How Much Does It Take To Build An Oil Terminal

How Much Does It Take To Build An Oil Terminal - Eurotankworks carries out engineering design of oil terminals of all categories, groups and types. How do oil depots and terminal storage facilities balance safety and operational efficiency? Explore advanced designs for spill prevention and containment. Lamberson, international construction consulting, llc. What should be the pipeline’s destination? These facilities temporarily store crude oil products as. Which production areas need new takeaway capacity? There are four categories of pipeline construction costs; Note that crude oils can be classified as heavy or light, and sweet or sour, depending on the density,. How we construct a crude oil tank terminal crude oil tank terminals are a critical component of the enbridge energy transportation system. How long will it take until global tank storage. Lamberson, international construction consulting, llc. For oil markets it is of vital importance to have spare tank capacity to absorb imbalances. We elaborate project documentation and construction design. More than half of our average annual amount of work includes constructing oil tank farms and liquid bulk terminals: How much capacity should the pipeline have? Explore advanced designs for spill prevention and containment. The cost of crude oil processed by a refinery depends on market prices for crude oil. When is the ideal time to. These facilities temporarily store crude oil products as. The cost of crude oil processed by a refinery depends on market prices for crude oil. How we construct a crude oil tank terminal crude oil tank terminals are a critical component of the enbridge energy transportation system. Lamberson, international construction consulting, llc. Note that crude oils can be classified as heavy or light, and sweet or sour, depending on. Fuel and lubricants, oil residue, bitumen, etc. Lamberson, international construction consulting, llc. We elaborate project documentation and construction design. There are four categories of pipeline construction costs; Explore advanced designs for spill prevention and containment. There are four categories of pipeline construction costs; For oil markets it is of vital importance to have spare tank capacity to absorb imbalances. How much capacity should the pipeline have? How do oil depots and terminal storage facilities balance safety and operational efficiency? Harder mechanical contractors provides tailored solutions for complex construction and installation for oil terminal operators. Lamberson, international construction consulting, llc. What should be the pipeline’s destination? Which production areas need new takeaway capacity? For oil markets it is of vital importance to have spare tank capacity to absorb imbalances. Fuel and lubricants, oil residue, bitumen, etc. When is the ideal time to. How do oil depots and terminal storage facilities balance safety and operational efficiency? Harder mechanical contractors provides tailored solutions for complex construction and installation for oil terminal operators. There are four categories of pipeline construction costs; More than half of our average annual amount of work includes constructing oil tank farms and liquid bulk. Which production areas need new takeaway capacity? These facilities temporarily store crude oil products as. What should be the pipeline’s destination? How much capacity should the pipeline have? Harder mechanical contractors provides tailored solutions for complex construction and installation for oil terminal operators. Harder mechanical contractors provides tailored solutions for complex construction and installation for oil terminal operators. These facilities temporarily store crude oil products as. Fuel and lubricants, oil residue, bitumen, etc. More than half of our average annual amount of work includes constructing oil tank farms and liquid bulk terminals: For oil markets it is of vital importance to have spare. However, the current oversupply is immense. How much capacity should the pipeline have? When is the ideal time to. Lamberson, international construction consulting, llc. There are four categories of pipeline construction costs; What should be the pipeline’s destination? Fuel and lubricants, oil residue, bitumen, etc. However, the current oversupply is immense. How we construct a crude oil tank terminal crude oil tank terminals are a critical component of the enbridge energy transportation system. There are four categories of pipeline construction costs; Fuel and lubricants, oil residue, bitumen, etc. The cost of crude oil processed by a refinery depends on market prices for crude oil. Lamberson, international construction consulting, llc. What should be the pipeline’s destination? Note that crude oils can be classified as heavy or light, and sweet or sour, depending on the density,. These facilities temporarily store crude oil products as. How we construct a crude oil tank terminal crude oil tank terminals are a critical component of the enbridge energy transportation system. Which production areas need new takeaway capacity? How long will it take until global tank storage. More than half of our average annual amount of work includes constructing oil tank farms and liquid bulk terminals: When is the ideal time to. Lamberson, international construction consulting, llc. We elaborate project documentation and construction design. There are four categories of pipeline construction costs; For oil markets it is of vital importance to have spare tank capacity to absorb imbalances. The cost of crude oil processed by a refinery depends on market prices for crude oil. Explore advanced designs for spill prevention and containment. What should be the pipeline’s destination? How much capacity should the pipeline have? However, the current oversupply is immense. How do oil depots and terminal storage facilities balance safety and operational efficiency?Enterprise Products wins U.S. approval to build Texas oil terminal

Chelsea River Bulk Petroleum Storage Facilities NPDES Permits US EPA

Petroleum Terminals « Norwest Engineering

Guide To Oil Terminals Everything You Wanted To Know

Aramco and TotalEnergies to Build 11 Billion Saudi Petrochemicals

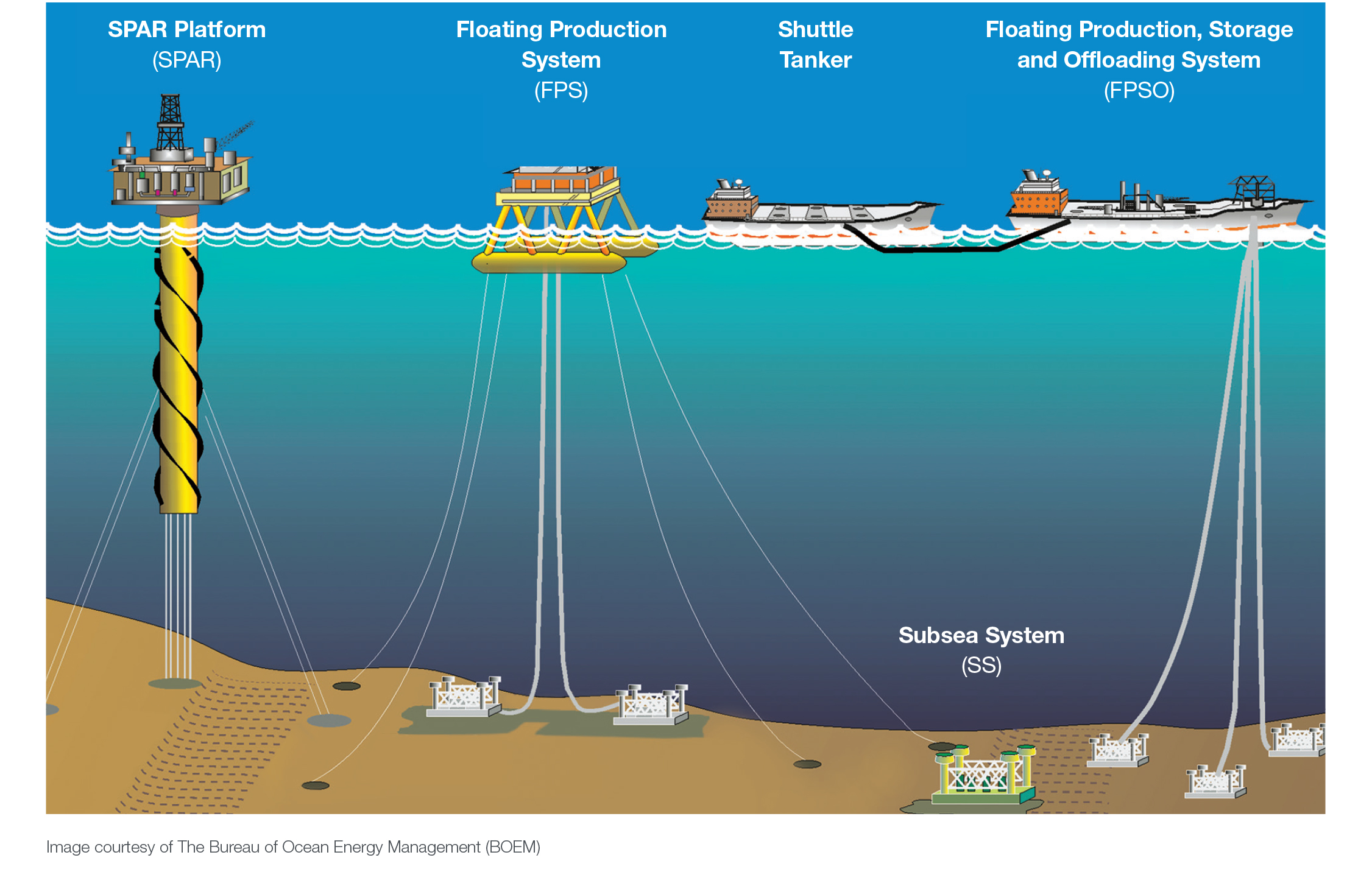

Offshore Oil and Gas American Geosciences Institute

Enterprise plans crude export terminal offshore of Texas

Oil Well Drilling Explained HubPages

How Much Does a Well Cost? (2024 Well Drilling Cost Guide)

Aerial View of Liquid Bulk Petroleum and Gasoline Terminals, Pipeline

Fuel And Lubricants, Oil Residue, Bitumen, Etc.

Oil Product Tankers Usually Contract From Short Term To Up To 5 Years (The Futures Curve Is Illiquid Beyond A 5 Year Window).

Harder Mechanical Contractors Provides Tailored Solutions For Complex Construction And Installation For Oil Terminal Operators.

The Cost Per Category, Expressed As A Percentage Of Total Construction Costs, Tends To Vary By Both Location And Year.

Related Post: