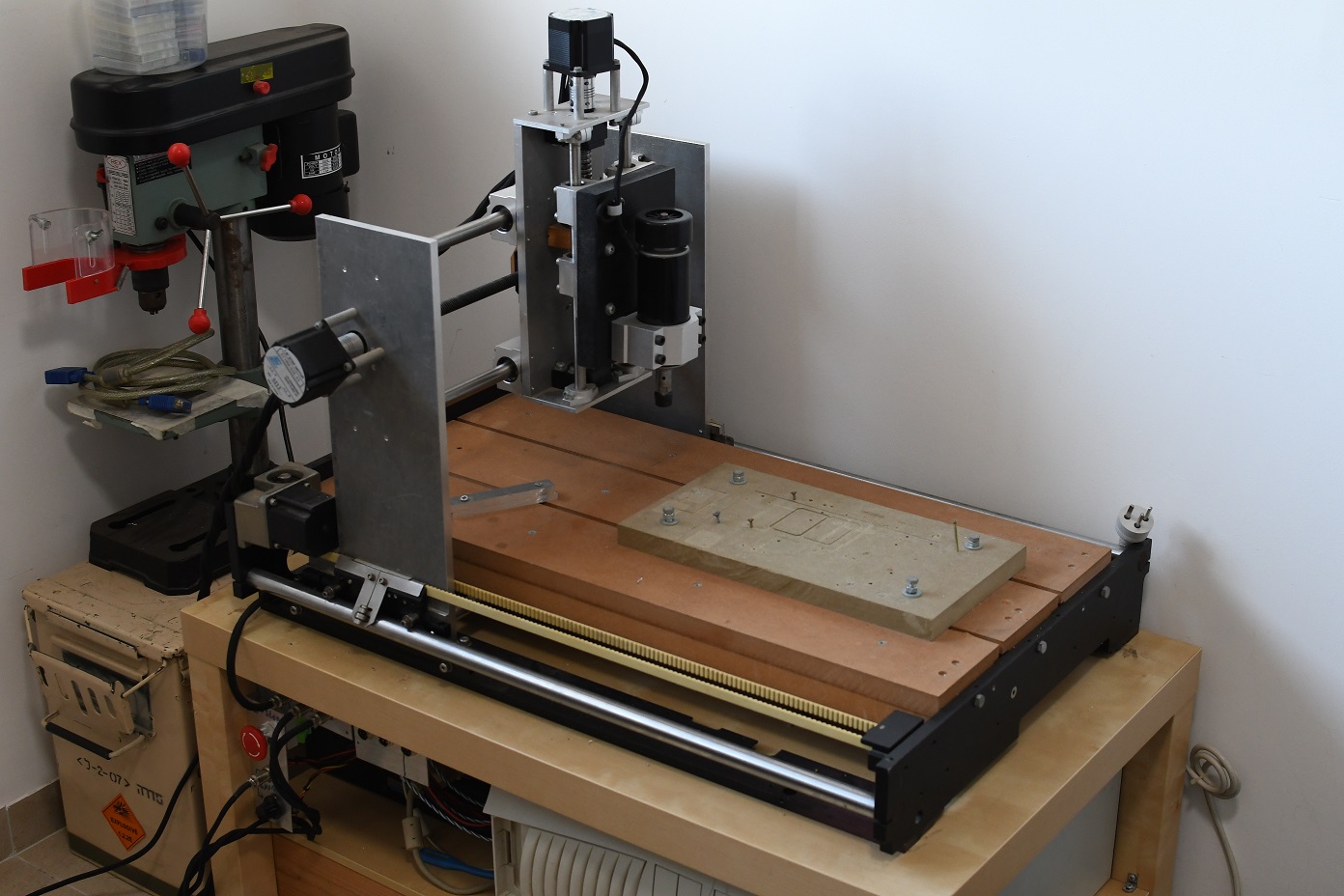

Build Cnc Machine - This instructable outlines the assembly process of my 2nd generation cnc machine which i designed to be simple to build and quiet enough to be apartment. Building a diy cnc machine helps you understand its inner workings. I'm not sold on cnc, b. Cnc machines operate based on digital files that contain detailed instructions about cutting trajectories and tooling. In this new series, luke niels from crusader machining dives deep into cnc lathe machining, covering everything from machine setup and programming to turning, threading,. In this guide, we will explore the possibilities of building your. With a working area of 24x48, you can build this for a lot less than the cost of a similar commercial cnc router. Cnc machining of acrylic typically requires a steady feed rate. A compact router, baltic birch plywood, some basic hardware,. A high performance cnc machine for woodworking, milling aluminum, and making awesome things! Make your own diy cnc: Using mach 4 is a bit like using windows to set up a file server. Cnc machines operate based on digital files that contain detailed instructions about cutting trajectories and tooling. Building a diy cnc machine helps you understand its inner workings. A strong easy to build shop cnc router that can be sized to suit your needs. Cnc machining of acrylic typically requires a steady feed rate. But as always, when you build a “thing”, you inevitably figure out how to build a better “thing” in the process, so here we are with cody’s cnc machine v2.0. I'm not sold on cnc, b. Having obtained a bunch of linear rails, ball screws and servo motors, i figured i might as well try to build a cnc router out of it. In this new series, luke niels from crusader machining dives deep into cnc lathe machining, covering everything from machine setup and programming to turning, threading,. Make your own diy cnc: Compass is a diy handheld cnc router designed to make cnc machining more accessible. This instructable outlines the assembly process of my 2nd generation cnc machine which i designed to be simple to build and quiet enough to be apartment. Having obtained a bunch of linear rails, ball screws and servo motors, i figured i. Having obtained a bunch of linear rails, ball screws and servo motors, i figured i might as well try to build a cnc router out of it. Operate your cnc seamlessly through multiple control modes: Unlike traditional cncs that move a cutting tool within a fixed workspace,. In short what is required is a controller capable of three axes of. In short what is required is a controller capable of three axes of control (with pulsed step and direction inputs) and motors with about 100 oz/in holding torque. A compact router, baltic birch plywood, some basic hardware,. Operate your cnc seamlessly through multiple control modes: Cnc machines operate based on digital files that contain detailed instructions about cutting trajectories and. Use our resources to learn all. This instructable outlines the assembly process of my 2nd generation cnc machine which i designed to be simple to build and quiet enough to be apartment. This guide goes through all the steps to build your own cnc machine from scratch. In this guide, we will explore the possibilities of building your. A high. Cnc machines operate based on digital files that contain detailed instructions about cutting trajectories and tooling. A strong easy to build shop cnc router that can be sized to suit your needs. All moving parts of the diy cnc router are running on ball bearings while the structural parts are made with natural. Building a diy cnc machine helps you. With a working area of 24x48, you can build this for a lot less than the cost of a similar commercial cnc router. With the right knowledge and resources, you can create a customized cnc machine right in your own home. Using mach 4 is a bit like using windows to set up a file server. This instructable outlines the. But as always, when you build a “thing”, you inevitably figure out how to build a better “thing” in the process, so here we are with cody’s cnc machine v2.0. You can assemble it from a kit or build it from plans. Cnc machining of acrylic typically requires a steady feed rate. The latest cnc machines are controlled via gcode. Use our resources to learn all. Many new features have been incorporated into the ox to make it a. With a working area of 24x48, you can build this for a lot less than the cost of a similar commercial cnc router. In short what is required is a controller capable of three axes of control (with pulsed step and. A compact router, baltic birch plywood, some basic hardware,. You can assemble it from a kit or build it from plans. Using mach 4 is a bit like using windows to set up a file server. Adding cnc to your shop doesn’t have to cost a small fortune; Compass is a diy handheld cnc router designed to make cnc machining. With the right knowledge and resources, you can create a customized cnc machine right in your own home. This guide goes through all the steps to build your own cnc machine from scratch. Operate your cnc seamlessly through multiple control modes: Many new features have been incorporated into the ox to make it a. I'm not sold on cnc, b. Cnc machining of acrylic typically requires a steady feed rate. I'm not sold on cnc, b. A compact router, baltic birch plywood, some basic hardware,. A strong easy to build shop cnc router that can be sized to suit your needs. Use our resources to learn all. In this project, i show you how i built my diy cnc machine. Building a diy cnc machine helps you understand its inner workings. All moving parts of the diy cnc router are running on ball bearings while the structural parts are made with natural. Many new features have been incorporated into the ox to make it a. With the right knowledge and resources, you can create a customized cnc machine right in your own home. Operate your cnc seamlessly through multiple control modes: Make your own diy cnc: Having obtained a bunch of linear rails, ball screws and servo motors, i figured i might as well try to build a cnc router out of it. Using mach 4 is a bit like using windows to set up a file server. Unlike traditional cncs that move a cutting tool within a fixed workspace,. But as always, when you build a “thing”, you inevitably figure out how to build a better “thing” in the process, so here we are with cody’s cnc machine v2.0.Build Your Own CNC Machine. 20 Steps (with Pictures) Instructables

How to build CNC machine DIY YouTube

Making a DIY CNC machine with limited tools YouTube

How to Build a CNC Machine from Scratch? DIY Guide

DIY CNC Router/Machine How to Build Your Own All3DP

How to Make a Three Axis CNC Machine (Cheaply and Easily) 12 Steps

DIY CNC build. How to make your own CNC machine YouTube

DIY CNC Machine for Hobby Use Toli's DIY

Building Your Own CNC Router/milling Machine 11 Steps (with Pictures

DIY CNC Router Part 2 // Building a Small CNC Router YouTube

In Short What Is Required Is A Controller Capable Of Three Axes Of Control (With Pulsed Step And Direction Inputs) And Motors With About 100 Oz/In Holding Torque.

With A Working Area Of 24X48, You Can Build This For A Lot Less Than The Cost Of A Similar Commercial Cnc Router.

This Guide Goes Through All The Steps To Build Your Own Cnc Machine From Scratch.

Adding Cnc To Your Shop Doesn’t Have To Cost A Small Fortune;

Related Post: