Build Plate Material For Pla Heated Metal

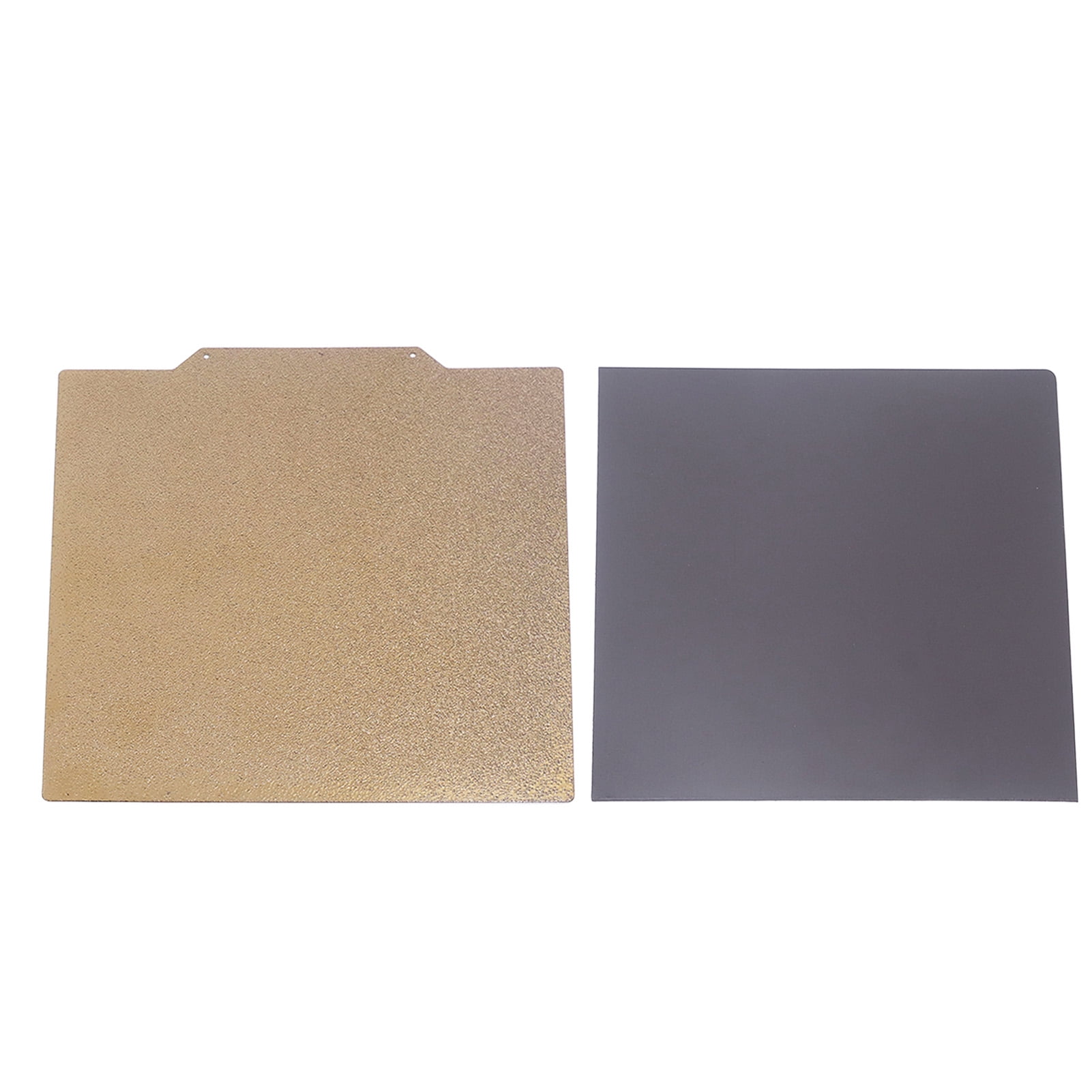

Build Plate Material For Pla Heated Metal - The halvorsen company provides plate rolling services, working with carbon steel, carbon alloys, stainless steel, stainless alloys, aluminum, copper, and most all plate materials, ranging from. It's very stable with little thermal expansion & holds up to 120 or 130 c if i remember. Fr4 is a heat resistant resin with fiber glass added. So instead of just buying a new pcb bed, i am. Accurate metals offers oxyfuel flame cutting, plasma cutting, heat treating, blanchard grinding, abrasive blasting, and more manufacturing services. Plate burning is a process used to cut steel and aluminum to a shape utilizing a plasma torch. The answer depends a bit on the type of pla (supplier of specific filament), type of machine, type of build platform, size of model and ambient temperature. This process is crucial for creating parts with curved or angled surfaces. I have been using wham bam pex build plates for the past 4 years for printing pla. Pei ultem (polyetherimide) from primacreator is a reusable, relatively maintenance free, build surface for both abs (with a heated bed) and pla (hot or cold), other materials such as metal,. We offer a variety of build plates compatible with a wide range of 3d printer models and materials, including pla, abs, petg, and more. It's very stable with little thermal expansion & holds up to 120 or 130 c if i remember. Pei is very durable (i scrape stuff off with a scraper blade and wipe down with acetone) and abs and pla (and others i believe) stick to it. 3d printer build plate, 365 x 365mm double sided magnetic build plate for prusa xl, heated bed, pei spring steel sheet compatible with pla, petg, abs, tpu, tpe, hps,. Never used glue or anything else to improve adhesion. This process is crucial for creating parts with curved or angled surfaces. Fr4 is a heat resistant resin with fiber glass added. What is the best build plate for pla? Depend on material, pla usually is fine, abs and nylon need some adhesive or it won't stick to bare glass. Accurate metals offers oxyfuel flame cutting, plasma cutting, heat treating, blanchard grinding, abrasive blasting, and more manufacturing services. Plate burning is a process used to cut steel and aluminum to a shape utilizing a plasma torch. This process is crucial for creating parts with curved or angled surfaces. Never used glue or anything else to improve adhesion. Metal plates can be bent or formed into specific shapes using press brakes or rolling machines. It is just my opinion,. I have been using wham bam pex build plates for the past 4 years for printing pla. Metal plates can be bent or formed into specific shapes using press brakes or rolling machines. We offer a variety of build plates compatible with a wide range of 3d printer models and materials, including pla, abs, petg, and more. Pei is very. Never used glue or anything else to improve adhesion. The halvorsen company provides plate rolling services, working with carbon steel, carbon alloys, stainless steel, stainless alloys, aluminum, copper, and most all plate materials, ranging from. It's very stable with little thermal expansion & holds up to 120 or 130 c if i remember. This process is crucial for creating parts. Pei ultem (polyetherimide) from primacreator is a reusable, relatively maintenance free, build surface for both abs (with a heated bed) and pla (hot or cold), other materials such as metal,. Its used in pcb's as the board the copper is mounted. Works perfectly with a heated bed at 50°c. Fr4 is a heat resistant resin with fiber glass added. 3d. So instead of just buying a new pcb bed, i am. Its used in pcb's as the board the copper is mounted. Metal plates can be bent or formed into specific shapes using press brakes or rolling machines. Accurate metals offers oxyfuel flame cutting, plasma cutting, heat treating, blanchard grinding, abrasive blasting, and more manufacturing services. Depend on material, pla. So instead of just buying a new pcb bed, i am. Fr4 is a heat resistant resin with fiber glass added. This process is crucial for creating parts with curved or angled surfaces. Accurate metals offers oxyfuel flame cutting, plasma cutting, heat treating, blanchard grinding, abrasive blasting, and more manufacturing services. Metal plates can be bent or formed into specific. Pei is very durable (i scrape stuff off with a scraper blade and wipe down with acetone) and abs and pla (and others i believe) stick to it. Depend on material, pla usually is fine, abs and nylon need some adhesive or it won't stick to bare glass. Its used in pcb's as the board the copper is mounted. A. Pei ultem (polyetherimide) from primacreator is a reusable, relatively maintenance free, build surface for both abs (with a heated bed) and pla (hot or cold), other materials such as metal,. This process is crucial for creating parts with curved or angled surfaces. Accurate metals offers oxyfuel flame cutting, plasma cutting, heat treating, blanchard grinding, abrasive blasting, and more manufacturing services.. Pei ultem (polyetherimide) from primacreator is a reusable, relatively maintenance free, build surface for both abs (with a heated bed) and pla (hot or cold), other materials such as metal,. The answer depends a bit on the type of pla (supplier of specific filament), type of machine, type of build platform, size of model and ambient temperature. Never used glue. A glass build plate with a smooth surface is generally considered the best for pla due to its excellent adhesion and ease of use. Metal plates can be bent or formed into specific shapes using press brakes or rolling machines. Pei is very durable (i scrape stuff off with a scraper blade and wipe down with acetone) and abs and. It's very stable with little thermal expansion & holds up to 120 or 130 c if i remember. We offer a variety of build plates compatible with a wide range of 3d printer models and materials, including pla, abs, petg, and more. Plate burning is a process used to cut steel and aluminum to a shape utilizing a plasma torch. This process is crucial for creating parts with curved or angled surfaces. I have been using wham bam pex build plates for the past 4 years for printing pla. 3d printer build plate, 365 x 365mm double sided magnetic build plate for prusa xl, heated bed, pei spring steel sheet compatible with pla, petg, abs, tpu, tpe, hps,. Metal plates can be bent or formed into specific shapes using press brakes or rolling machines. Never used glue or anything else to improve adhesion. It is just my opinion, but there is no universal answer. The halvorsen company provides plate rolling services, working with carbon steel, carbon alloys, stainless steel, stainless alloys, aluminum, copper, and most all plate materials, ranging from. The answer depends a bit on the type of pla (supplier of specific filament), type of machine, type of build platform, size of model and ambient temperature. Pei is very durable (i scrape stuff off with a scraper blade and wipe down with acetone) and abs and pla (and others i believe) stick to it. Works perfectly with a heated bed at 50°c. What is the best build plate for pla? Whether you need a glass plate for a smooth finish or a. Its used in pcb's as the board the copper is mounted.Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

Metal Build Plates Additive Plus

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

Petg Sheet

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

PLA/ABS Build Plate (Plex3d/gekonweld) 20x20x1 Filament Shop

2024 3D Printer Build Plate 410x430MM Double Sided PEI Spring Steel

ABS Plastic Sheet [PlaPlate] White Scratch Build Materials

3D Printer Build Plate 410x430MM Double Sided PEI Spring Steel Plate

So Instead Of Just Buying A New Pcb Bed, I Am.

Accurate Metals Offers Oxyfuel Flame Cutting, Plasma Cutting, Heat Treating, Blanchard Grinding, Abrasive Blasting, And More Manufacturing Services.

Fr4 Is A Heat Resistant Resin With Fiber Glass Added.

A Glass Build Plate With A Smooth Surface Is Generally Considered The Best For Pla Due To Its Excellent Adhesion And Ease Of Use.

Related Post:

![ABS Plastic Sheet [PlaPlate] White Scratch Build Materials](https://www.museigenhobby.com/wp-content/uploads/2018/06/ABS-Plastic-Sheet.jpg)