How Many Hours A Compressor Run In A Office Building

How Many Hours A Compressor Run In A Office Building - Smaller air compressors may run continuously for 30 minutes to 1 hour before needing a. With the system at normal system pressure, the air source (compressor or shop air) shall be shut off for 4 hours. Yes, an air compressor can run 24 hours if it is designed for continuous duty. Every compressor is built for a certain duty cycle—the percentage of time it can run before it needs a break. Depending on the size and type of compressor, air compressors can be left running anywhere from a few hours to 24 hours a day, seven days a week. For example, if a compressor has a duty cycle of 60%,. Knowing your compressor and its. In this article, we’ll break down the key factors that determine the compressor’s. Centrifugal compressors are typically designed to run. If the low air pressure alarm goes off within this period, the air. If the low air pressure alarm goes off within this period, the air. Regular maintenance is crucial for safe operation. But how much time does the ac compressor actually run during an average cycle? At its core, the duty cycle of an air compressor refers to how long the compressor runs compared to how long it rests during a total cycle. Reciprocal compressors are generally not rated to be run continuously, nor are the motors they put on them. Generally, small compressors with tanks smaller than six gallons should cycle every few minutes, while larger ones with tanks over 20 gallons can operate for longer periods of time before cycling. We also recommend assessing your facility’s electrical system. With the system at normal system pressure, the air source (compressor or shop air) shall be shut off for 4 hours. The length of time you should run an air compressor before using it can vary depending on the manufacturer’s recommendations. In this article, we’ll break down the key factors that determine the compressor’s. The run time for an air compressor can vary based on its size and capacity. When selecting an air compressor for continuous operation, it is crucial to consider the duty cycle, which indicates the amount of time the compressor can run within a specified. Every compressor is built for a certain duty cycle—the percentage of time it can run before. Exceeding this puts excessive wear on the motor and pump. At its core, the duty cycle of an air compressor refers to how long the compressor runs compared to how long it rests during a total cycle. With the system at normal system pressure, the air source (compressor or shop air) shall be shut off for 4 hours. Air compressors. The length of time an air compressor should run depends on the specific tasks and the capacity of the compressor. If the low air pressure alarm goes off within this period, the air. The cost of electricity (per kwh) or fuel (per gallon or liter). Centrifugal compressors are typically designed to run. A rotary screw air compressor should last between. Reciprocal compressors are generally not rated to be run continuously, nor are the motors they put on them. Generally, small compressors with tanks smaller than six gallons should cycle every few minutes, while larger ones with tanks over 20 gallons can operate for longer periods of time before cycling. But how much time does the ac compressor actually run during. But how much time does the ac compressor actually run during an average cycle? Smaller air compressors may run continuously for 30 minutes to 1 hour before needing a. Generally, small compressors with tanks smaller than six gallons should cycle every few minutes, while larger ones with tanks over 20 gallons can operate for longer periods of time before cycling.. Exceeding the duty cycle can. That's running for a culmitive of 32 minutes a day across 8 separate. Yes, an air compressor can run 24 hours if it is designed for continuous duty. If the low air pressure alarm goes off within this period, the air. Typically, it is recommended to let the. Reciprocal compressors are generally not rated to be run continuously, nor are the motors they put on them. Regular maintenance is crucial for safe operation. The run time for an air compressor can vary based on its size and capacity. Exceeding this puts excessive wear on the motor and pump. Air compressors are versatile tools found in. Depending on the size and type of compressor, air compressors can be left running anywhere from a few hours to 24 hours a day, seven days a week. With the system at normal system pressure, the air source (compressor or shop air) shall be shut off for 4 hours. Reciprocal compressors are generally not rated to be run continuously, nor. Air compressors are versatile tools found in. That's running for a culmitive of 32 minutes a day across 8 separate. Every compressor is built for a certain duty cycle—the percentage of time it can run before it needs a break. Typically, it is recommended to let the. The good news is that these. The length of time an air compressor should run depends on the specific tasks and the capacity of the compressor. Knowing your compressor and its. We also recommend assessing your facility’s electrical system. At its core, the duty cycle of an air compressor refers to how long the compressor runs compared to how long it rests during a total cycle.. Regular maintenance is crucial for safe operation. Reciprocal compressors are generally not rated to be run continuously, nor are the motors they put on them. This estimate can vary based on the type of. Smaller air compressors may run continuously for 30 minutes to 1 hour before needing a. With the system at normal system pressure, the air source (compressor or shop air) shall be shut off for 4 hours. Exceeding this puts excessive wear on the motor and pump. But how much time does the ac compressor actually run during an average cycle? Depending on the size and type of compressor, air compressors can be left running anywhere from a few hours to 24 hours a day, seven days a week. When selecting an air compressor for continuous operation, it is crucial to consider the duty cycle, which indicates the amount of time the compressor can run within a specified. For example, if a compressor has a duty cycle of 60%,. Yes, an air compressor can run 24 hours if it is designed for continuous duty. A rotary screw air compressor should last between 60,000 and 80,000 hours, which translates to anywhere between 20 and 30 years. The run time for an air compressor can vary based on its size and capacity. Air compressors are versatile tools found in. In this article, we’ll break down the key factors that determine the compressor’s. The good news is that these.Many condensing units of air conditioners are installed on concrete

Air Conditioner Compressor Installed on Roof Building. Industrial Air

Pineland Compressor & Auxiliary Buildings

Complex compressor unit behind the office building Stock Photo Alamy

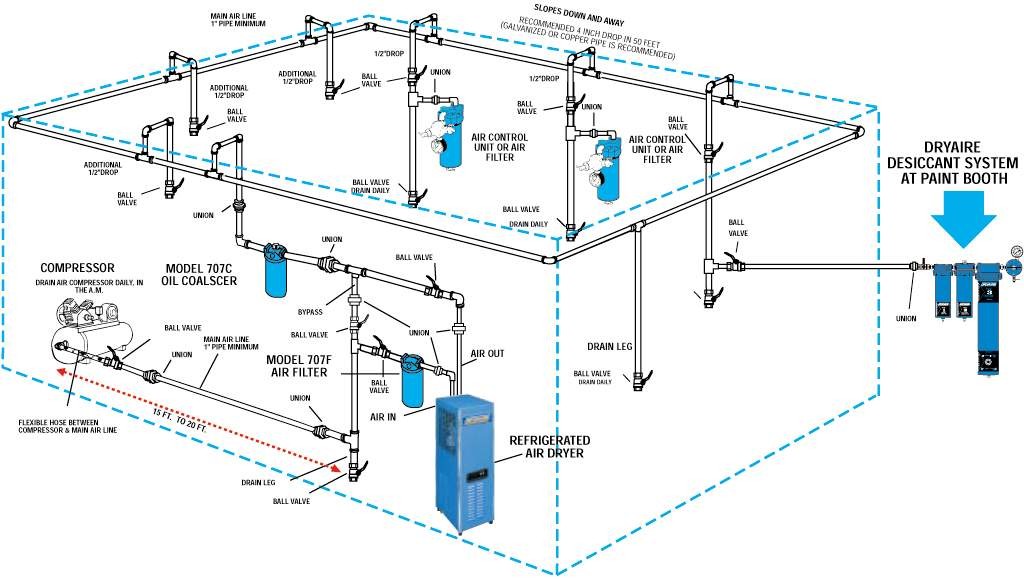

Complete Compressed Air Installations

Compressors, air conditioners on the roof of the office building

Many condensing units of air conditioners are installed on concrete

Troubleshooting An Air Compressor Fox Family HVAC

Compressor running time Download Scientific Diagram

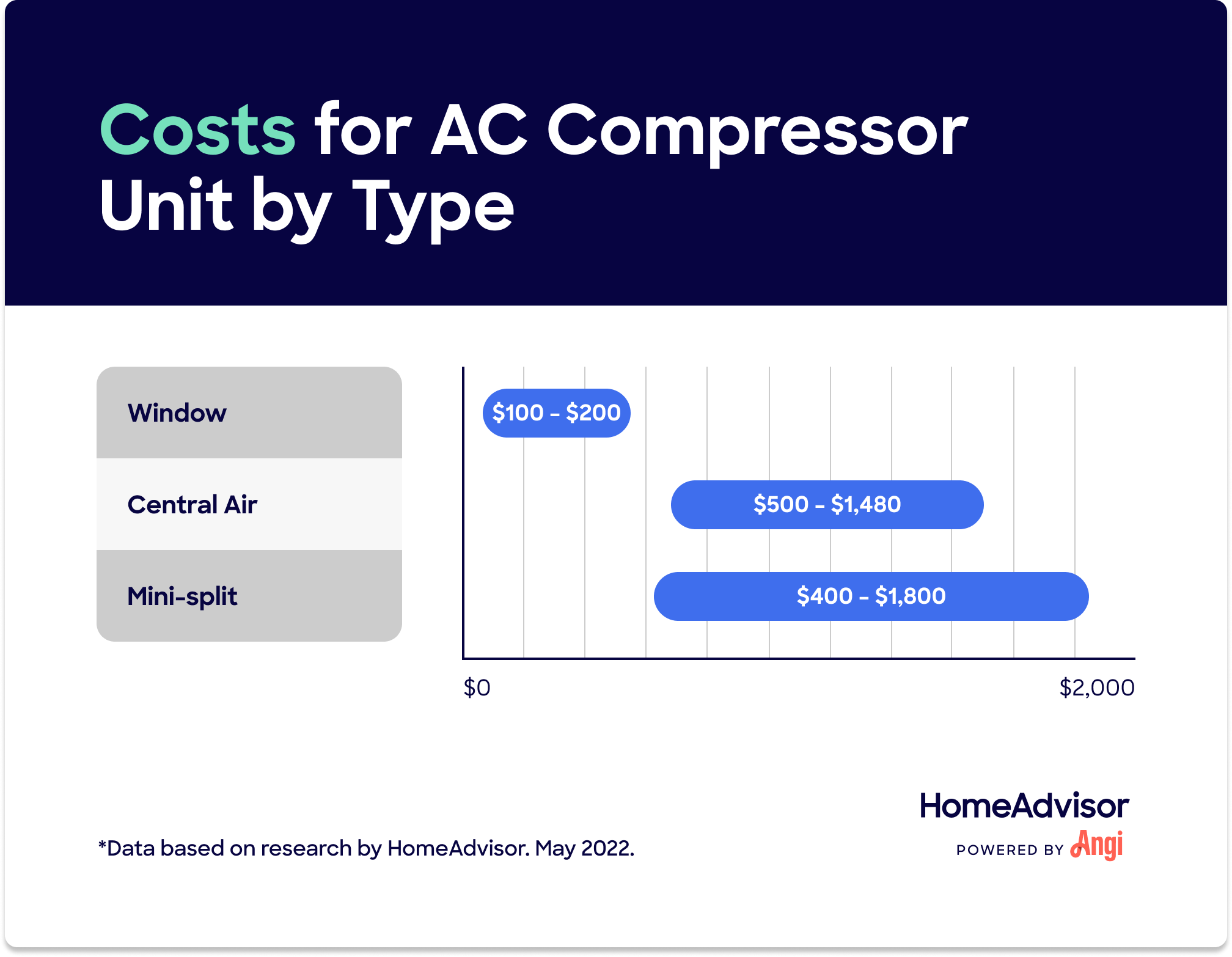

How Much Does an AC Compressor Cost?

The Length Of Time An Air Compressor Should Run Depends On The Specific Tasks And The Capacity Of The Compressor.

Every Compressor Is Built For A Certain Duty Cycle—The Percentage Of Time It Can Run Before It Needs A Break.

Generally, Small Compressors With Tanks Smaller Than Six Gallons Should Cycle Every Few Minutes, While Larger Ones With Tanks Over 20 Gallons Can Operate For Longer Periods Of Time Before Cycling.

Typically, It Is Recommended To Let The.

Related Post: