Building Duct Design

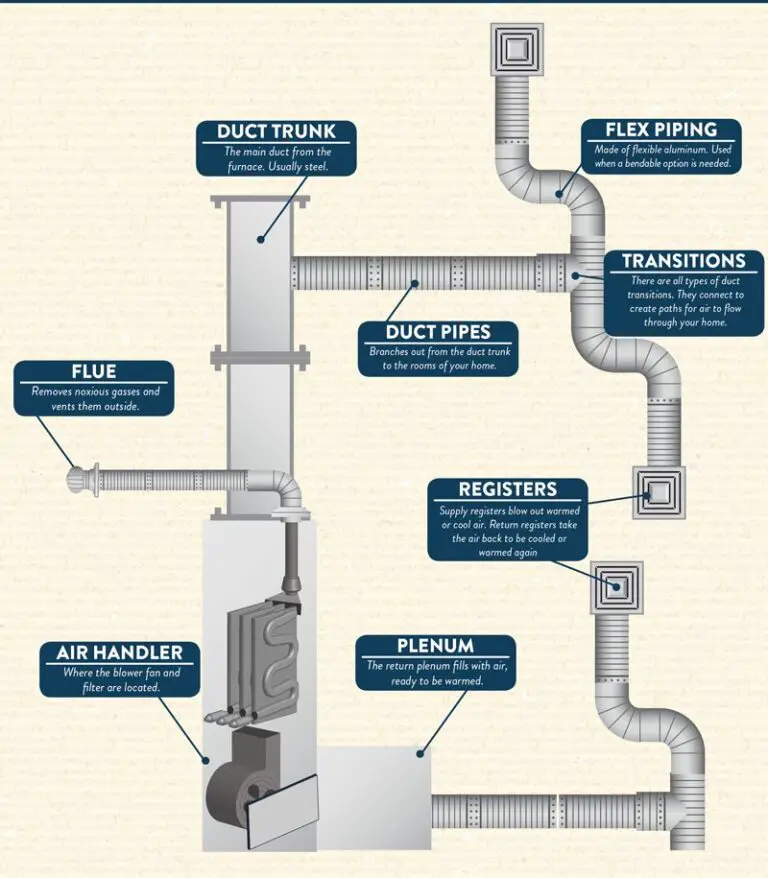

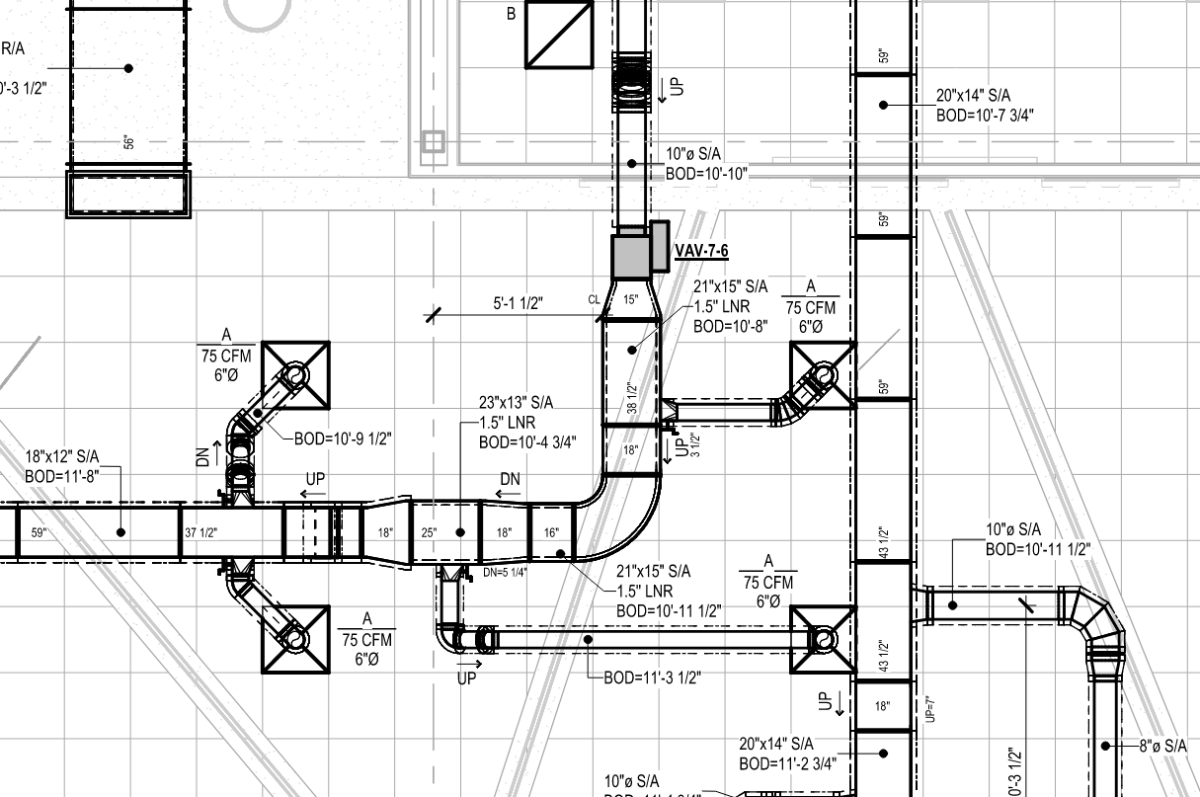

Building Duct Design - We’ll include a full worked example as well as using cfd simulations to optimise. Ductwork design involves planning and creating a system of pathways that allow heated or cooled air to travel throughout the building. Most hvac units are designed to have a 400 cfm of airflow for every 12000 btu or 1 ton of cooling capacity and 12000 btu divided by 400 cfm is 30. Some exhaust system ducts are addressed in chapter 5, such as kitchen exhaust. For the most comprehensive information on ductwork design, including technical specifications, refer to the air conditioning contractors of america’s manual q, commercial duct design. Chapter 6 addresses duct systems used in hvac systems and some exhaust systems. Most ductwork today is flexduct, wire coils inside a layer of insulation and sealed with a metallic covering. Explore the essential functions, types, and design considerations of ducts in building systems for efficient airflow management. It includes determining the layout, size, and materials of. Other issues include space restrictions, noise level, capacity for expansion,. It includes determining the layout, size, and materials of. Number one is the heating and cooling load calculation using a protocol like acca’s. Ducts are essential in modern construction. Why it is important to properly design and install high quality, efficient ducted air systems ? So, identify the btu needed for each room and divide it by 30 to get the required cfm for the respective room. Proper ductwork design ensures efficient airflow distribution, optimal hvac performance, and a comfortable indoor environment. We’ll include a full worked example as well as using cfd simulations to optimise. Explore the essential functions, types, and design considerations of ducts in building systems for efficient airflow management. With the total heat load/gain, the designer will be able to select the exact furnace, ac/heat pump, and evaporator coil necessary to meet the home’s heating and cooling loads. Designing a duct system is important but there are a few critical steps that come first. Used in commercial buildings to maximize space utilization in limited areas. It includes determining the layout, size, and materials of. Ducts channel cooled/heated air from central air handlers to. Explore the essential functions, types, and design considerations of ducts in building systems for efficient airflow management. So, identify the btu needed for each room and divide it by 30 to. Why it is important to properly design and install high quality, efficient ducted air systems ? Other issues include space restrictions, noise level, capacity for expansion,. Ductwork design involves planning and creating a system of pathways that allow heated or cooled air to travel throughout the building. Consider factors like airflow calculation,. It includes determining the layout, size, and materials. So, identify the btu needed for each room and divide it by 30 to get the required cfm for the respective room. In this article we’ll be learning how to size and design a ductwork system for efficiency. Rarely available studio at the grand ohio, one of only 15 unique lofts in the building that share private elevator access, soaring. Ducts channel cooled/heated air from central air handlers to. Other issues include space restrictions, noise level, capacity for expansion,. With the total heat load/gain, the designer will be able to select the exact furnace, ac/heat pump, and evaporator coil necessary to meet the home’s heating and cooling loads. It can be installed in walls, ceilings, attics or under floors in.. Most hvac units are designed to have a 400 cfm of airflow for every 12000 btu or 1 ton of cooling capacity and 12000 btu divided by 400 cfm is 30. It includes determining the layout, size, and materials of. In this article we’ll be learning how to size and design a ductwork system for efficiency. Used in commercial buildings. Ductwork should be planned out by professionals who use design systems and math to produce an efficient hvac central air duct system. It includes determining the layout, size, and materials of. Ducts channel cooled/heated air from central air handlers to. Consider factors like airflow calculation,. Most ductwork today is flexduct, wire coils inside a layer of insulation and sealed with. Larger ducts require a larger initial investment, but result in lower fan energy costs over the life of the system. Ductwork design involves planning and creating a system of pathways that allow heated or cooled air to travel throughout the building. So, identify the btu needed for each room and divide it by 30 to get the required cfm for. Used in commercial buildings to maximize space utilization in limited areas. It includes determining the layout, size, and materials of. Some exhaust system ducts are addressed in chapter 5, such as kitchen exhaust. In this article we’ll be learning how to size and design a ductwork system for efficiency. Why it is important to properly design and install high quality,. Most hvac units are designed to have a 400 cfm of airflow for every 12000 btu or 1 ton of cooling capacity and 12000 btu divided by 400 cfm is 30. Early consideration of the hvac system in an integrated design allows the designer to allocate adequate space for the equipment and ducts while identifying principal potential conflicts. It includes. Designing a duct system is important but there are a few critical steps that come first. Most ductwork today is flexduct, wire coils inside a layer of insulation and sealed with a metallic covering. Ducts channel cooled/heated air from central air handlers to. Consider factors like airflow calculation,. So, identify the btu needed for each room and divide it by. Used in commercial buildings to maximize space utilization in limited areas. Ducts are essential in modern construction. Ductwork should be planned out by professionals who use design systems and math to produce an efficient hvac central air duct system. Early consideration of the hvac system in an integrated design allows the designer to allocate adequate space for the equipment and ducts while identifying principal potential conflicts. Ducts channel cooled/heated air from central air handlers to. For the most comprehensive information on ductwork design, including technical specifications, refer to the air conditioning contractors of america’s manual q, commercial duct design. Proper ductwork design ensures efficient airflow distribution, optimal hvac performance, and a comfortable indoor environment. Number one is the heating and cooling load calculation using a protocol like acca’s. Consider factors like airflow calculation,. Larger ducts require a larger initial investment, but result in lower fan energy costs over the life of the system. With the total heat load/gain, the designer will be able to select the exact furnace, ac/heat pump, and evaporator coil necessary to meet the home’s heating and cooling loads. So, identify the btu needed for each room and divide it by 30 to get the required cfm for the respective room. Ductwork design involves planning and creating a system of pathways that allow heated or cooled air to travel throughout the building. Hvac ductwork refers to the network of air passages or ducts that connect hvac equipment to interior spaces. Rarely available studio at the grand ohio, one of only 15 unique lofts in the building that share private elevator access, soaring ceiling heights, private terraces, central heat and. Chapter 6 addresses duct systems used in hvac systems and some exhaust systems.Ductwork Components for Commercial Buildings Engineering Intro

Designing Hvac Ducts For Residential

Design Practices for Building and Modifying Duct Systems ACHR News

HVAC Duct Fabrication drawings Revit MEP AutoCAD Forums

Designing Hvac Ducts For Residential

Quality Control for Ductwork JLC Online HVAC, Building Performance

Basic Residential Ductwork Design

HVAC stands for heating, ventilation, air conditioning and cooling. A

Residential Duct Design Guide

Residential Air Duct Design

We’ll Include A Full Worked Example As Well As Using Cfd Simulations To Optimise.

Why It Is Important To Properly Design And Install High Quality, Efficient Ducted Air Systems ?

Most Hvac Units Are Designed To Have A 400 Cfm Of Airflow For Every 12000 Btu Or 1 Ton Of Cooling Capacity And 12000 Btu Divided By 400 Cfm Is 30.

It Includes Determining The Layout, Size, And Materials Of.

Related Post: