Injection Mold Building

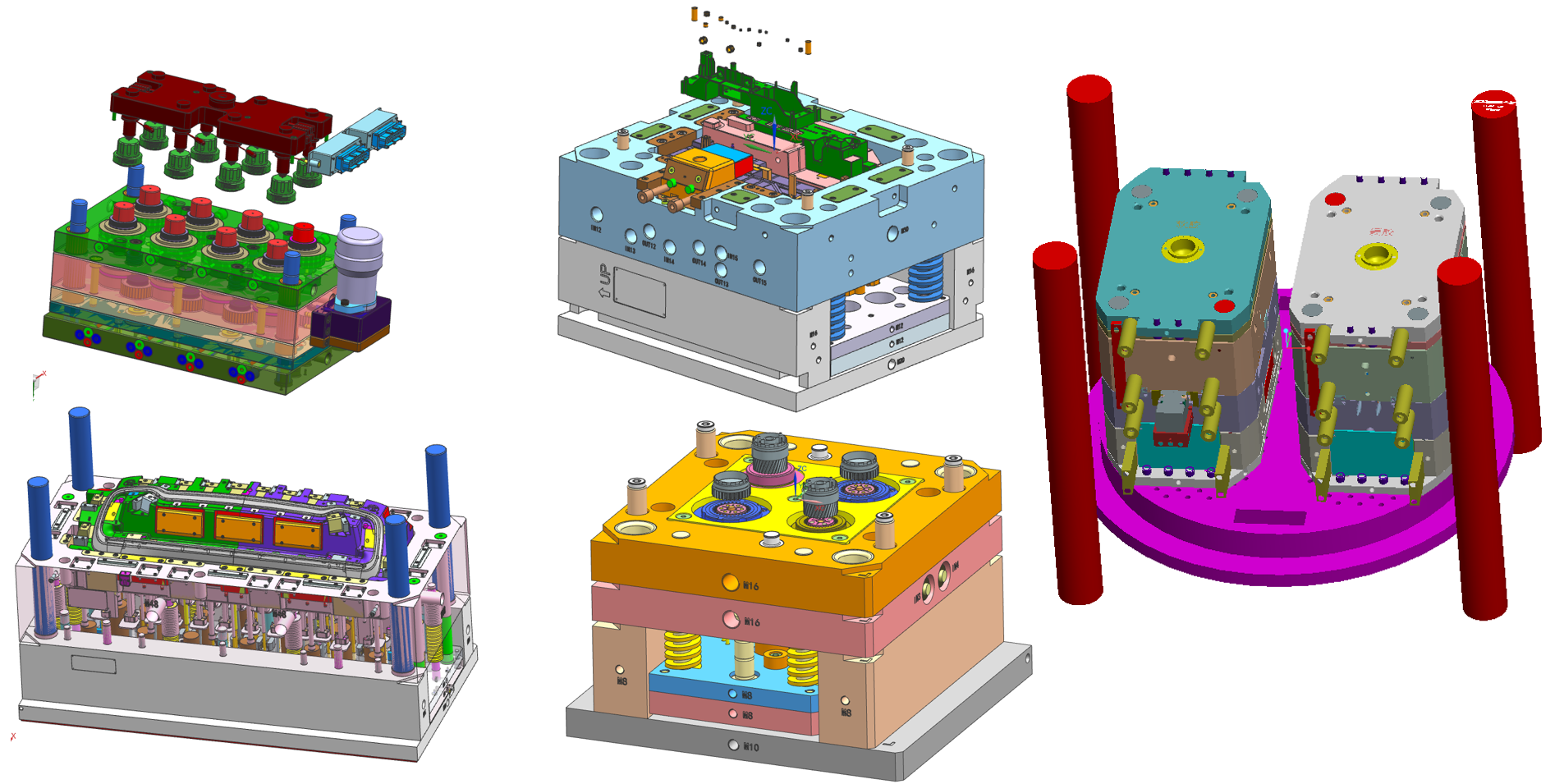

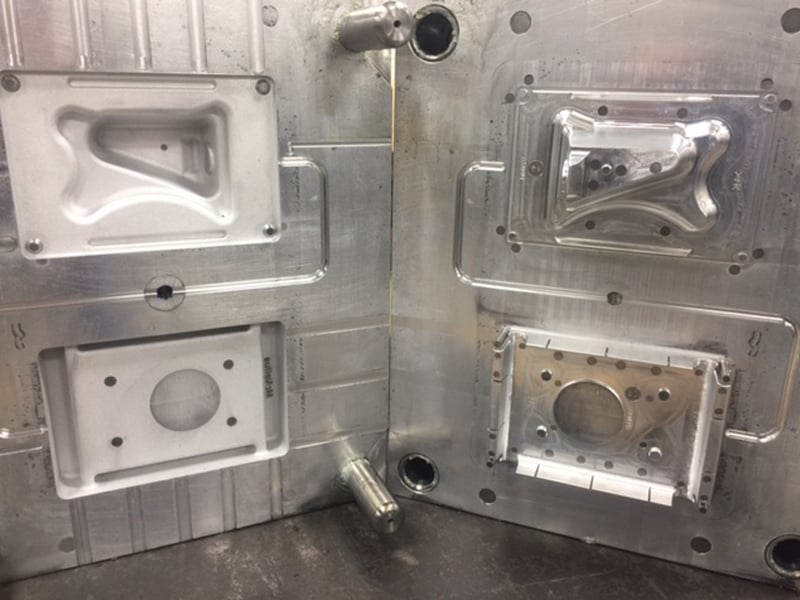

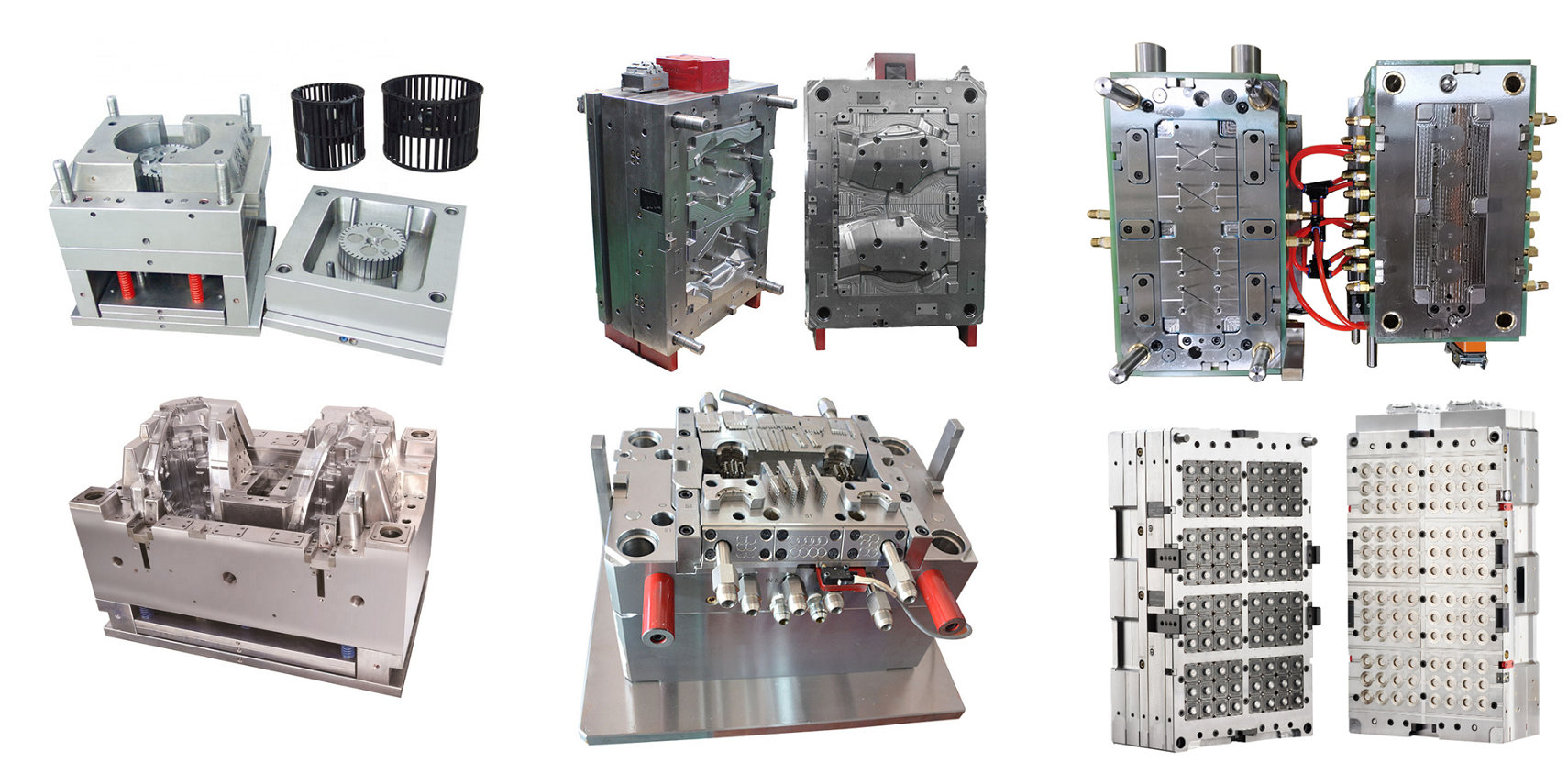

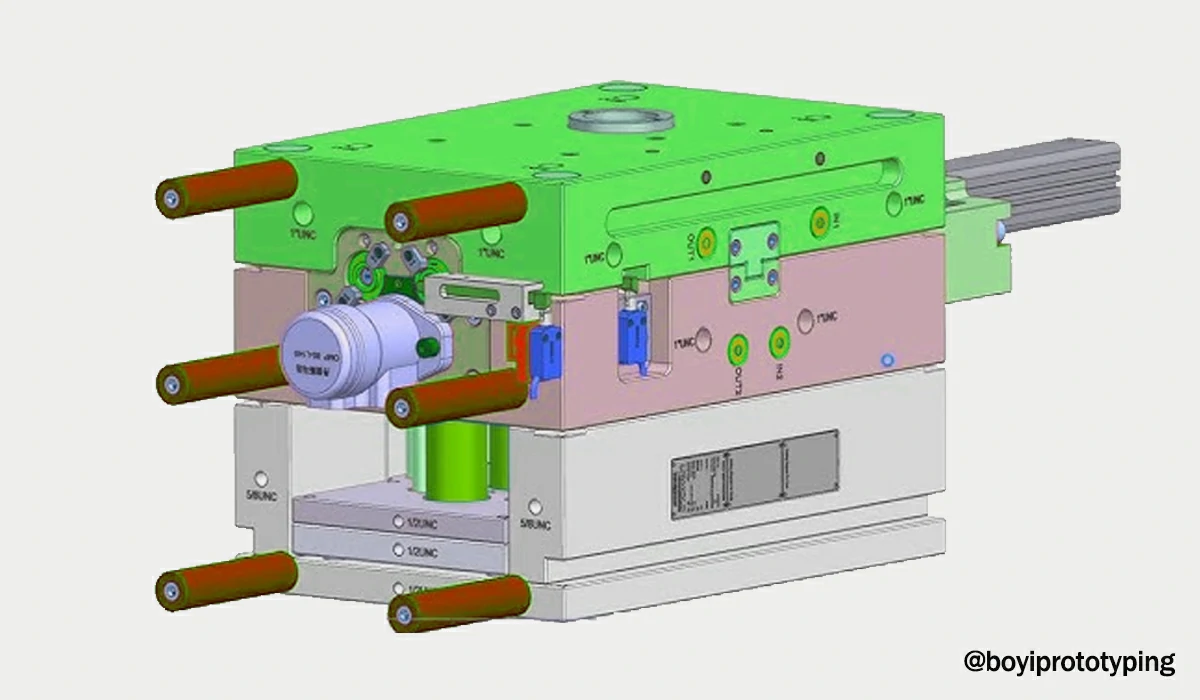

Injection Mold Building - There are a handful of different materials used for building injection molds. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Plastic injection molding is a manufacturing process that transforms thermoplastic materials into intricate components with exceptional accuracy and consistency. Whether you're building an injection molding plant or installing a new cell, follow these steps to ensure a successful outcome. Making plastic molds requires designing the mold, selecting the appropriate material, building the mold, injecting the material into the mold cavity using an injection molding machine, cooling. Discover the key trends shaping the future of injection molding in 2025 and beyond. In this video, you’ll learn the fundamentals of mold design. Plastech corporation offers a comprehensive range of mold building services, including product design optimization, mold design, tool construction, mold flow analysis, mold. Before manufacturing your plastic part, the first step is to produce a mold, which can be a difficult task given the many nuanced design, material, and process requirements involved in tooling. In this method, molten plastic is injected into a mold cavity under high pressure. Injection molding is one of the most widely used processes for producing plastic parts. There are a handful of different materials used for building injection molds. In this video, you’ll learn the fundamentals of mold design. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Plastic injection molding is a manufacturing process that transforms thermoplastic materials into intricate components with exceptional accuracy and consistency. Explore advancements in technology, mold transferability, nearshoring, sustainability,. Making plastic molds requires designing the mold, selecting the appropriate material, building the mold, injecting the material into the mold cavity using an injection molding machine, cooling. Most steel molds can produce over a million parts before. Before manufacturing your plastic part, the first step is to produce a mold, which can be a difficult task given the many nuanced design, material, and process requirements involved in tooling. In this method, molten plastic is injected into a mold cavity under high pressure. Before manufacturing your plastic part, the first step is to produce a mold, which can be a difficult task given the many nuanced design, material, and process requirements involved in tooling. In this method, molten plastic is injected into a mold cavity under high pressure. Plastech corporation offers a comprehensive range of mold building services, including product design optimization, mold. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Plastic injection molding is a manufacturing process that transforms thermoplastic materials into intricate components with exceptional accuracy and consistency. In this method, molten plastic is injected into a mold cavity under high pressure. Injection molding is one of the. Most steel molds can produce over a million parts before. There are a handful of different materials used for building injection molds. Plastech corporation offers a comprehensive range of mold building services, including product design optimization, mold design, tool construction, mold flow analysis, mold. Whether you're building an injection molding plant or installing a new cell, follow these steps to. In this method, molten plastic is injected into a mold cavity under high pressure. Plastic injection molding is a manufacturing process that transforms thermoplastic materials into intricate components with exceptional accuracy and consistency. It’s important to understand the application of each and the associated pros and cons. Whether you're building an injection molding plant or installing a new cell, follow. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Injection molding is one of the most widely used processes for producing plastic parts. Discover the key trends shaping the future of injection molding in 2025 and beyond. There are a handful of different materials used for building injection. Most steel molds can produce over a million parts before. Before manufacturing your plastic part, the first step is to produce a mold, which can be a difficult task given the many nuanced design, material, and process requirements involved in tooling. Injection molding is one of the most widely used processes for producing plastic parts. It’s important to understand the. Explore advancements in technology, mold transferability, nearshoring, sustainability,. In this method, molten plastic is injected into a mold cavity under high pressure. Whether you're building an injection molding plant or installing a new cell, follow these steps to ensure a successful outcome. Discover the key trends shaping the future of injection molding in 2025 and beyond. Plastech corporation offers a. In this video, you’ll learn the fundamentals of mold design. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. It’s important to understand the application of each and the associated pros and cons. Explore advancements in technology, mold transferability, nearshoring, sustainability,. Making plastic molds requires designing the mold,. Before manufacturing your plastic part, the first step is to produce a mold, which can be a difficult task given the many nuanced design, material, and process requirements involved in tooling. Making plastic molds requires designing the mold, selecting the appropriate material, building the mold, injecting the material into the mold cavity using an injection molding machine, cooling. In this. Most steel molds can produce over a million parts before. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Explore advancements in technology, mold transferability, nearshoring, sustainability,. There are a handful of different materials used for building injection molds. Discover the key trends shaping the future of injection. Plastic injection molding is a manufacturing process that transforms thermoplastic materials into intricate components with exceptional accuracy and consistency. Whether you're building an injection molding plant or installing a new cell, follow these steps to ensure a successful outcome. In this method, molten plastic is injected into a mold cavity under high pressure. In this video, you’ll learn the fundamentals of mold design. Explore advancements in technology, mold transferability, nearshoring, sustainability,. Plastech corporation offers a comprehensive range of mold building services, including product design optimization, mold design, tool construction, mold flow analysis, mold. There are a handful of different materials used for building injection molds. Discover the key trends shaping the future of injection molding in 2025 and beyond. Injection molding is one of the most widely used processes for producing plastic parts. Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Before manufacturing your plastic part, the first step is to produce a mold, which can be a difficult task given the many nuanced design, material, and process requirements involved in tooling.Mold Building Deluxe Plastics Wisconsin Custom Injection Molding

Injection Mold Building Liberty Plastics Molding

Injection Mold Building OKAYMOLD

EDM for Injection Mold Building Basilius Inc.

PlasTech Custom Injection Mold Building Plastech Tooling

How to make Injection Molding design in Solidworks 3/5 YouTube

PlasTech Custom Injection Mold Building

Injection Mold Building OKAYMOLD

Injection Mold Building Key Components and Structure Overview BOYI

What is Injection Molding and How Does it Work Definition & Working

It’s Important To Understand The Application Of Each And The Associated Pros And Cons.

Making Plastic Molds Requires Designing The Mold, Selecting The Appropriate Material, Building The Mold, Injecting The Material Into The Mold Cavity Using An Injection Molding Machine, Cooling.

Most Steel Molds Can Produce Over A Million Parts Before.

Related Post: