Build Plate Material For Pla

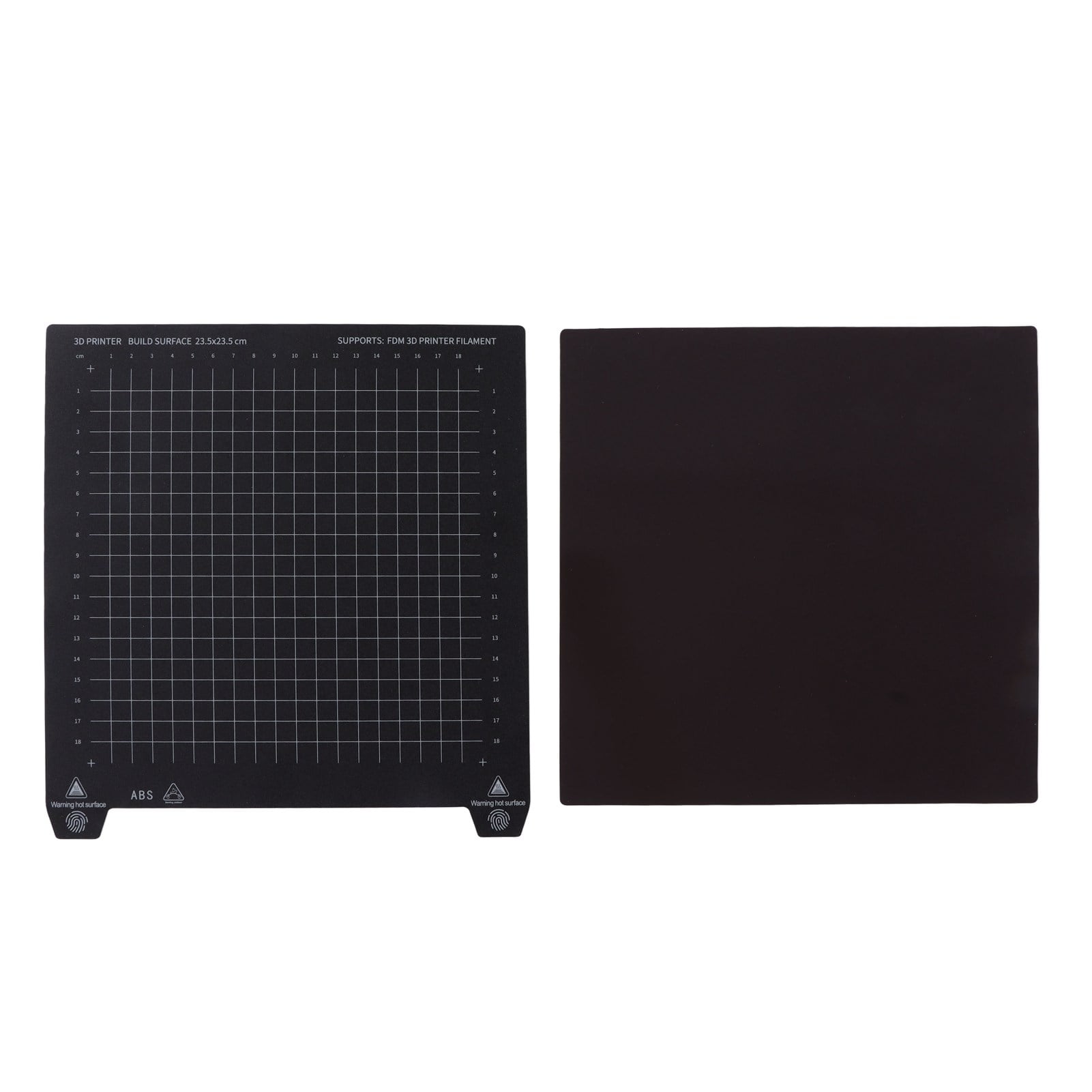

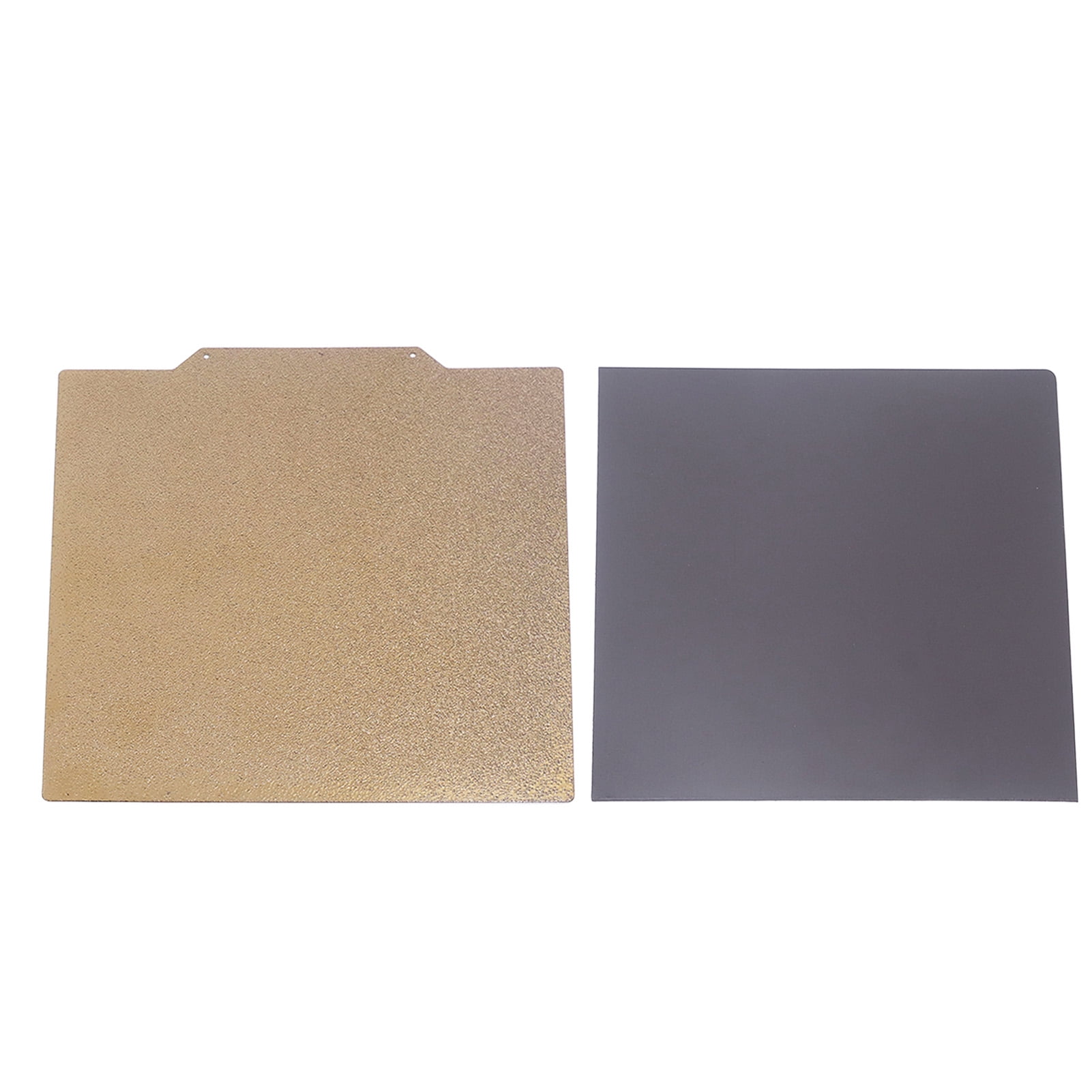

Build Plate Material For Pla - I have an ideaformer pei textured/smooth plate and no surface adhesion (both printing, or pei surface attaching to plate) printing both pla and petg with no glue. What material you use, and the frequency of use. Is mk3s the latest and the. Whether you need a glass plate for a smooth finish or a. Below you will find a guide with common build plates and information on when you should (and shouldn't) be using them. Once i figured out how to properly clean it, i've rarely had issues with adhesion with either pla, or. I tried pla on the textured sheet when i first got it and from what i remember it can work, but there were often first layer adhesion issues (i. Even taking it off when. I have been using wham bam pex build plates for the past 4 years for printing pla. I've had and ender 3 pro for around 6 months, and i use a magnetic build plate on it. Once i figured out how to properly clean it, i've rarely had issues with adhesion with either pla, or. Whether you need a glass plate for a smooth finish or a. For pla, the most commonly used value for our printers is 75° c. I've had and ender 3 pro for around 6 months, and i use a magnetic build plate on it. Never used glue or anything else to improve adhesion. I was using the makerbot tough pla with the build plate at 35 degrees. Without glue stick, the print sticks way too strongly, but with glue stick the print tends to come loose. Works perfectly with a heated bed at 50°c. I have been using wham bam pex build plates for the past 4 years for printing pla. During checkout of the mk3s, one could choose between two build plates (pei and textured power coat). I have an ideaformer pei textured/smooth plate and no surface adhesion (both printing, or pei surface attaching to plate) printing both pla and petg with no glue. Never used glue or anything else to improve adhesion. I was using the makerbot tough pla with the build plate at 35 degrees. Ensure your build plate is compatible with the materials you. Ensure your build plate is compatible with the materials you most frequently use. Glass is what comes stock on most printers. While it does a pretty. For example, pla works well on glass build plates, whereas abs is more suited for pei surfaces. I have an ideaformer pei textured/smooth plate and no surface adhesion (both printing, or pei surface attaching. I've had and ender 3 pro for around 6 months, and i use a magnetic build plate on it. What material you use, and the frequency of use. The last setting to worry about in the material tab is diameter. On the market, we have various options over different build plate types, such as glass or tempered glass plate, polypropylene. Once i figured out how to properly clean it, i've rarely had issues with adhesion with either pla, or. I tried pla on the textured sheet when i first got it and from what i remember it can work, but there were often first layer adhesion issues (i. Below you will find a guide with common build plates and information. While it does a pretty. Without glue stick, the print sticks way too strongly, but with glue stick the print tends to come loose. Smooth pei and satin have worked well for pla. Once i figured out how to properly clean it, i've rarely had issues with adhesion with either pla, or. The last setting to worry about in the. I was using the makerbot tough pla with the build plate at 35 degrees. Glass is what comes stock on most printers. Below you will find a guide with common build plates and information on when you should (and shouldn't) be using them. The diameter settings lets you specify what size filament is. For example, pla works well on glass. On the market, we have various options over different build plate types, such as glass or tempered glass plate, polypropylene sheet, smooth or textured pei sheet, pex type. I have an ideaformer pei textured/smooth plate and no surface adhesion (both printing, or pei surface attaching to plate) printing both pla and petg with no glue. Once i figured out how. Is mk3s the latest and the. Whether you need a glass plate for a smooth finish or a. Even taking it off when. I tried pla on the textured sheet when i first got it and from what i remember it can work, but there were often first layer adhesion issues (i. What material you use, and the frequency of. Once i figured out how to properly clean it, i've rarely had issues with adhesion with either pla, or. Whether you need a glass plate for a smooth finish or a. Smooth pei and satin have worked well for pla. On the market, we have various options over different build plate types, such as glass or tempered glass plate, polypropylene. On the market, we have various options over different build plate types, such as glass or tempered glass plate, polypropylene sheet, smooth or textured pei sheet, pex type. Never used glue or anything else to improve adhesion. Smooth pei and satin have worked well for pla. During checkout of the mk3s, one could choose between two build plates (pei and. For example, pla works well on glass build plates, whereas abs is more suited for pei surfaces. I have an ideaformer pei textured/smooth plate and no surface adhesion (both printing, or pei surface attaching to plate) printing both pla and petg with no glue. While it does a pretty. For pla, the most commonly used value for our printers is 75° c. Once i figured out how to properly clean it, i've rarely had issues with adhesion with either pla, or. Smooth pei and satin have worked well for pla. On the market, we have various options over different build plate types, such as glass or tempered glass plate, polypropylene sheet, smooth or textured pei sheet, pex type. Is mk3s the latest and the. Glass is what comes stock on most printers. I tried pla on the textured sheet when i first got it and from what i remember it can work, but there were often first layer adhesion issues (i. Whether you need a glass plate for a smooth finish or a. Pla, what matters most times is good adhesion, a roughed up piece of aluminum works awesome for large pla prints with huge. Works perfectly with a heated bed at 50°c. Without glue stick, the print sticks way too strongly, but with glue stick the print tends to come loose. Even taking it off when. I've had and ender 3 pro for around 6 months, and i use a magnetic build plate on it.3D Printer Build Plate 410x430MM Double Sided PEI Spring Steel Plate

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

3D Printing With PLA On A Glass Build Surface Learn Glass Blowing

PLA/ABS Build Plate (Plex3d/gekonweld) 20x20x1 Filament Shop

ABS Plastic Sheet [PlaPlate] White Scratch Build Materials

ABS Plastic Sheet [PlaPlate] White Scratch Build Materials

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

Spring Steel Build Plate 2 Sided PLA ABS Printable Flexible 3D

2024 3D Printer Build Plate 410x430MM Double Sided PEI Spring Steel

Ensure Your Build Plate Is Compatible With The Materials You Most Frequently Use.

The Last Setting To Worry About In The Material Tab Is Diameter.

I Was Using The Makerbot Tough Pla With The Build Plate At 35 Degrees.

What Material You Use, And The Frequency Of Use.

Related Post:

![ABS Plastic Sheet [PlaPlate] White Scratch Build Materials](https://www.museigenhobby.com/wp-content/uploads/2018/06/ABS-Plastic-Sheet.jpg)

![ABS Plastic Sheet [PlaPlate] White Scratch Build Materials](https://www.museigenhobby.com/wp-content/uploads/2018/06/ABS-Plastic-Sheet_02.jpg)