Building Laser

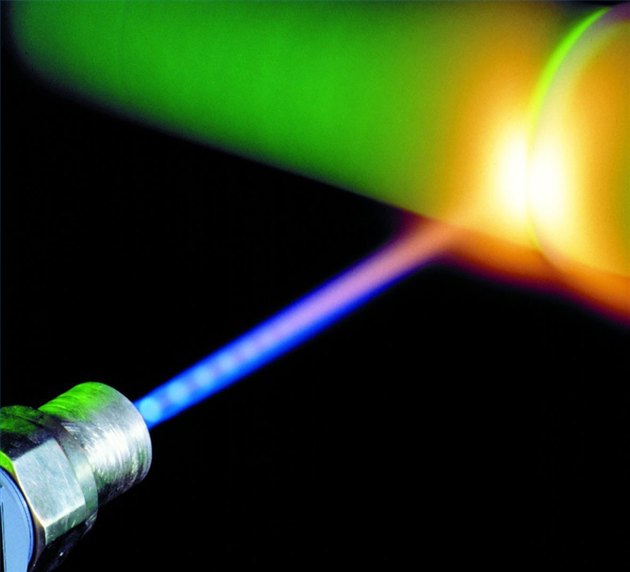

Building Laser - Construction professionals prize these tools for their versatility and precision, whether working indoors or out in the field. Want to learn how to build a simple but powerful laser with electronics you already have in your house? (this process was first proposed in 1917 by albert einstein.) I set the goal to make nice all in one machine, that performs well and also looks good. Either to get a dvd drive for pc and extract only the diode assembly (aka sled). You can get old dvd rw drives on ebay for >15usd, or just look around and ask friends if they don't have some old unused drives. Today, lasers are used for purposes ranging from measurement to reading encoded data, and there are several ways to make a laser, depending on your budget and skills. It's incredibly simple.or is it? In this article, we will walk you through the process of building your own powerful laser, ensuring safety and precision every step of the way. The 1st step is the motion control system. In this article, we will walk you through the process of building your own powerful laser, ensuring safety and precision every step of the way. Line laser applications and benefits. This is one of my favorite diy laser projects out there, as it makes use of old pa. Thankfully you can build a very effective enclosure for as little as $40 in materials (not including exhaust fan, but even these can be had for cheap). Their extended level lines prove invaluable across numerous tasks: Unlike traditional bubble levels, laser levels project a beam of light that serves as a reference point for various. Want to learn how to build a simple but powerful laser with electronics you already have in your house? Laser levels offer precision, reliability, and a measure of safety. Today, lasers are used for purposes ranging from measurement to reading encoded data, and there are several ways to make a laser, depending on your budget and skills. I set the goal to make nice all in one machine, that performs well and also looks good. Despite being able to cut wood, paper, and a bunch of other everyday materials, a carbon dioxide laser is actually surprisingly simple. Their extended level lines prove invaluable across numerous tasks: The digifab shop is operated by student staff. In this article, we will provide you with a roundup of 13 different diy laser cutter and engraver projects that you. All you need to do is fill a tube with co2, put some. Have the cushing team scan your space with the trimble 3d laser scanner for efficient planning, design, and renovations. An inside look at the people, precision and passion that goes into the making of a laser at the laserperformance factory in banbury, uk. The 1st step is. Site visit to final scans, let's work together. Thankfully you can build a very effective enclosure for as little as $40 in materials (not including exhaust fan, but even these can be had for cheap). Here you will find a short video tour of the digifab shop. All you need to do is fill a tube with co2, put some.. Thankfully you can build a very effective enclosure for as little as $40 in materials (not including exhaust fan, but even these can be had for cheap). Unlike traditional bubble levels, laser levels project a beam of light that serves as a reference point for various. With the general diy idea framework and plan, let's start the 8 steps for. Despite being able to cut wood, paper, and a bunch of other everyday materials, a carbon dioxide laser is actually surprisingly simple. All you need to do is fill a tube with co2, put some. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to. Today, lasers are used for purposes ranging from measurement to reading encoded data, and there are several ways to make a laser, depending on your budget and skills. Provide a source of energy. With the general diy idea framework and plan, let's start the 8 steps for building a laser cutter. Despite how exotic they appear, there's one you can. Their extended level lines prove invaluable across numerous tasks: Diy laser cutters can be unassembled kits that you order online and then put together yourself, or they can be built completely from scratch by sourcing each individual part separately. Lasers work, or “lase,” by stimulating electrons to emit light of a particular wavelength. In this article, we will provide you. Line laser applications and benefits. It's incredibly simple.or is it? Lasers work, or “lase,” by stimulating electrons to emit light of a particular wavelength. Or buy just the laser assembly from the internet. The 1st step is the motion control system. Gprs 3d laser scanning services quickly and accurately document buildings and infrastructure with leica laser scanners to deliver lidar point clouds, 2d cad drawings, and 3d bim models that expedite project planning and execution. Diy laser cutters can be unassembled kits that you order online and then put together yourself, or they can be built completely from scratch by sourcing. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3d printed. I set the goal to make nice all in one machine, that performs well and also looks good. All you need to do is fill a tube with co2, put some. These. Their extended level lines prove invaluable across numerous tasks: The digifab shop is operated by student staff. I will elaborate on the specific making process and the details involved. Construction professionals prize these tools for their versatility and precision, whether working indoors or out in the field. An inside look at the people, precision and passion that goes into the making of a laser at the laserperformance factory in banbury, uk. Inside buildings, line lasers truly shine. Visit us today for personalized treatments in a relaxing, professional environment. What tools do i need? Despite how exotic they appear, there's one you can build with ordinary supplies. Thankfully you can build a very effective enclosure for as little as $40 in materials (not including exhaust fan, but even these can be had for cheap). I set the goal to make nice all in one machine, that performs well and also looks good. Have the cushing team scan your space with the trimble 3d laser scanner for efficient planning, design, and renovations. Provide a source of energy. After long research on the components that are available on ali express, i decided to use well known open builds acro platform and popular endurance 10w laser. Diy laser cutters can be unassembled kits that you order online and then put together yourself, or they can be built completely from scratch by sourcing each individual part separately. This is one of my favorite diy laser projects out there, as it makes use of old pa.Buy Construction Lasers & Building Lasers RedBack Lasers

LiDAR Scanning 3D Laser Scanning Services iSCANO

How To Use Cross Line Laser Level Storables

How to Build a Laser Hunker

Laser Technology in the Construction Industry Construction Monitor

360 Electronic Self Leveling Rotary Green Medidor Laser Level Digital 5

The Use Of 3D Laser Scanning In Home Building And Renovations Emlii

Buy Construction Lasers & Building Lasers RedBack Lasers

3 Key Benefits of 3D Laser Scanning UK Construction Online

Buy Construction Lasers & Building Lasers RedBack Lasers

It's Incredibly Simple.or Is It?

All You Need To Do Is Fill A Tube With Co2, Put Some.

Here You Will Find A Short Video Tour Of The Digifab Shop.

(This Process Was First Proposed In 1917 By Albert Einstein.)

Related Post: