Building A Large 3D Printer

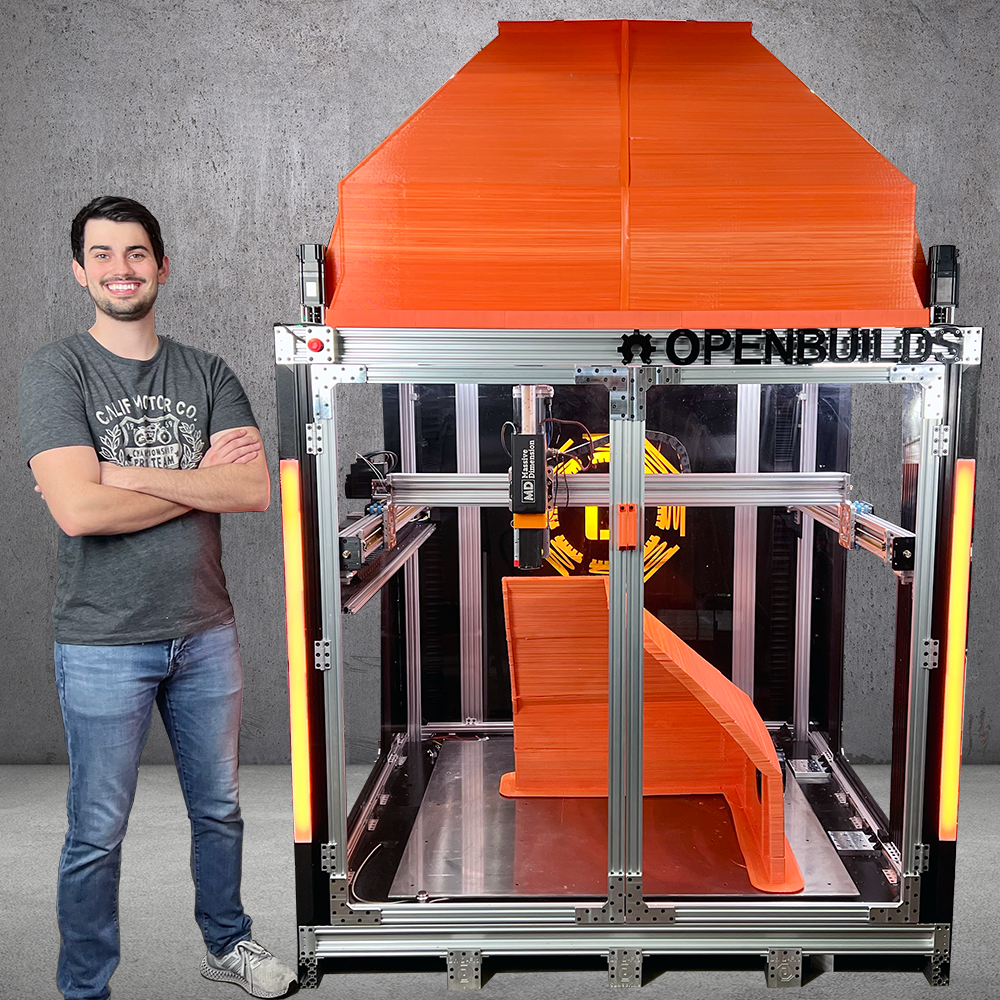

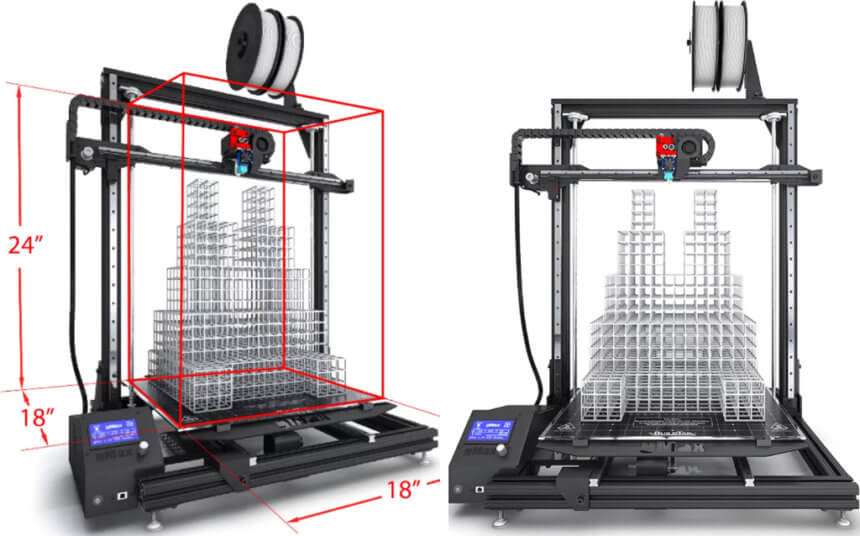

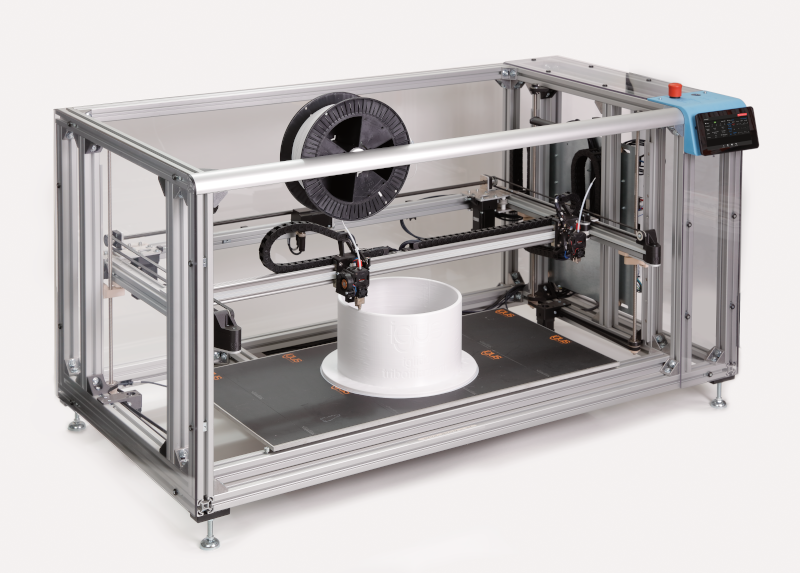

Building A Large 3D Printer - Looking to start a large format 3d printer build? With a 420x420x500mm capacity, it’s ideal for printing. In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3d printer and the sketchup file is included for you to make any changes needed. One of the methods is slicing or splitting the model in fusion 360,. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. From intricate models to functional structures. Take a look at what is possible with a large format 3d printer: Large 3d printers are part of my research explore survive (res) *working title* video game concept. Because i need to print something really big for an incoming project. Ever wanted to make a diy 3d printer bigger? From intricate models to functional structures. Because i need to print something really big for an incoming project. This is my largest build to date and as far as i. With this series, i'm gonna show you how to build a big 3d printer, but also with industrial quality components for a low price. In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3d printer and the sketchup file is included for you to make any changes needed. In this video we talk about the challenges behind making a diy. First of all, in this first episode of the series. Ever wanted to make a diy 3d printer bigger? It is listed as 200mm in each direction as default, which is rather much more than our printer can do. Looking to start a large format 3d printer build? It is used for generally for interfacing serval things like endstop switch, stepper motor driver, heatbed,. For most users, i recommend the anycubic kobra max 2 as the best balance of price, performance, and max build size. They allow the construction of base segments used in my xrea research base. Timing belt for gt2 pulley x 04 meter. First of. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. Instead, you should learn more about 3d printing large objects on a standard desktop printer build plate. Take a look at what is possible with a large format 3d printer: Large 3d printers. Timing belt for gt2 pulley x 04 meter. For most users, i recommend the anycubic kobra max 2 as the best balance of price, performance, and max build size. Looking to start a large format 3d printer build? They allow the construction of base segments used in my xrea research base. How to design and build a 3d printer: Looking to start a large format 3d printer build? They allow the construction of base segments used in my xrea research base. This is my largest build to date and as far as i. Instead, you should learn more about 3d printing large objects on a standard desktop printer build plate. Large 3d printers are part of my research explore. Because i need to print something really big for an incoming project. First of all, in this first episode of the series. Building a 3d printer from a kit is a really good starting point for newbies and pros alike. This instructable summarises the design, build, and calibration phases of creating a custom 3d printer by outlining the key design. How to design and build a 3d printer: Because i need to print something really big for an incoming project. Building a 3d printer from a kit is a really good starting point for newbies and pros alike. Instead, you should learn more about 3d printing large objects on a standard desktop printer build plate. In this episode i make. In this video we talk about the challenges behind making a diy. First of all, in this first episode of the series. Ever wanted to make a diy 3d printer bigger? Printer printing area this defines how large an area we can print on. How to design and build a 3d printer: I've built a giant 3d printer with a build volume of 1110mmx1110mmx2005mm that adds up to more than 2.5 m3 build volume. From intricate models to functional structures. First of all, in this first episode of the series. Timing belt for gt2 pulley x 04 meter. It is used for generally for interfacing serval things like endstop switch, stepper motor. Printer printing area this defines how large an area we can print on. This instructable summarises the design, build, and calibration phases of creating a custom 3d printer by outlining the key design decisions i made. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy. Welcome, to the project page of one of the largest diy 3d printers!. This is my largest build to date and as far as i. Because i need to print something really big for an incoming project. Instead, you should learn more about 3d printing large objects on a standard desktop printer build plate. Building a 3d printer from a. In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3d printer and the sketchup file is included for you to make any changes needed. Because i need to print something really big for an incoming project. Instead, you should learn more about 3d printing large objects on a standard desktop printer build plate. With a 420x420x500mm capacity, it’s ideal for printing. Timing belt for gt2 pulley x 04 meter. Welcome, to the project page of one of the largest diy 3d printers!. For most users, i recommend the anycubic kobra max 2 as the best balance of price, performance, and max build size. This instructable summarises the design, build, and calibration phases of creating a custom 3d printer by outlining the key design decisions i made. This is my largest build to date and as far as i. A lightweight, portable, accurate 3d printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. It is listed as 200mm in each direction as default, which is rather much more than our printer can do. Building a 3d printer from a kit is a really good starting point for newbies and pros alike. They allow the construction of base segments used in my xrea research base. How to design and build a 3d printer: In this episode i make the frame and mechanics of a giant 3d printer from scratch, why? First of all, in this first episode of the series.DIY Large Format 3D Printer

Just Finished my Large 3D printer build! 3Dprinting

Building My Big 3D Printer YouTube

Large 3D Printer with Build Volume Perfect for 3D Printing Big Objects

Building a Large Format 3D Printer Part 4 Printing YouTube

Free design data DIY largeformat 3D printer igus Blog

GINORMOUS 3D PRINTER BUILT FROM SCRATCH YouTube

GIANT 3D PRINTER FROM SCRATCH IT WORKS! YouTube

LARGE 3D PRINTER BUILD YouTube

Large Scale 3D Printers Builder 3D Printers

In This Video We Talk About The Challenges Behind Making A Diy.

From Intricate Models To Functional Structures.

It Is Used For Generally For Interfacing Serval Things Like Endstop Switch, Stepper Motor Driver, Heatbed,.

Ever Wanted To Make A Diy 3D Printer Bigger?

Related Post: