Building A Wiring Harness

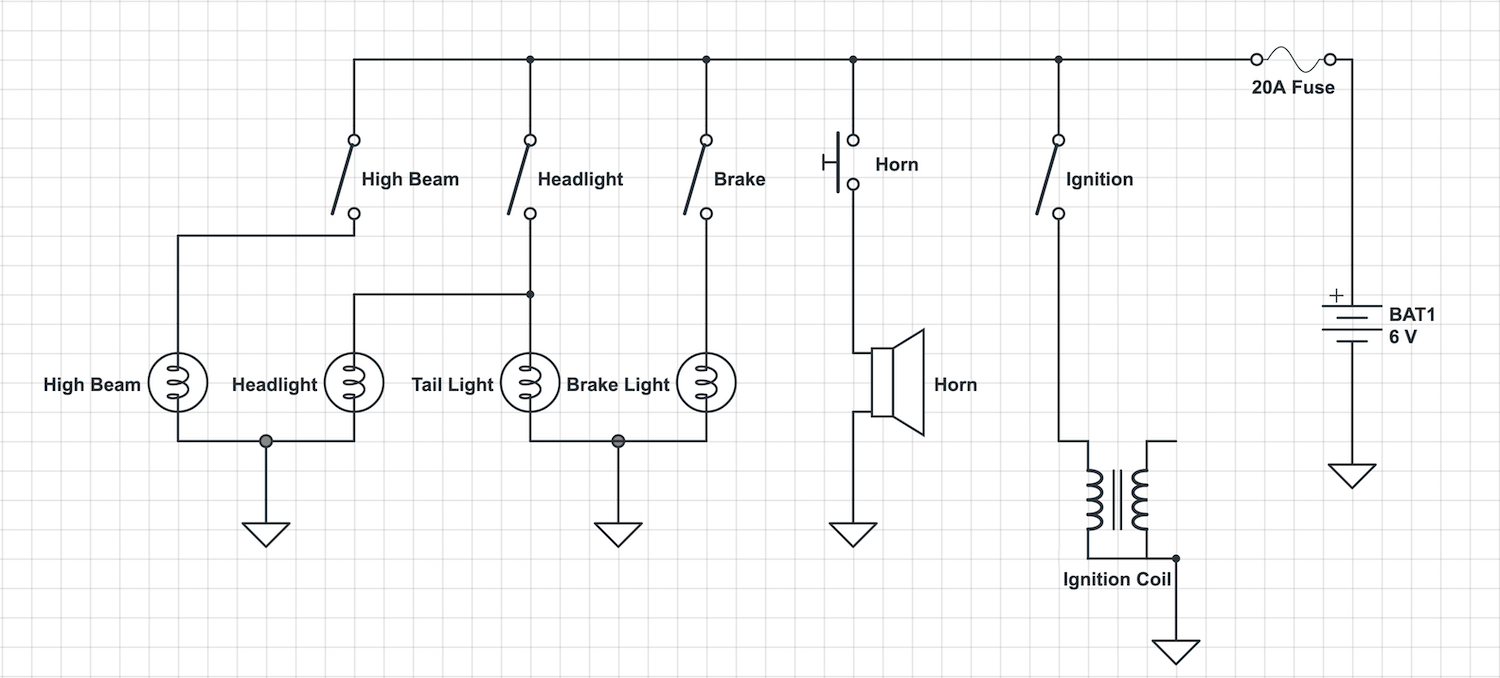

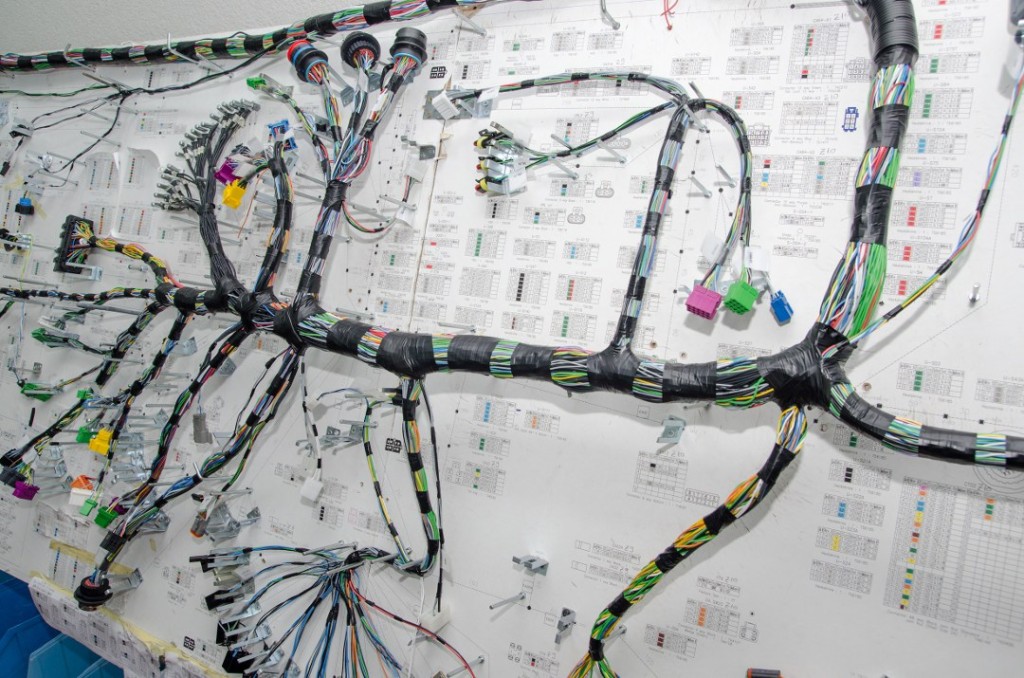

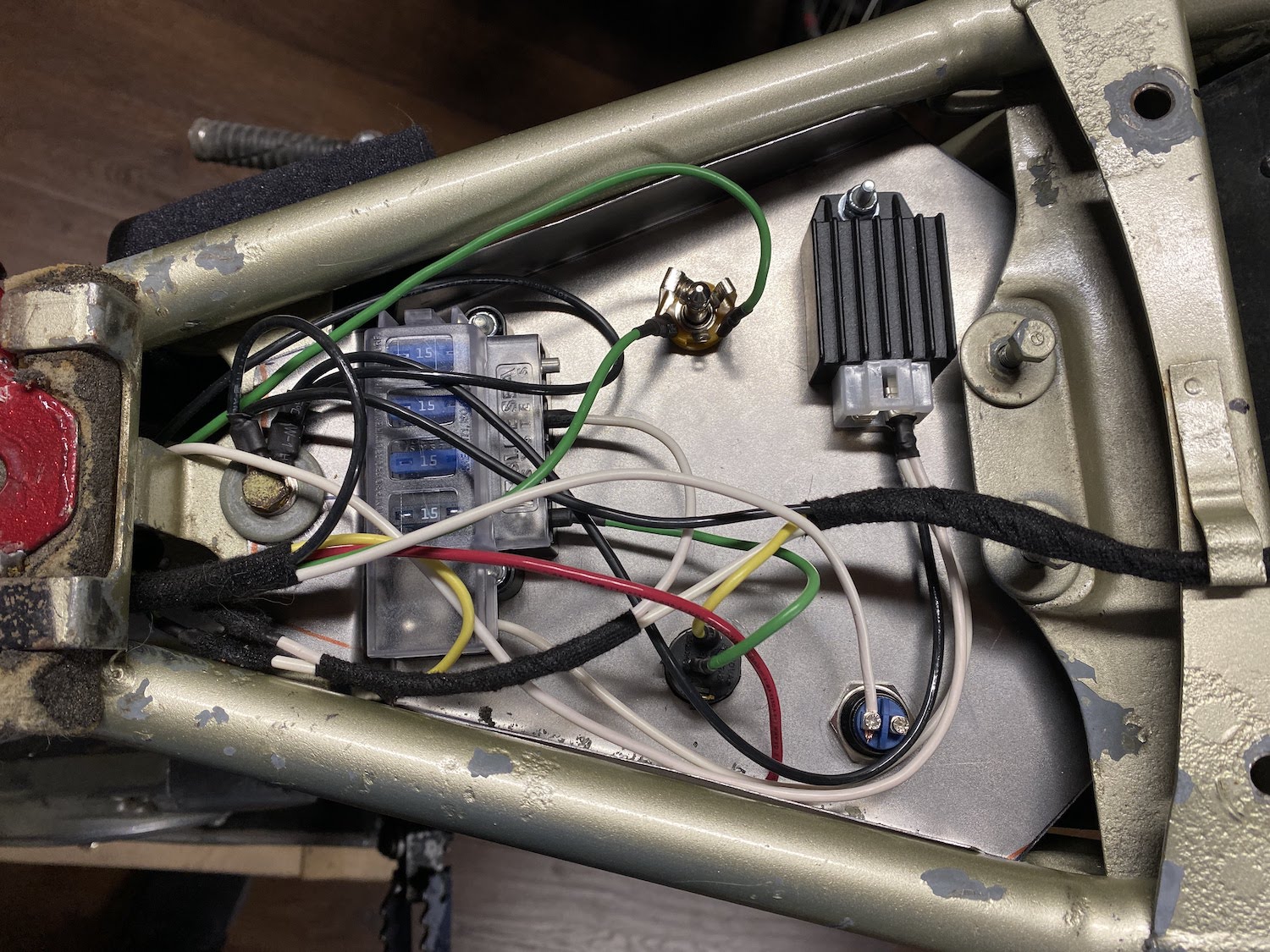

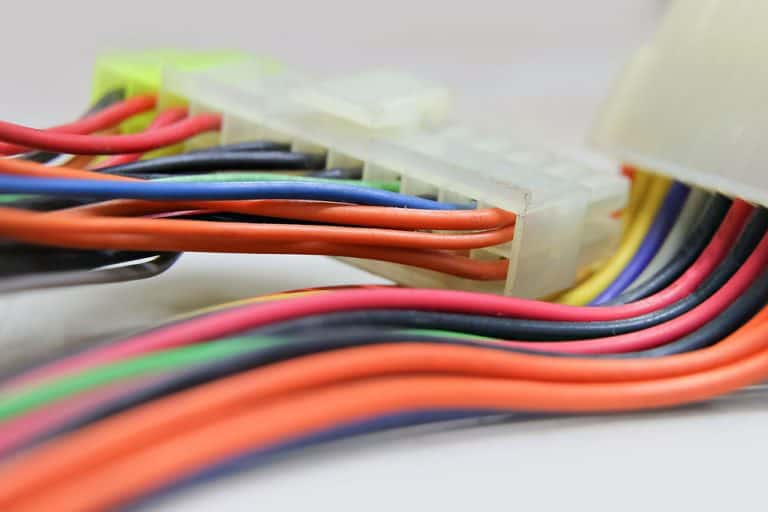

Building A Wiring Harness - Whether you’re tackling a custom build or upgrading an existing setup, this harness is built for flexibility and durability to meet the demands of your project. As tempting as it is to give up and move on to a different project (yes, we’ve been there plenty of times), building a wiring harness from scratch isn’t nearly as difficult as you may. The first thing i did was add up the total length of 10 awg and 14 awg wire that the diagram calls for. Designing and testing cable harness steps to build a wire harness. What are the best practices for wire harness design? However, building a wiring harness is not just limited to the production step alone. The following points showcase the basic requirements and steps to be taken to build a wire harness. I have built several chevy trucks. The process of wire harness assembly is intricate and requires meticulous attention to detail at every stage, from design to dispatch. Having a good plan and sticking. A system that holds together groups of electrical wires in the electrical system of a machine…. Here are some of the builds you can find on this channel. What are the best practices for wire harness design? However, building a wiring harness is not just limited to the production step alone. Here is what you need to know to make great looking wiring, whether you’re repairing a factory harness or making a new one from scratch. The following points showcase the basic requirements and steps to be taken to build a wire harness. The following list turned out to be a little. Each step is crucial in ensuring the. As tempting as it is to give up and move on to a different project (yes, we’ve been there plenty of times), building a wiring harness from scratch isn’t nearly as difficult as you may. Designing and testing cable harness steps to build a wire harness. The first thing i did was add up the total length of 10 awg and 14 awg wire that the diagram calls for. As you may expect the main part of the harness is the wires that carry the. The process of wire harness assembly is intricate and requires meticulous attention to detail at every stage, from design to dispatch.. A system that holds together groups of electrical wires in the electrical system of a machine…. However, sometimes, you need to build your. In today’s dynamic environment, mastering optimal wire harness design is not only a technical endeavor but also. We recently caught up with jeremy gibbons of indy wiring services to discuss wiring looms and what engine builders need. The following list turned out to be a little. The fundamental criteria and procedures for creating a wire harness are as below. When making your custom wiring harness, you need to have the following components: There are many different steps that are taken before we even cut the first wire. Refer to the detailed pinout below. In today’s dynamic environment, mastering optimal wire harness design is not only a technical endeavor but also. As tempting as it is to give up and move on to a different project (yes, we’ve been there plenty of times), building a wiring harness from scratch isn’t nearly as difficult as you may. Refer to the detailed pinout below. The following. However, sometimes, you need to build your. However, building a wiring harness is not just limited to the production step alone. When making your custom wiring harness, you need to have the following components: As tempting as it is to give up and move on to a different project (yes, we’ve been there plenty of times), building a wiring harness. I have built several chevy trucks. The following points showcase the basic requirements and steps to be taken to build a wire harness. A system that holds together groups of electrical wires in the electrical system of a machine…. However, sometimes, you need to build your. The method shown here is just one way to. When making your custom wiring harness, you need to have the following components: As you may expect the main part of the harness is the wires that carry the. Designing and testing cable harness steps to build a wire harness. A system that holds together groups of electrical wires in the electrical system of a machine…. Here is what you. I have built several chevy trucks. Having a good plan and sticking. We recently caught up with jeremy gibbons of indy wiring services to discuss wiring looms and what engine builders need to make better harnesses for their customers. However, building a wiring harness is not just limited to the production step alone. However, sometimes, you need to build your. The following points showcase the basic requirements and steps to be taken to build a wire harness. As you may expect the main part of the harness is the wires that carry the. The fundamental criteria and procedures for creating a wire harness are as below. There are many different steps that are taken before we even cut the first. We recently caught up with jeremy gibbons of indy wiring services to discuss wiring looms and what engine builders need to make better harnesses for their customers. Having a good plan and sticking. A system that holds together groups of electrical wires in the electrical system of a machine…. The process of wire harness assembly is intricate and requires meticulous. A system that holds together groups of electrical wires in the electrical system of a machine…. The process of wire harness assembly is intricate and requires meticulous attention to detail at every stage, from design to dispatch. We recently caught up with jeremy gibbons of indy wiring services to discuss wiring looms and what engine builders need to make better harnesses for their customers. The first thing i did was add up the total length of 10 awg and 14 awg wire that the diagram calls for. The following points showcase the basic requirements and steps to be taken to build a wire harness. As you may expect the main part of the harness is the wires that carry the. However, building a wiring harness is not just limited to the production step alone. The first was my 1964 c10 named crown spoyal and the most recent c10 truck project was the 1969. However, sometimes, you need to build your. There are many different steps that are taken before we even cut the first wire. When making your custom wiring harness, you need to have the following components: The fundamental criteria and procedures for creating a wire harness are as below. Whether you’re tackling a custom build or upgrading an existing setup, this harness is built for flexibility and durability to meet the demands of your project. What are the best practices for wire harness design? Having a good plan and sticking. As tempting as it is to give up and move on to a different project (yes, we’ve been there plenty of times), building a wiring harness from scratch isn’t nearly as difficult as you may.How to Build Your Own Wiring Harness A StepbyStep Guide

Building a wiring harness is all about patience and planning Hagerty

Building A Wiring Harness

Building a Wire Harness An ultimate guide on DIY Wire Harness Assembly

Building Your Own Wiring Harness Wiring Harness Accessory Bu

Building A Wiring Harness

optimal tour How to build a wiring harness that will last

How I failed my way to success building a wiring harness, from

Building a Wire Harness An ultimate guide on DIY Wire Harness Assembly

Build Your Own Wiring Harness Kit

The Following List Turned Out To Be A Little.

The Method Shown Here Is Just One Way To.

Here Is What You Need To Know To Make Great Looking Wiring, Whether You’re Repairing A Factory Harness Or Making A New One From Scratch.

Here Are Some Of The Builds You Can Find On This Channel.

Related Post: