Building Plc Control Panel

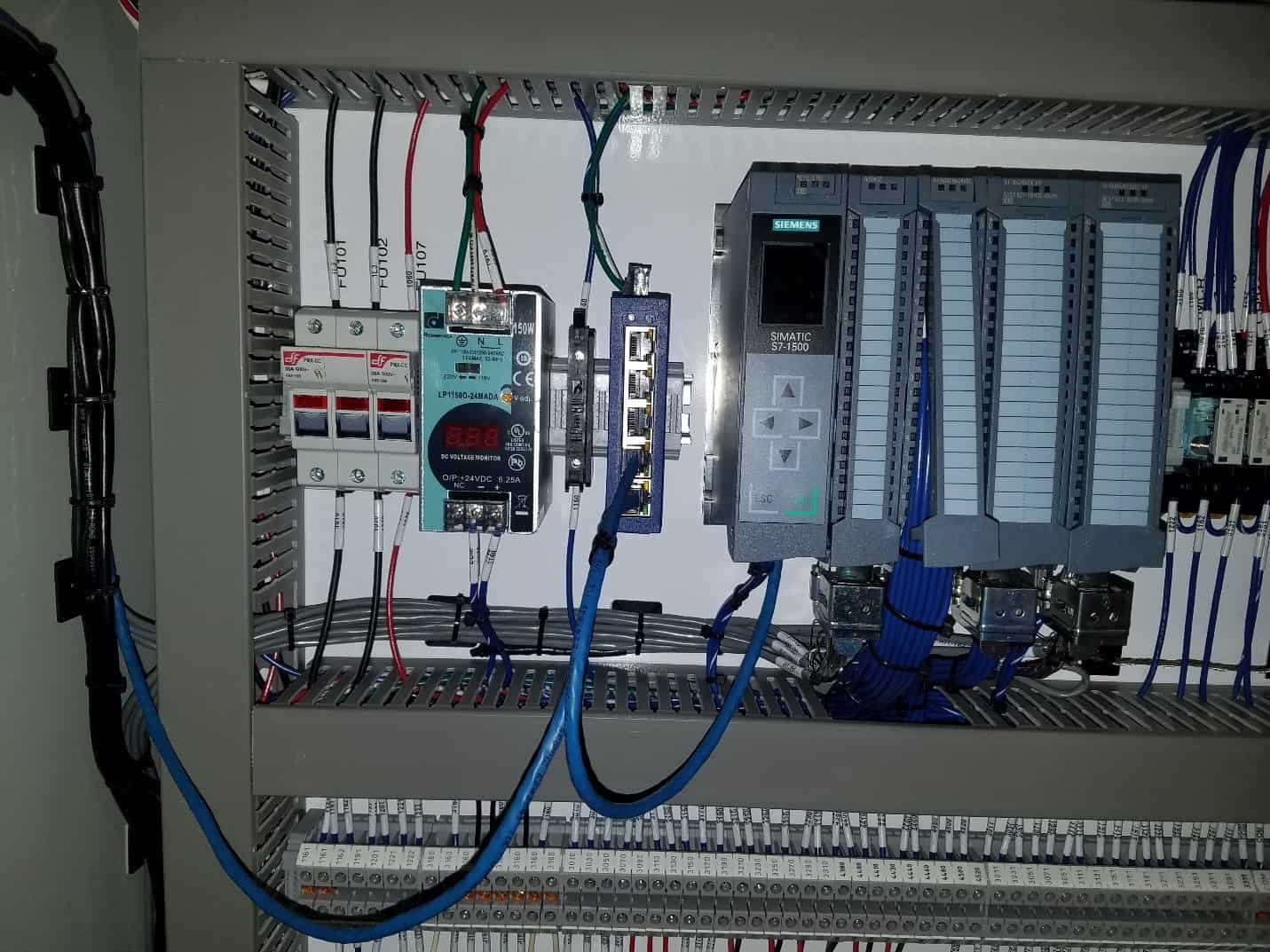

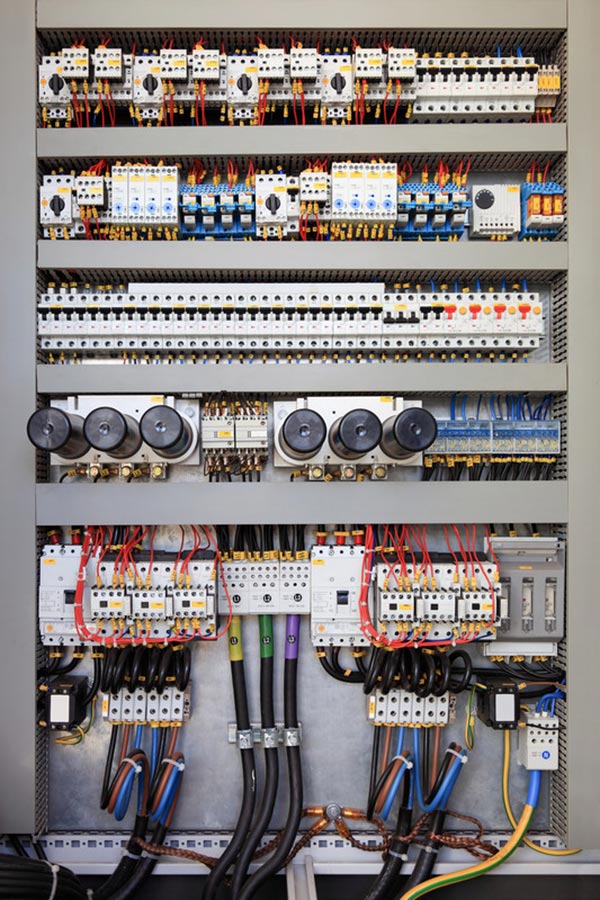

Building Plc Control Panel - The first step for increasing productivity for control panel building operations is to understand how costs are allocated to design, engineering, material, assembly,. I would like to build a control panel to house a some controls for a small system at work. I have read some of the posts with control panel building tips but i wanted to know of any tips on bundling the wires to. Does anyone know of any books or websites that can help me in building control panels. The goal is to produce a panel that is logically arranged and easy to. Designing a plc control panel involves understanding system requirements, selecting the right components, planning layouts, ensuring safety, and thorough testing. A control system of a plc panel will normally use ac and dc power at different voltage levels. Discover how much you know about plc control panels through our guide on panel layout, wiring practices, and system integration in automation. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. Probably will install small plc and couple contactors for motor controls, drive, etc. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. In the world of industrial automation, plc. An application example regarding how to correctly size and select the components that comprise a programmable logic controller (plc) panel. In this article, you’ll find a rundown of the different types of plc cabinets, tips on layout and wiring, and an exploration of the key components within these cabinets. To design a plc control panel, start by understanding the requirements of the process or machinery it will control. This article summarizes what this author believes are some best practice when it comes to control panel layout and wiring. Designing a plc control panel involves understanding system requirements, selecting the right components, planning layouts, ensuring safety, and thorough testing. Why are terminal blocks used in plc control. Identify the number of inputs and outputs, select a suitable plc, and. The first step for increasing productivity for control panel building operations is to understand how costs are allocated to design, engineering, material, assembly,. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. First, start with your local electrical codes. I have read some of the posts with control panel building tips but i wanted to know of any tips on bundling the wires to.. Why are terminal blocks used in plc control. In this article, you’ll find a rundown of the different types of plc cabinets, tips on layout and wiring, and an exploration of the key components within these cabinets. Control cabinets are often supplied with single phase ac at 220/440/550v, or. Does anyone know of any books or websites that can help. A control system of a plc panel will normally use ac and dc power at different voltage levels. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. I would like to build a control panel to house a some controls for. Designing a plc control panel involves understanding system requirements, selecting the right components, planning layouts, ensuring safety, and thorough testing. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. Control cabinets are often supplied with single phase ac at 220/440/550v, or.. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. This guide explains the steps for engineers and technicians to create important. In this video, you will learn how to build a plc panel from scratch to replace an old industrial machine.. This guide explains the steps for engineers and technicians to create important. In this article, you’ll find a rundown of the different types of plc cabinets, tips on layout and wiring, and an exploration of the key components within these cabinets. Discover how much you know about plc control panels through our guide on panel layout, wiring practices, and system. Then look at (recent) panels that others. In this video, you will learn how to build a plc panel from scratch to replace an old industrial machine. Discover how much you know about plc control panels through our guide on panel layout, wiring practices, and system integration in automation. Identify the number of inputs and outputs, select a suitable plc,. Does anyone know of any books or websites that can help me in building control panels. Control cabinets are often supplied with single phase ac at 220/440/550v, or. To design a plc control panel, start by understanding the requirements of the process or machinery it will control. The first step for increasing productivity for control panel building operations is to. The first step for increasing productivity for control panel building operations is to understand how costs are allocated to design, engineering, material, assembly,. In this video, you will learn how to build a plc panel from scratch to replace an old industrial machine. Discover how much you know about plc control panels through our guide on panel layout, wiring practices,. I have read some of the posts with control panel building tips but i wanted to know of any tips on bundling the wires to. Identify the number of inputs and outputs, select a suitable plc, and. To design a plc control panel, start by understanding the requirements of the process or machinery it will control. Designing a plc control. This guide explains the steps for engineers and technicians to create important. I would like to build a control panel to house a some controls for a small system at work. First, start with your local electrical codes. The first step for increasing productivity for control panel building operations is to understand how costs are allocated to design, engineering, material, assembly,. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency. Identify the number of inputs and outputs, select a suitable plc, and. In the world of industrial automation, plc. I am about to build my first small control panel at my job. Then look at (recent) panels that others. An application example regarding how to correctly size and select the components that comprise a programmable logic controller (plc) panel. To design a plc control panel, start by understanding the requirements of the process or machinery it will control. Probably will install small plc and couple contactors for motor controls, drive, etc. Control cabinets are often supplied with single phase ac at 220/440/550v, or. I have read some of the posts with control panel building tips but i wanted to know of any tips on bundling the wires to. A control system of a plc panel will normally use ac and dc power at different voltage levels. In this video, you will learn how to build a plc panel from scratch to replace an old industrial machine.Building Automation PLC Control Panel at Rs 1000 R.S.Puram

Control Panel Building for Industrial Automation Ontario, Michigan

Building a PLC Panel from Scratch Industrial Control Panel YouTube

Solutions Sander Mechanical Service

PLC Systems and Panel Building Wichita KS Decker Electric

PLC Control Panels Agape Water Solutions Design & Build

PLC Systems and Panel Building Wichita KS Decker Electric

Building Automation Control Box

Panel Building Vector Automation Technologies, Inc.

Control Panel Building for Industrial Automation Ontario, Michigan

Does Anyone Know Of Any Books Or Websites That Can Help Me In Building Control Panels.

Why Are Terminal Blocks Used In Plc Control.

This Article Summarizes What This Author Believes Are Some Best Practice When It Comes To Control Panel Layout And Wiring.

Designing A Plc Control Panel Involves Understanding System Requirements, Selecting The Right Components, Planning Layouts, Ensuring Safety, And Thorough Testing.

Related Post: