How To Build A Laser

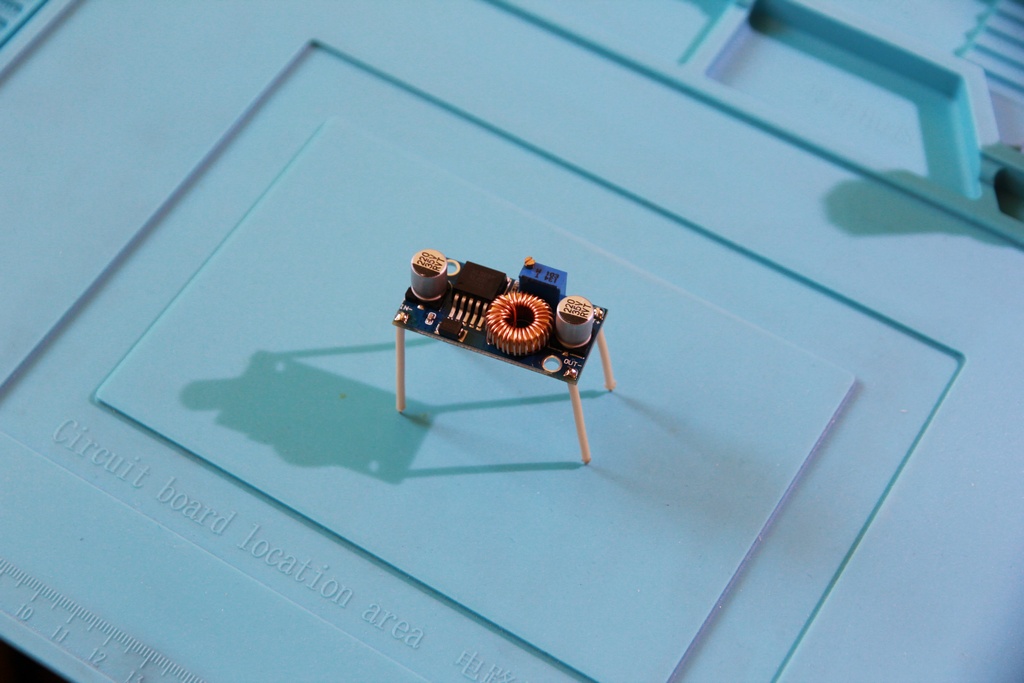

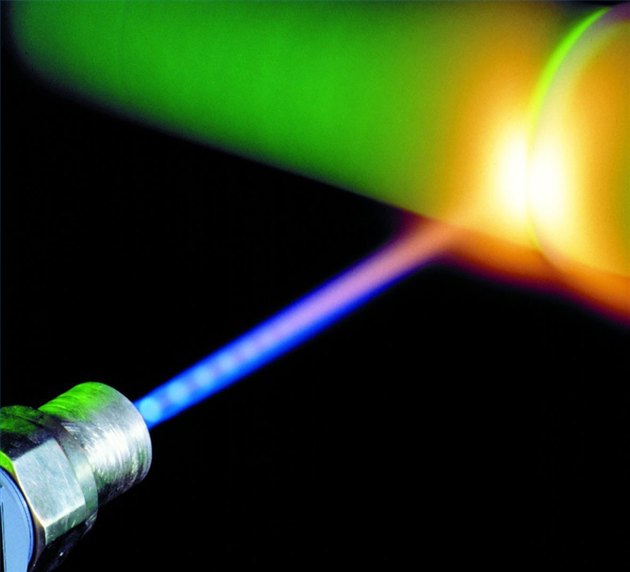

How To Build A Laser - Three years ago i bought my first co2 laser, a k40. There are 4 main elements that are required to start the generation of light and make your own laser; Do you want to build your first diy laser cutter? These projects range from easy and affordable to more advanced and costly so it becomes easy for you to choose the one that fits your skill. Or buy just the laser assembly from the internet. Do you want to build you own laser module? Lasers work, or “lase,” by stimulating electrons to emit light of a particular wavelength. Endurance provides customers with an ultimate tech support, full guidance and tutorials telling how to make and tune your own laser. Today, lasers are used for purposes ranging from measurement to reading encoded data, and there are several ways to make a laser, depending on your budget and skills. His first build involves gluing a small square. This beam is concentrated onto a very small area, creating an intense heat zone that melts the material surfaces at the joint, and. Do you want to build you own laser module? But first the story about this project. Either to get a dvd drive for pc and extract only the diode assembly (aka sled). I wanted a larger cutting area than my. Three years ago i bought my first co2 laser, a k40. In this instructable i want to show you, how you can build your own diy co2 laser for less then 1000€. If you've ever wanted to make your own laser pointer, or do some cool things with lasers, check out these posts! Laser cutters are part of a cutting technology that uses laser beams to vaporize materials, resulting in a cutting edge. The black one is responsible for leaving a deep etching on the brass, while the red layer. Then make sure the laser etching parameters are set correctly. Either to get a dvd drive for pc and extract only the diode assembly (aka sled). How to build a laser: I wanted a larger cutting area than my. Whether you’re preserving a cherished family recipe or creating a special gift, engraving a handwritten recipe on a cutting board transforms. The gain medium, the pumping energy, cavity reflections and the output coupler: These projects range from easy and affordable to more advanced and costly so it becomes easy for you to choose the one that fits your skill. If you've ever wanted to make your own laser pointer, or do some cool things with lasers, check out these posts! Or. In this instructable i want to show you, how you can build your own diy co2 laser for less then 1000€. This beam is concentrated onto a very small area, creating an intense heat zone that melts the material surfaces at the joint, and. It worked okay, but this machine didn't live up to my expectations. Today, lasers are used. In this article, we will provide you with a roundup of 13 different diy laser cutter and engraver projects that you can build at home. Prior to recent times, they were used mostly by industrial manufacturing establishments, but are now used by. But first the story about this project. There are four key elements on ‘how to make a laser’. I've included every file you need for building it in this instructable. But first the story about this project. In this video i share my process of designing and building a co2 laser cutter using a combination of 'v' & 't' slotted aluminium profile 3d printed parts. Lasers work, or “lase,” by stimulating electrons to emit light of a particular. Do you want to build your first diy laser cutter? In this article, we will walk you through the process of creating your very own laser. I've included every file you need for building it in this instructable. You can get old dvd rw drives on ebay for >15usd, or just look around and. What do i need to build. This beam is concentrated onto a very small area, creating an intense heat zone that melts the material surfaces at the joint, and. Endurance provides customers with an ultimate tech support, full guidance and tutorials telling how to make and tune your own laser. Lasers work, or “lase,” by stimulating electrons to emit light of a particular wavelength. Do you. Do you want to build you own laser module? In this video i share my process of designing and building a co2 laser cutter using a combination of 'v' & 't' slotted aluminium profile 3d printed parts. Do you want to build your first diy laser cutter? His first build involves gluing a small square. If you've ever wanted to. It worked okay, but this machine didn't live up to my expectations. This is a full step by step instruction on how to build your own lasercutter! In this video i share my process of designing and building a co2 laser cutter using a combination of 'v' & 't' slotted aluminium profile 3d printed parts. Laser cutters are part of. Do you want to build you own laser module? This beam is concentrated onto a very small area, creating an intense heat zone that melts the material surfaces at the joint, and. Or buy just the laser assembly from the internet. In this video i share my process of designing and building a co2 laser cutter using a combination of. I've included every file you need for building it in this instructable. In this video i share my process of designing and building a co2 laser cutter using a combination of 'v' & 't' slotted aluminium profile 3d printed parts. There are 4 main elements that are required to start the generation of light and make your own laser; Today, lasers are used for purposes ranging from measurement to reading encoded data, and there are several ways to make a laser, depending on your budget and skills. If you've ever wanted to make your own laser pointer, or do some cool things with lasers, check out these posts! It worked okay, but this machine didn't live up to my expectations. Prior to recent times, they were used mostly by industrial manufacturing establishments, but are now used by. The gain medium, the pumping energy, cavity reflections and the output coupler: Load your design into lightburn software, adjusting its size and position to fit you brass wax seals. One of the most exciting applications of this technology is in the creation of stencils. What do i need to build a laser? Provide a source of energy. Whether you’re preserving a cherished family recipe or creating a special gift, engraving a handwritten recipe on a cutting board transforms an everyday kitchen item into a treasured keepsake.the xtool p2 laser engraver makes this project doable for a beginner or a. You can get old dvd rw drives on ebay for >15usd, or just look around and. But first the story about this project. Then make sure the laser etching parameters are set correctly.The Endurance laser kit pack build your own laser module, FREE GUIDE!

How to Build a Laser Pointer 8 Steps (with Pictures) wikiHow

How to build a laser ThingsGeek

How to Build a Laser Hunker

Powerful Burning Laser 5 Steps (with Pictures) Instructables

How to Build a High Powered Laser 12 Steps (with Pictures)

How to Make a Laser Pointer YouTube

How to Make a Laser (with Pictures) wikiHow

Diy 6000mWatts Laser Gun with OPT Lasers module MakeMan YouTube

How to Make a Laser (with Pictures) wikiHow

Or Buy Just The Laser Assembly From The Internet.

There Are Four Key Elements On ‘How To Make A Laser’ To Get Right When You Make Your Own Laser.

Three Years Ago I Bought My First Co2 Laser, A K40.

These Projects Range From Easy And Affordable To More Advanced And Costly So It Becomes Easy For You To Choose The One That Fits Your Skill.

Related Post: