Cable Bracing For Metal Building

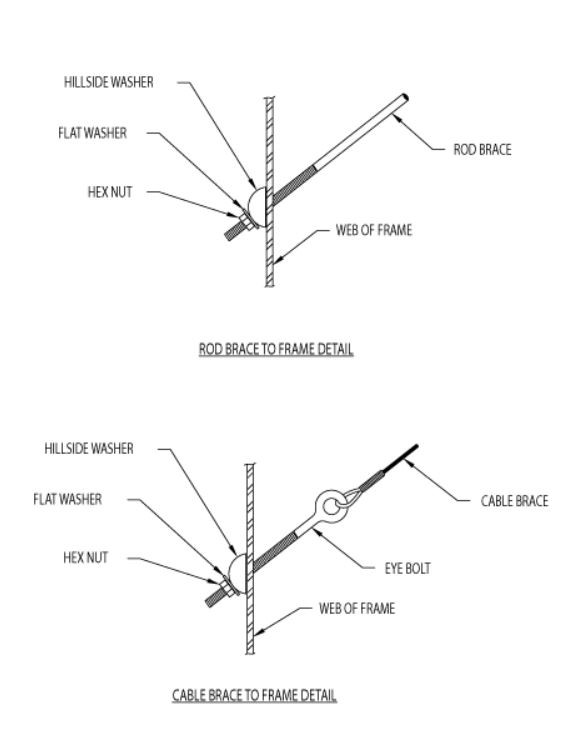

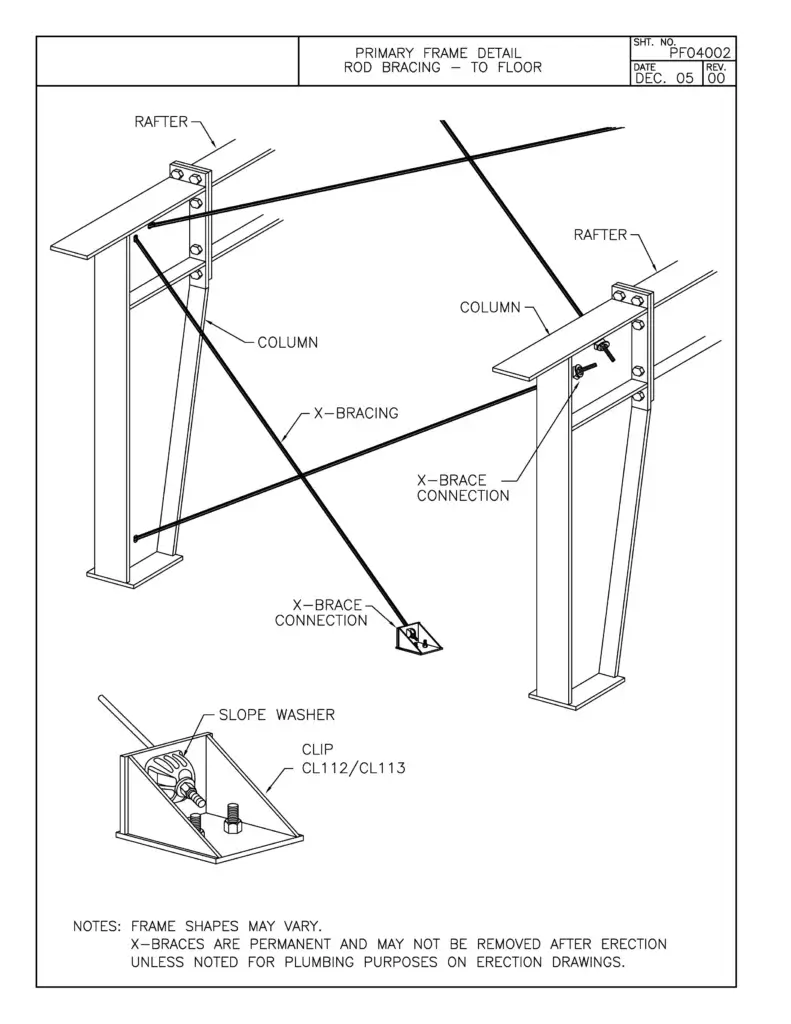

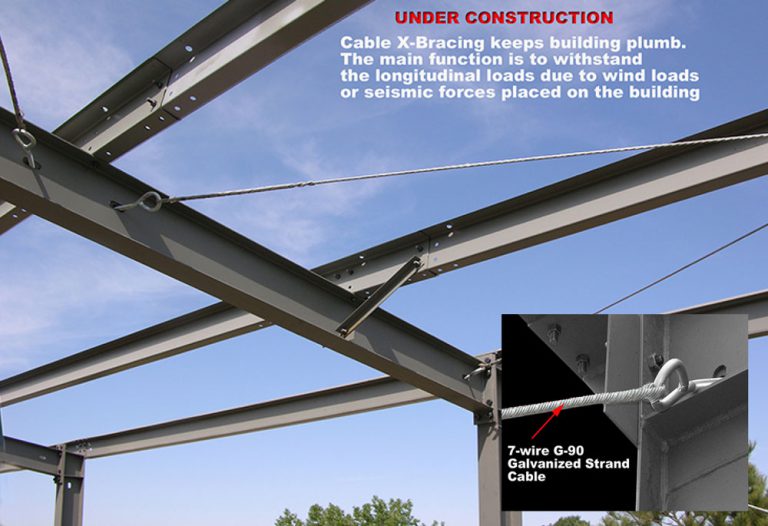

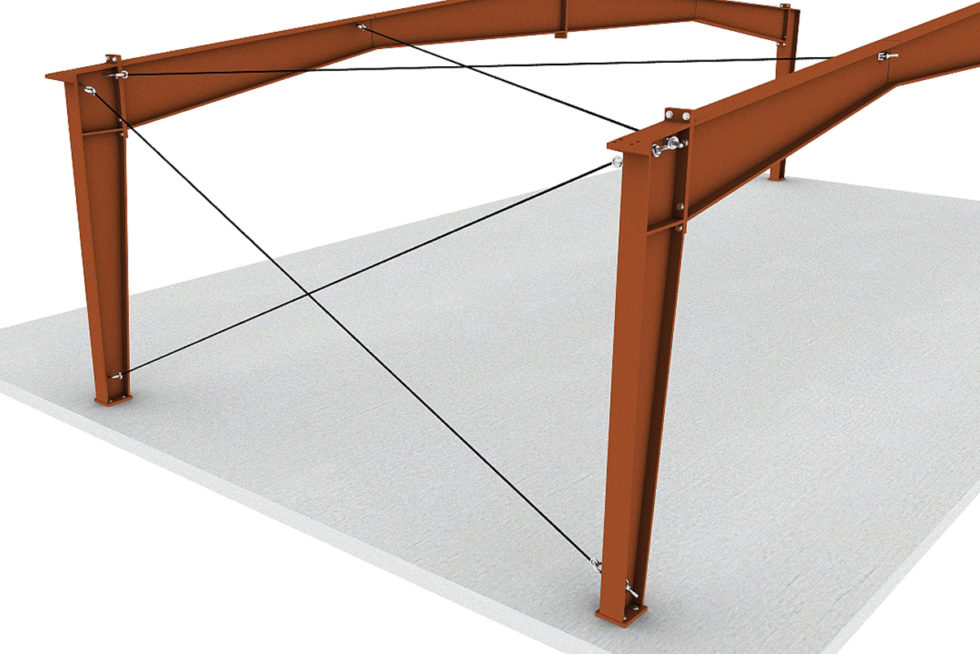

Cable Bracing For Metal Building - Longer buildings can have sufficient shear capacity if properly designed. This is often because the capacity of the light gauge steel panels in shear is insufficient to transfer wind and seismic loads to the foundation. Bracing ends are designed for use with standard guy strands 9/16. The standard product consists of. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. Most metal buildings require cable braces (x braces), or steel rod bracing, or some kind of x bracing. Stainless steel cables are versatile and widely used, but choosing the right wire size is essential for both safety and aesthetic appeal when installing cable deck railings. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Every part can be customized to your needs. Dmi offers many cable bracing solutions to our valued metal building manufacturer customers. Tengco has the cable bracing your company needs for its next steel building construction project. Longer buildings can have sufficient shear capacity if properly designed. Stainless steel cables are versatile and widely used, but choosing the right wire size is essential for both safety and aesthetic appeal when installing cable deck railings. Dmi offers many cable bracing solutions to our valued metal building manufacturer customers. Every part can be customized to your needs. This is often because the capacity of the light gauge steel panels in shear is insufficient to transfer wind and seismic loads to the foundation. A portal frame is comprised of. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. Most metal buildings require cable braces (x braces), or steel rod bracing, or some kind of x bracing. Longitudinal bracing is a required part of the building system, resisting forces due to wind, earthquakes, cranes, and other stability considerations. Longitudinal bracing is a required part of the building system, resisting forces due to wind, earthquakes, cranes, and other stability considerations. This is often because the capacity of the light gauge steel panels in shear is insufficient to transfer wind and seismic loads to the foundation. Longer buildings can have sufficient shear capacity if properly designed. Cable bracing in the. Longitudinal bracing is a required part of the building system, resisting forces due to wind, earthquakes, cranes, and other stability considerations. Most metal buildings require cable braces (x braces), or steel rod bracing, or some kind of x bracing. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or. Stainless steel cables are versatile and widely used, but choosing the right wire size is essential for both safety and aesthetic appeal when installing cable deck railings. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Most metal buildings require cable braces (x braces), or steel. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Longitudinal bracing is a required part of the building system, resisting forces due to wind, earthquakes, cranes, and other stability. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. Tengco has the cable bracing your company needs for its next steel building construction project. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Most metal buildings require cable. Dmi offers many cable bracing solutions to our valued metal building manufacturer customers. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. This is often because the capacity of the light gauge steel panels in shear is insufficient to transfer wind and seismic loads to the. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. A portal frame is comprised of. Most metal buildings require cable braces (x braces), or steel rod bracing, or some kind of x bracing. This is often because the capacity of the light gauge steel panels in shear is insufficient to transfer wind. Every part can be customized to your needs. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Longer buildings can have sufficient shear capacity if properly designed. Longitudinal bracing. Most metal buildings require cable braces (x braces), or steel rod bracing, or some kind of x bracing. Bracing ends are designed for use with standard guy strands 9/16. Stainless steel cables are versatile and widely used, but choosing the right wire size is essential for both safety and aesthetic appeal when installing cable deck railings. These offerings include but. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Longitudinal bracing is a required part of the building system, resisting forces due to wind, earthquakes, cranes, and other stability considerations. Tengco has the cable bracing your company needs for its next steel building construction project. A. Longer buildings can have sufficient shear capacity if properly designed. Bracing ends are designed to provide fast and efficient guy strands termination used in metal building construction. Longitudinal bracing is a required part of the building system, resisting forces due to wind, earthquakes, cranes, and other stability considerations. Dmi offers many cable bracing solutions to our valued metal building manufacturer customers. Stainless steel cables are versatile and widely used, but choosing the right wire size is essential for both safety and aesthetic appeal when installing cable deck railings. This is often because the capacity of the light gauge steel panels in shear is insufficient to transfer wind and seismic loads to the foundation. The standard product consists of. Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Bracing ends are designed for use with standard guy strands 9/16. Every part can be customized to your needs. These offerings include but are not limited to cable bracing kits with eyebolts, nut, hillside.Cable Bracing For Steel Buildings

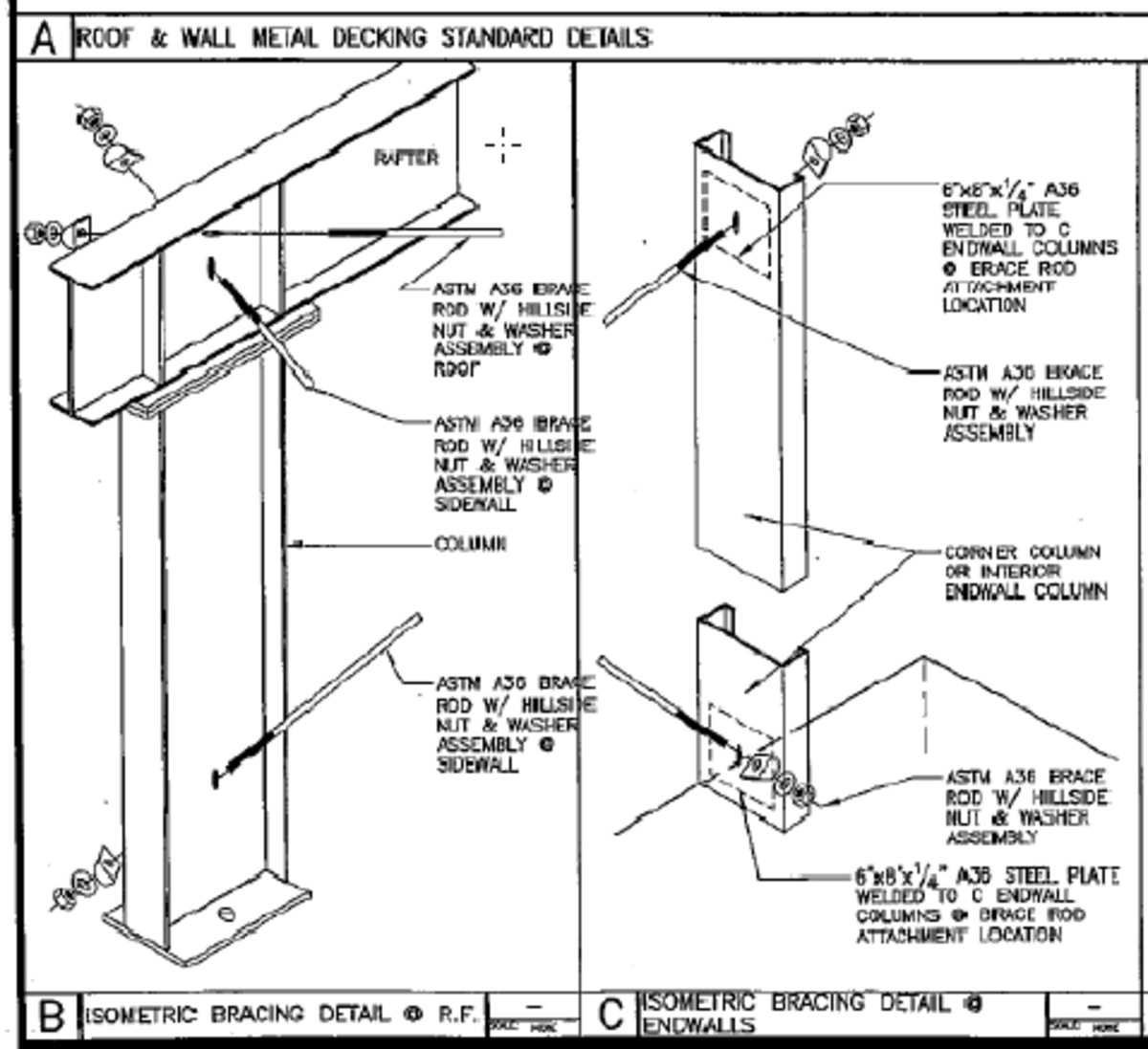

Metal Building Wind Bracing Steel Building Seismic Bracing Ceco

steel cable bracing Google Search

Metal Building Bracing Conditions Steel Building Windframing

Sunward Steel Buildings Quality Features and Accessories

Metal Building Bracing Conditions Steel Building Windframing

Installing Metal Buildings 101

Metal Building Bracing Conditions Steel Building Windframing

Framing Systems Vulcan Steel Structures

Cable Bracing for Steel Buildings Owlcation

Most Metal Buildings Require Cable Braces (X Braces), Or Steel Rod Bracing, Or Some Kind Of X Bracing.

Tengco Has The Cable Bracing Your Company Needs For Its Next Steel Building Construction Project.

A Portal Frame Is Comprised Of.

Related Post: