Building Must Have A Loading Dock What Is Loading Dock

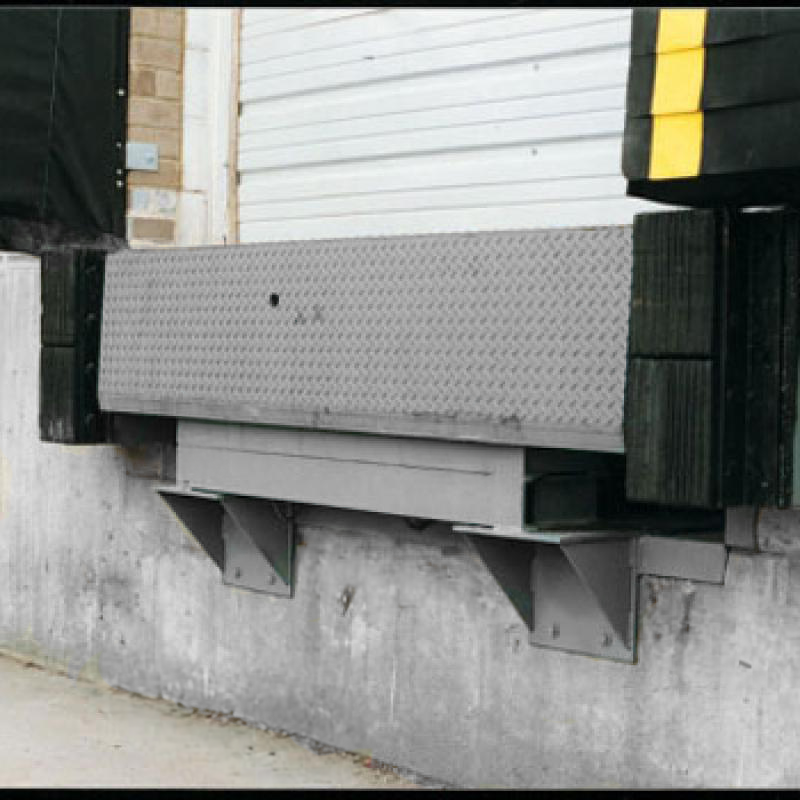

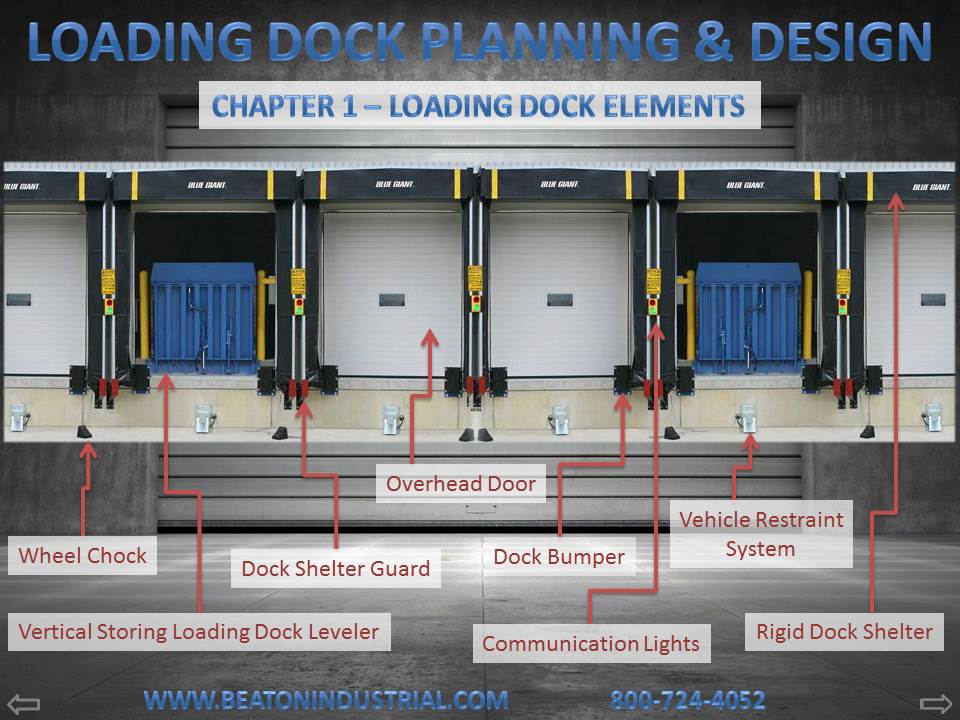

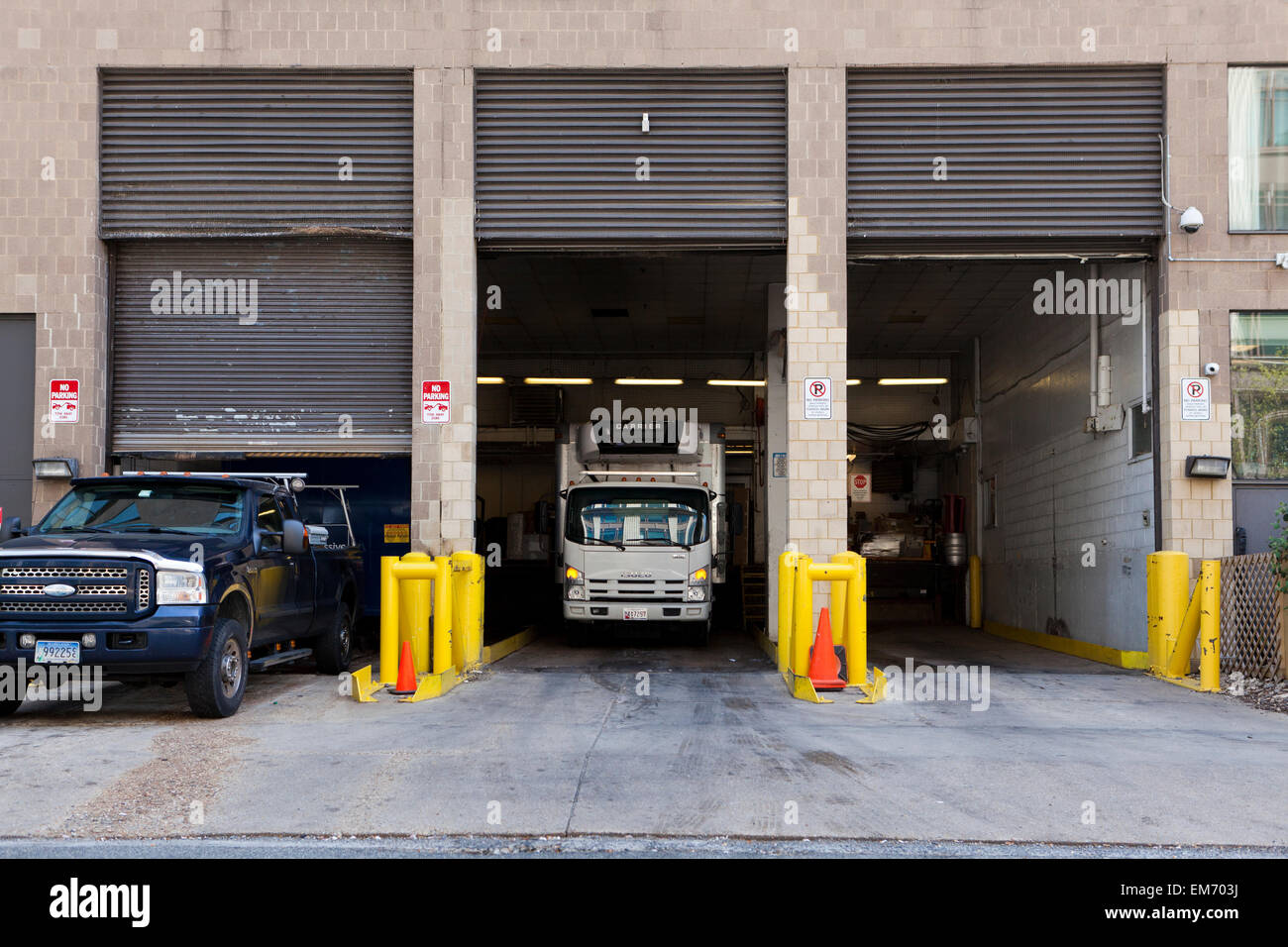

Building Must Have A Loading Dock What Is Loading Dock - Loading docks are the arrival and departure point for large shipments brought to or taken from a building by trucks and vans. A loading dock is a designated platform within a warehouse or facility that enables the efficient transfer of goods between vehicles and the. The four most critical and universal considerations you must pay careful attention to — regardless if your facility is large or small — are centerlines, apron space, dock height,. They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. In this guide, we’ll explore the essential aspects to consider when embarking on a loading dock installation journey, covering the basics of loading docks, the standard height,. There is no exact ‘rule of thumb’ in deciding how many loading docks a facility needs; The loading dock is typically the busiest spot in your building, with forklifts, pallet jacks, and pedestrians navigating simultaneously. To achieve a proper dock height for truck loading/unloading operations, the approach to the dock needs to be built incorporating a decline to the building. Here are 8 questions you should ask when planning a new loading dock. Many employers require that dock. From selecting the right types of loading docks to installing the most suitable dock. There is no exact ‘rule of thumb’ in deciding how many loading docks a facility needs; On every loading dock, crews need room to maneuver, drop products, and prepare shipments. Here are 8 questions you should ask when planning a new loading dock. Once you identify the right dock design and features, you can use this guide to build it. They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. Loading docks are attached to the exterior of manufacturing and industrial facilities. As a facility owner or manager, it is essential to know and implement osha’s requirements. What is a loading dock? So, a loading dock needs to be just as big in. Follow the best practices for building a loading dock to enhance operational efficiency. There is no exact ‘rule of thumb’ in deciding how many loading docks a facility needs; From selecting the right types of loading docks to installing the most suitable dock. They are used for the delivery and unloading of raw goods as well as the loading and. Efficiency is vital for business success. From selecting the right types of loading docks to installing the most suitable dock. So, a loading dock needs to be just as big in. What is a loading dock? They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. The loading dock space type described here includes a shipping. A loading dock is a designated platform within a warehouse or facility that enables the efficient transfer of goods between vehicles and the. Here is a list of things you should consider when designing your loading dock area so it is safe and efficient: Many employers require that dock. So,. Loading docks are attached to the exterior of manufacturing and industrial facilities. In order to understand more about loading docks, there has to be an understanding of the various parts, components and types of loading docks. They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. To achieve a. In this guide, we’ll explore the essential aspects to consider when embarking on a loading dock installation journey, covering the basics of loading docks, the standard height,. Loading docks are attached to the exterior of manufacturing and industrial facilities. Here are 8 questions you should ask when planning a new loading dock. Efficiency is vital for business success. There is. What is a loading dock? The loading dock space type described here includes a shipping. Here are 8 questions you should ask when planning a new loading dock. On every loading dock, crews need room to maneuver, drop products, and prepare shipments. In this guide, we’ll explore the essential aspects to consider when embarking on a loading dock installation journey,. Designing one properly is important for the efficient flow of materials in and out of a building. There is no exact ‘rule of thumb’ in deciding how many loading docks a facility needs; They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. The loading dock space type described. Efficiency is vital for business success. Once you identify the right dock design and features, you can use this guide to build it. In order to understand more about loading docks, there has to be an understanding of the various parts, components and types of loading docks. The loading dock is typically the busiest spot in your building, with forklifts,. In order to understand more about loading docks, there has to be an understanding of the various parts, components and types of loading docks. To achieve a proper dock height for truck loading/unloading operations, the approach to the dock needs to be built incorporating a decline to the building. The four most critical and universal considerations you must pay careful. There is no exact ‘rule of thumb’ in deciding how many loading docks a facility needs; As a facility owner or manager, it is essential to know and implement osha’s requirements. They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. The four most critical and universal considerations you. Here is a list of things you should consider when designing your loading dock area so it is safe and efficient: Once you identify the right dock design and features, you can use this guide to build it. Loading docks are the arrival and departure point for large shipments brought to or taken from a building by trucks and vans. Follow the best practices for building a loading dock to enhance operational efficiency. In order to understand more about loading docks, there has to be an understanding of the various parts, components and types of loading docks. In this guide, we’ll explore the essential aspects to consider when embarking on a loading dock installation journey, covering the basics of loading docks, the standard height,. To achieve a proper dock height for truck loading/unloading operations, the approach to the dock needs to be built incorporating a decline to the building. Here are 8 questions you should ask when planning a new loading dock. They are used for the delivery and unloading of raw goods as well as the loading and shipping of finished products. A loading dock is a designated platform within a warehouse or facility that enables the efficient transfer of goods between vehicles and the. Designing one properly is important for the efficient flow of materials in and out of a building. On every loading dock, crews need room to maneuver, drop products, and prepare shipments. From selecting the right types of loading docks to installing the most suitable dock. The loading dock is typically the busiest spot in your building, with forklifts, pallet jacks, and pedestrians navigating simultaneously. Many employers require that dock. So, a loading dock needs to be just as big in.Types of Loading Docks (2023)

Free Yourself (And Your Docks) From the Constraints of Permanent

Warehouse and Manufacturing Architectural Projects Loading Docks

What are the different types of Loading Docks?

Loading Dock Planning & Design Ebook! How to Build a dock

Loading Docks BEST Equipment & Welding

Loading Docks Dock Levelers Pit Levelers Dock Seals — Yoder

Loading Docks Ralph Moyle

Loading dock of building USA Stock Photo Alamy

Warehouse and Manufacturing Architectural Projects Loading Docks

What Is A Loading Dock?

The Four Most Critical And Universal Considerations You Must Pay Careful Attention To — Regardless If Your Facility Is Large Or Small — Are Centerlines, Apron Space, Dock Height,.

Loading Docks Are Attached To The Exterior Of Manufacturing And Industrial Facilities.

There Is No Exact ‘Rule Of Thumb’ In Deciding How Many Loading Docks A Facility Needs;

Related Post: