Build Plate Adhesion

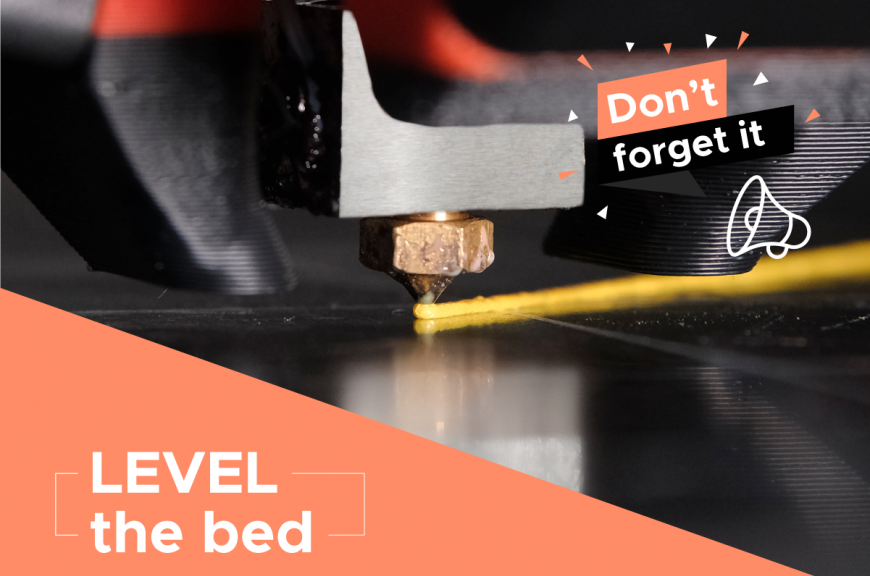

Build Plate Adhesion - Over time oils from your skin, as well as other residues and contaminants, can transfer to the surface of your build plate and interfere with bed adhesion. In cura, brim is a setting that instructs the printer to print multiple lines around the model for support. Build plate adhesion and getting the first layers to stick are critical to successful printing. Glass is what comes stock on most printers. There are three main types of build plate adhesion settings that can help your 3d prints stick to the bed and come out more successfully. Why is pla not sticking to pei sheet? Below you will find a guide with common build plates and information on when you should (and shouldn't) be using them. Right off the bat, bed adhesion refers to the ability of the 3d printed plastic to adhere to the build plate while printing. The first part of this article recommends the best build plates for each filament, and. There are different types of 3d printing surfaces to help. Pei is quickly becoming the gold standard print surface for 3d printing, but what happens when your print materials don’t stick? Have you ever experienced the issue of your resin prints sticking to the fep film instead of the build plate? Glass is what comes stock on most printers. First, optimize the build plate temperature to get the best result. Here’s my recommendations for the best 3d printer build surfaces and plates for every use. Printing a brim primes the printer nozzle, assists with bed adhesion, prevents model. There are three main types of build plate adhesion settings that can help your 3d prints stick to the bed and come out more successfully. Why is pla not sticking to pei sheet? Just about every single material type has different build plate adhesion requirements. It's crucial to ensure your build plate is clean and free from any contaminants. It's crucial to ensure your build plate is clean and free from any contaminants. If you’ve experienced this yourself, you’ll know exactly how annoying it can be to forcibly rip your model from the build plate only to find out a chunk of it left stuck to the bottom. In cura, brim is a setting that instructs the printer to. It's crucial to ensure your build plate is clean and free from any contaminants. There are different types of 3d printing surfaces to help. The first part of this article recommends the best build plates for each filament, and. The adhesion depends on the type of filament, type of bed, and the. Just about every single material type has different. Follow these steps for optimal adhesion: While it does a pretty. While not quite as common as low adhesion or warping, prints sticking excessively to your print bed is still a problem. The adhesion depends on the type of filament, type of bed, and the. There are three main types of build plate adhesion settings that can help your 3d. There are three main types of build plate adhesion settings that can help your 3d prints stick to the bed and come out more successfully. Here’s my recommendations for the best 3d printer build surfaces and plates for every use. Glass is what comes stock on most printers. There are different types of 3d printing surfaces to help. This problem. In cura, brim is a setting that instructs the printer to print multiple lines around the model for support. Why is pla not sticking to pei sheet? This step in the print profile assistant optimizes build plate adhesion. Pei is quickly becoming the gold standard print surface for 3d printing, but what happens when your print materials don’t stick? Glass. Have you ever experienced the issue of your resin prints sticking to the fep film instead of the build plate? Below you will find a guide with common build plates and information on when you should (and shouldn't) be using them. When the object is printed, go. Over time oils from your skin, as well as other residues and contaminants,. In cura, brim is a setting that instructs the printer to print multiple lines around the model for support. Below you will find a guide with common build plates and information on when you should (and shouldn't) be using them. Just about every single material type has different build plate adhesion requirements. Printing a brim primes the printer nozzle, assists. It's crucial to ensure your build plate is clean and free from any contaminants. Bed adhesion is simply the ability of 3d printed plastic to cling or “stick” to the build plate during a print. This problem is related to bed adhesion, similar to the issue of resin prints not sticking to supports as well as resin print warping. Have. If you’ve experienced this yourself, you’ll know exactly how annoying it can be to forcibly rip your model from the build plate only to find out a chunk of it left stuck to the bottom. An adhesion assistant is a term we’ve given to the three build plate adhesion types, including skirts, brims, and rafts, that can be found in. Why is pla not sticking to pei sheet? We will go over some basic settings for different material types later in this page, but if you are working. Over time oils from your skin, as well as other residues and contaminants, can transfer to the surface of your build plate and interfere with bed adhesion. Having a clean build plate. The adhesion depends on the type of filament, type of bed, and the. There are different types of 3d printing surfaces to help. This step in the print profile assistant optimizes build plate adhesion. While not quite as common as low adhesion or warping, prints sticking excessively to your print bed is still a problem. Pei is quickly becoming the gold standard print surface for 3d printing, but what happens when your print materials don’t stick? If you’ve experienced this yourself, you’ll know exactly how annoying it can be to forcibly rip your model from the build plate only to find out a chunk of it left stuck to the bottom. First, optimize the build plate temperature to get the best result. Glass is what comes stock on most printers. Use windex®, ipa (isopropyl alcohol), or alcohol. Having a clean build plate is the first step to achieving good bed adhesion. Aspects of the design of the 3d model and how it is oriented on the build plate can. Just about every single material type has different build plate adhesion requirements. In cura, brim is a setting that instructs the printer to print multiple lines around the model for support. The first part of this article recommends the best build plates for each filament, and. Over time oils from your skin, as well as other residues and contaminants, can transfer to the surface of your build plate and interfere with bed adhesion. Build plate adhesion and getting the first layers to stick are critical to successful printing.3d printing build plate adhesion

Creality Print Basics Build Plate Adhesion Types YouTube

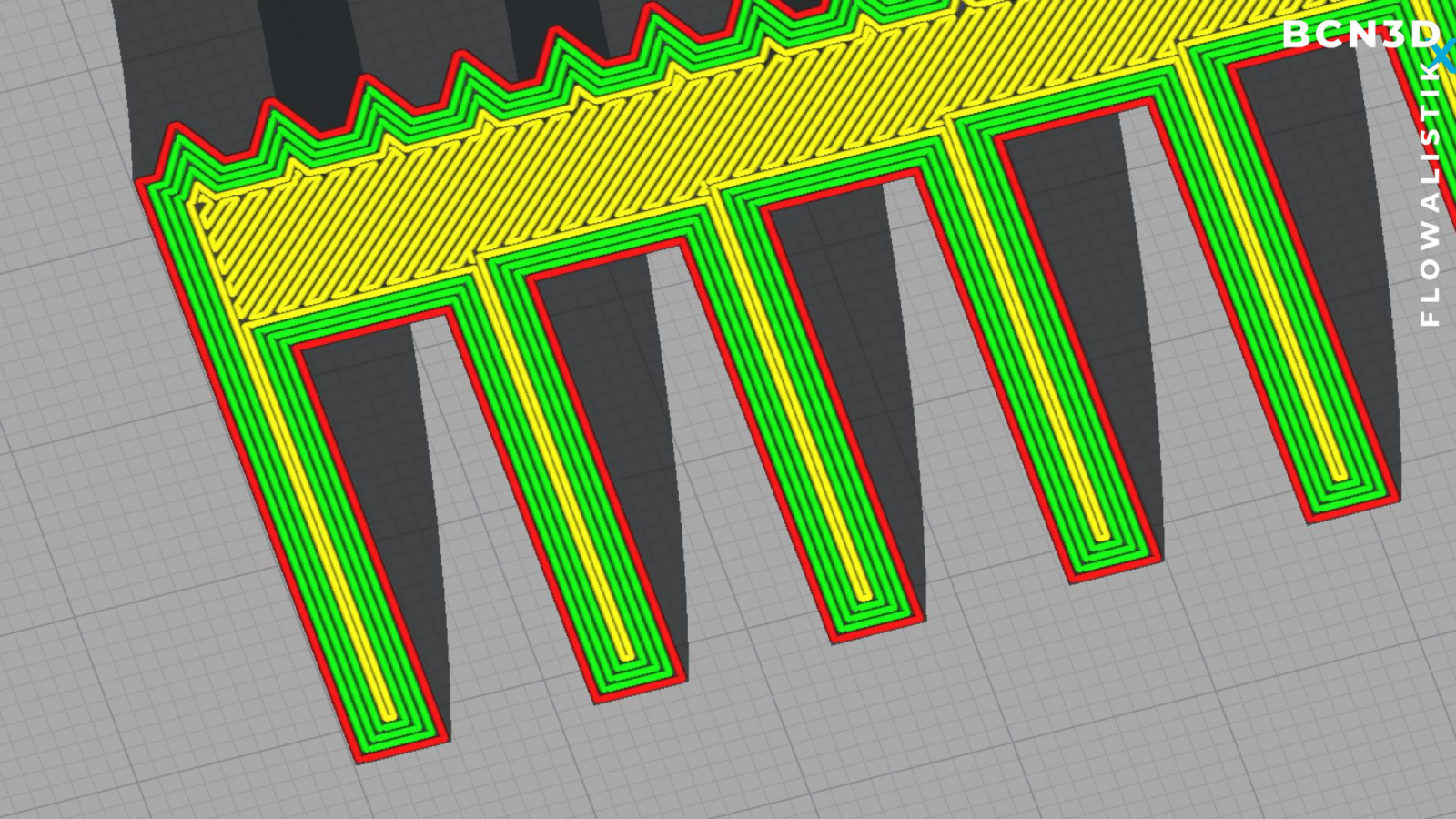

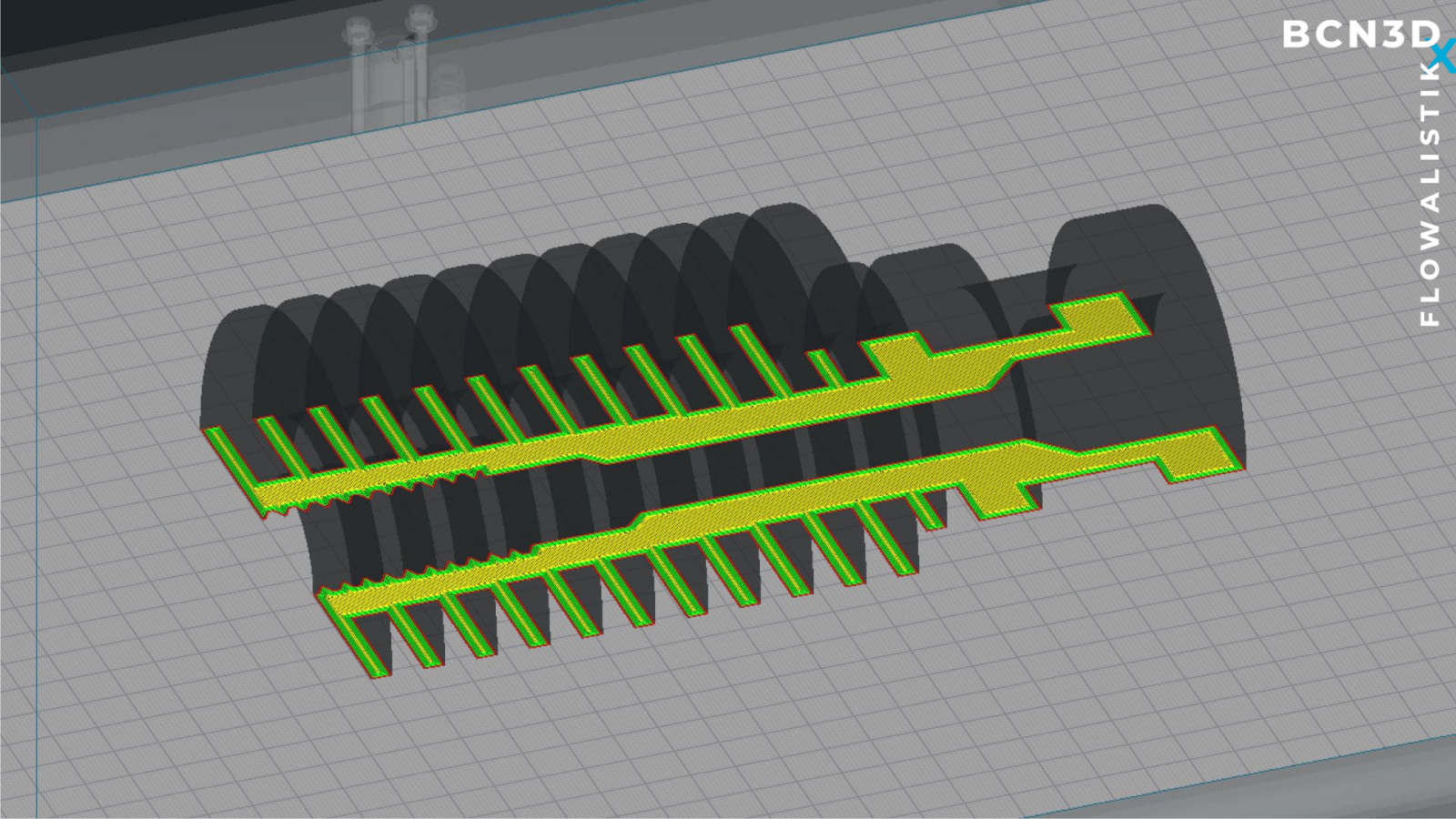

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

Cura Build Plate Adhesion Types & Settings Guide MeaD MaDe

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

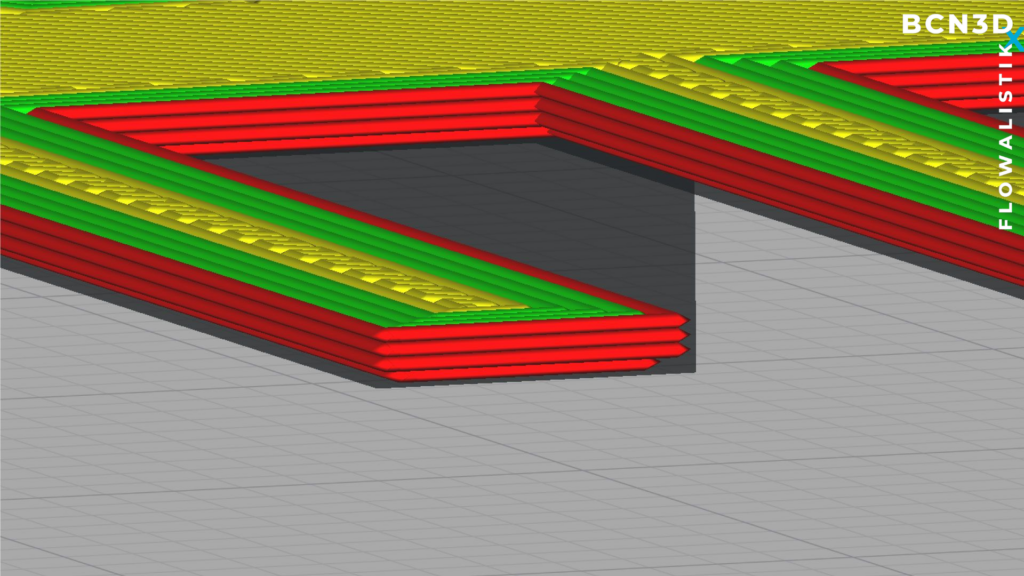

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

Mengenal MacamMacam Build Plate Adhesion Tutorial 3D Printer YouTube

How to Get the Perfect Build Plate Adhesion Settings & Improve Bed

TYPES OF BUILD PLATE ADHESION HOW TO CHOOSE? PEFRECT FIRST LAYER

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

It's Crucial To Ensure Your Build Plate Is Clean And Free From Any Contaminants.

We Will Go Over Some Basic Settings For Different Material Types Later In This Page, But If You Are Working.

Follow These Steps For Optimal Adhesion:

While It Does A Pretty.

Related Post: