Manufacturing Costs For Building A Project

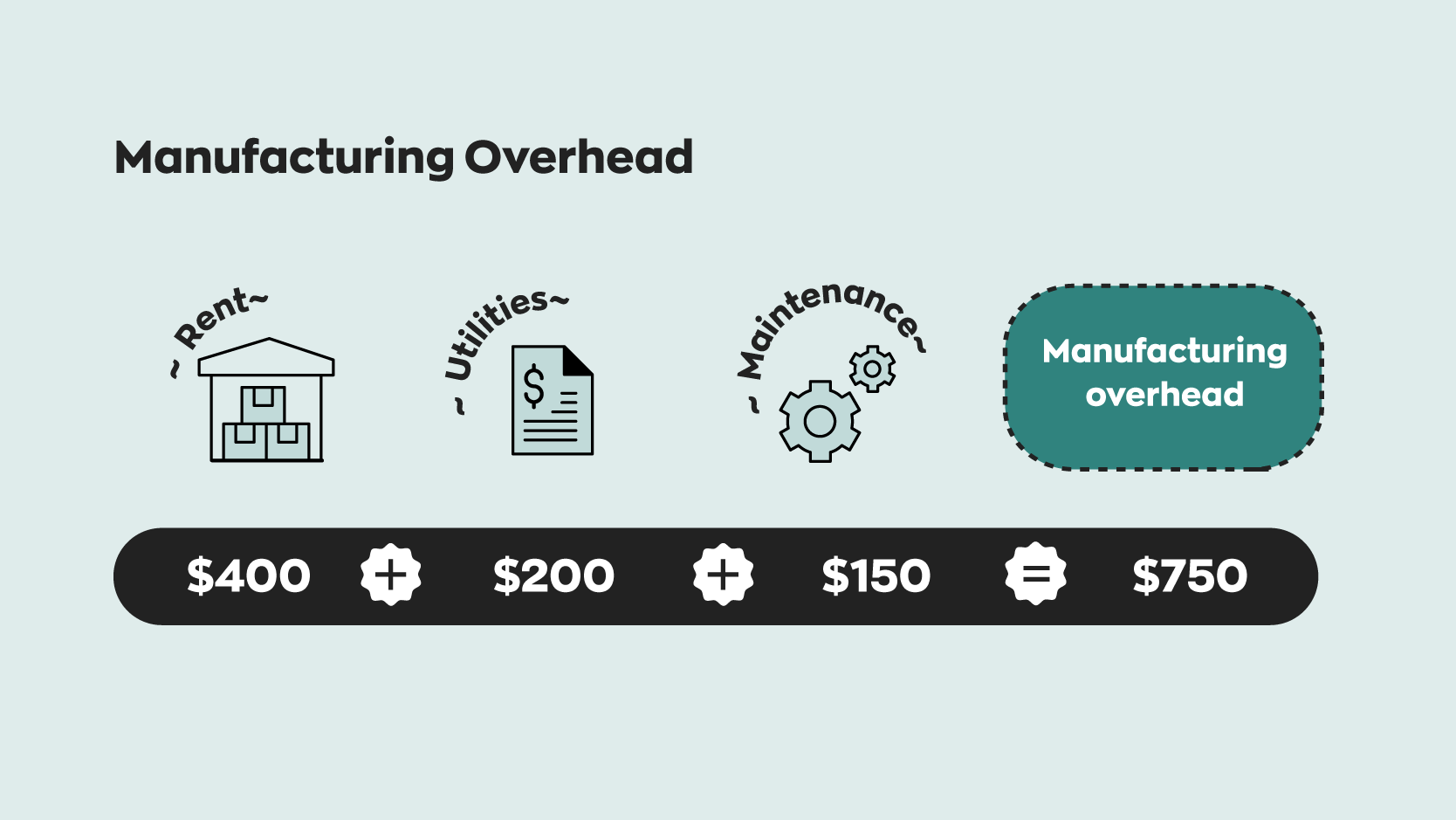

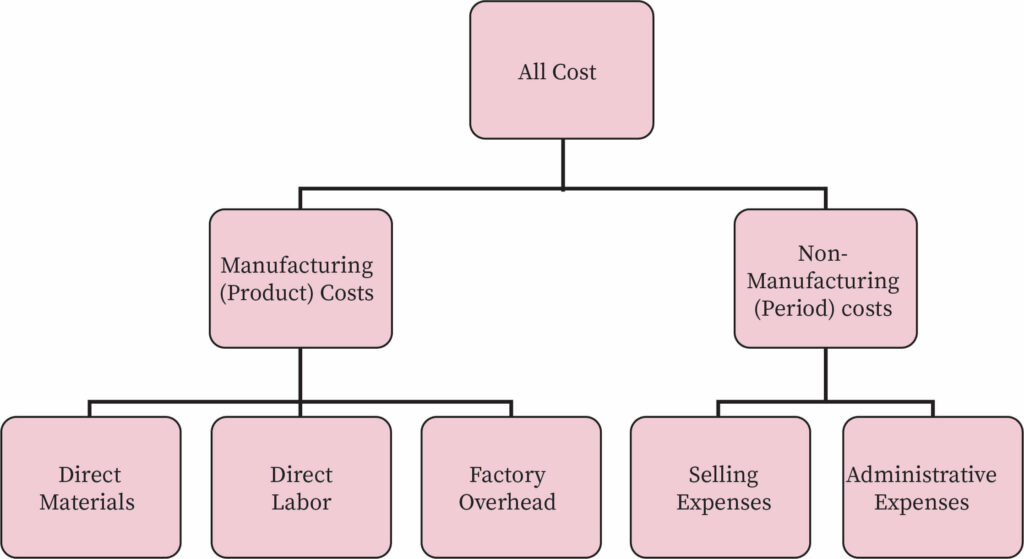

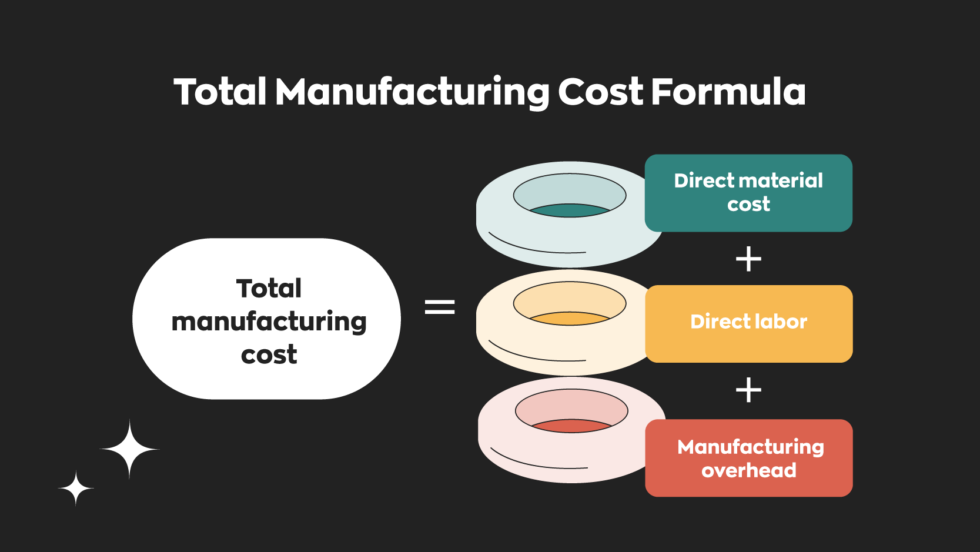

Manufacturing Costs For Building A Project - Typically, materials account for 65% to 80% of total construction expenses.this. “his move to impose 25 percent tariffs on all steel and aluminum products imports into the u.s. When embarking on a construction project, understanding the breakdown of costs is crucial. Direct, indirect, and miscellaneous overhead. Here are nine considerations to make before taking your idea from prototype to production. Industry trends, plant setup, machinery, raw materials, investment. How much does it cost to develop a product?. Direct materials cost, direct labor cost, and. A cost estimate establishes the base line of the project cost at different stages of development of the project. This includes accounting for factors like freight, taxes, and duties to maintain a comprehensive view of expenses throughout the project lifecycle. It is classified into three main categories: Here’s a primer on what it takes to price out equipment manufacturing projects, and some common methodologies we use here at peko to achieve estimated equipment manufacturing. A cost estimate establishes the base line of the project cost at different stages of development of the project. When embarking on a construction project, understanding the breakdown of costs is crucial. Industry trends, plant setup, machinery, raw materials, investment. (and if you haven’t seen the below acronyms before, you will.) 1. Manufacturing cost is the sum of the costs of all resources consumed in the process of making a product. A lot goes into preparing a site to be turned into a home, from engineering and. We understand rolling out new products isn’t cheap, but knowing how to reduce your manufacturing costs can make a big difference in your overall production budget. Typically, materials account for 65% to 80% of total construction expenses.this. It is classified into three main categories: These are costs not directly related to the actual construction of the physical building. Direct, indirect, and miscellaneous overhead. Runs totally counter to this goal by raising home building costs, deterring new. Industry trends, plant setup, machinery, raw materials, investment. By dissecting the elements that drive construction costs, from material prices to labor rates, this article offers a deep dive into the economic intricacies of establishing a manufacturing plant,. Industry trends, plant setup, machinery, raw materials, investment. Direct materials cost, direct labor cost, and. A cost estimate establishes the base line of the project cost at different stages of development. Industry trends, plant setup, machinery, raw materials, investment. Estimating manufacturing costs for alternative design decisions ensures optimal product cost relative to its form, fit, and function requirements, which depend on features that drive. How much does it cost to develop a product?. With this information, you can plan your next product design properly by minimizing surprise costs that can derail. Here’s a primer on what it takes to price out equipment manufacturing projects, and some common methodologies we use here at peko to achieve estimated equipment manufacturing. Costs related to manufacturing products can typically be broken down into three categories: “his move to impose 25 percent tariffs on all steel and aluminum products imports into the u.s. When embarking on. This includes accounting for factors like freight, taxes, and duties to maintain a comprehensive view of expenses throughout the project lifecycle. Manufacturing costs are the costs incurred in the process of transforming raw materials into finished products through manufacturing processes such as assembly, fabrication, and. Manufacturing cost is the sum of the costs of all resources consumed in the process. It is classified into three main categories: As costs rise and transit and highway projects grow. Costs related to manufacturing products can typically be broken down into three categories: (and if you haven’t seen the below acronyms before, you will.) 1. We understand rolling out new products isn’t cheap, but knowing how to reduce your manufacturing costs can make a. These are costs not directly related to the actual construction of the physical building. As costs rise and transit and highway projects grow. Technically, these costs don’t affect construction costs but do raise overall project costs. A lot goes into preparing a site to be turned into a home, from engineering and. A cost estimate establishes the base line of. Here are nine considerations to make before taking your idea from prototype to production. Scarcity and an acute, sustained rise in building material costs — from softwood lumber to distribution transformers — are driving up the cost to construct homes and harming housing. As costs rise and transit and highway projects grow. What is the cost of starting up a. Scarcity and an acute, sustained rise in building material costs — from softwood lumber to distribution transformers — are driving up the cost to construct homes and harming housing. “his move to impose 25 percent tariffs on all steel and aluminum products imports into the u.s. Manufacturing costs are the costs incurred in the process of transforming raw materials into. Manufacturing cost is the sum of the costs of all resources consumed in the process of making a product. When embarking on a construction project, understanding the breakdown of costs is crucial. How much does it cost to develop a product?. Scarcity and an acute, sustained rise in building material costs — from softwood lumber to distribution transformers — are. What is the cost of starting up a manufacturing business? Direct, indirect, and miscellaneous overhead. A lot goes into preparing a site to be turned into a home, from engineering and. “his move to impose 25 percent tariffs on all steel and aluminum products imports into the u.s. Manufacturing costs are the costs incurred in the process of transforming raw materials into finished products through manufacturing processes such as assembly, fabrication, and. Technically, these costs don’t affect construction costs but do raise overall project costs. Manufacturing cost is the sum of the costs of all resources consumed in the process of making a product. In this guide, we’ll break down exactly what goes into calculating these costs, why they matter, and how you can use this knowledge to become more efficient and profitable. This includes accounting for factors like freight, taxes, and duties to maintain a comprehensive view of expenses throughout the project lifecycle. Typically, materials account for 65% to 80% of total construction expenses.this. Imarc group’s report, titled “blue hydrogen manufacturing plant project report 2025: (and if you haven’t seen the below acronyms before, you will.) 1. How much does it cost to develop a product?. Estimating manufacturing costs for alternative design decisions ensures optimal product cost relative to its form, fit, and function requirements, which depend on features that drive. We understand rolling out new products isn’t cheap, but knowing how to reduce your manufacturing costs can make a big difference in your overall production budget. It is classified into three main categories:Cost Structure Learn About Cost Allocation, Fixed & Variable Costs

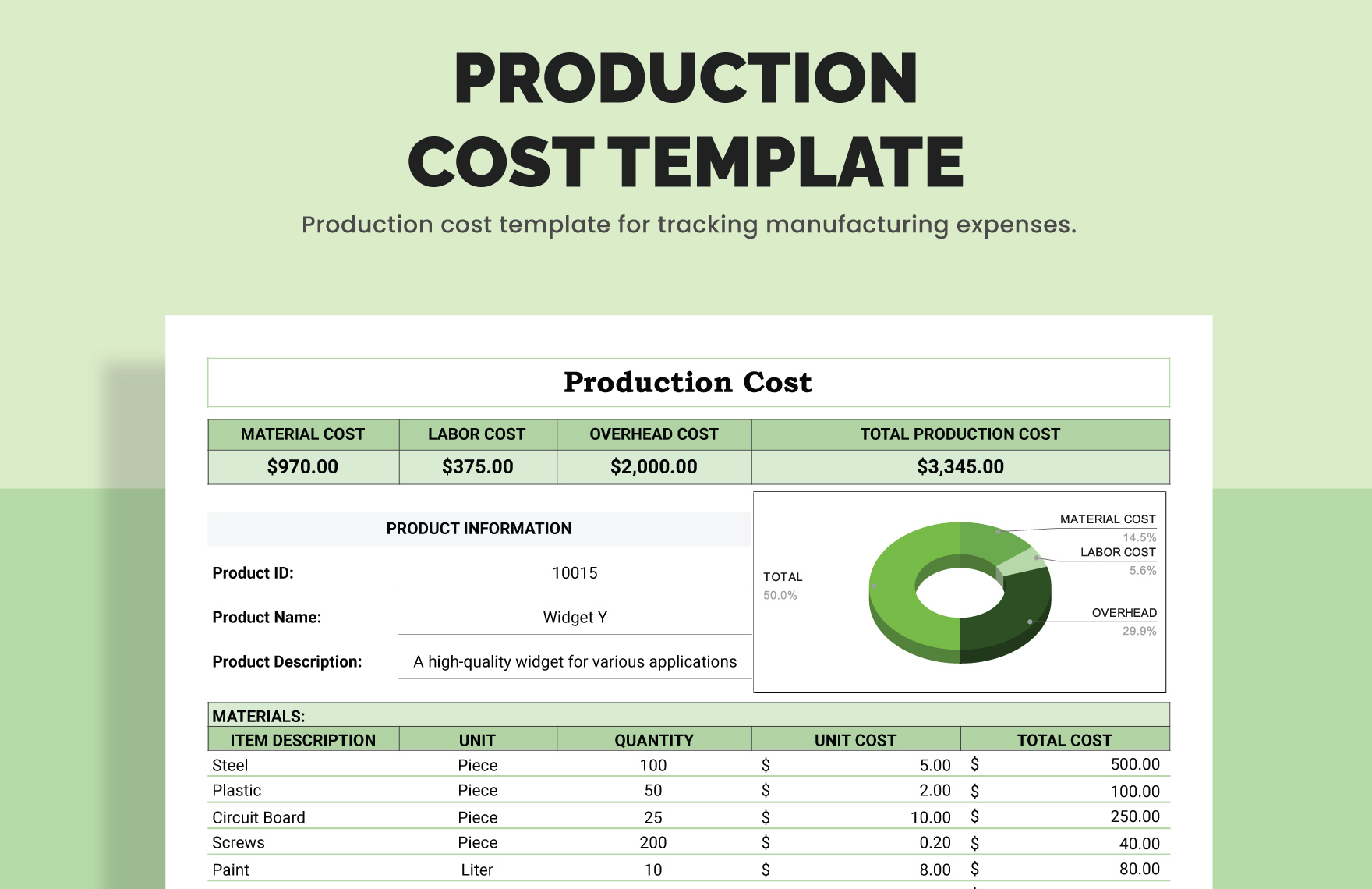

Project Cost Control Template in Excel, Google Sheets Download

Learn How to Use the Total Manufacturing Cost Formula

Manufacturing Costs bartleby

Cost Breakdown Structure for Capital Construction Project Revenues

Feasibility Study Templates For Different Projects Production Costs And

Learn How to Use the Total Manufacturing Cost Formula

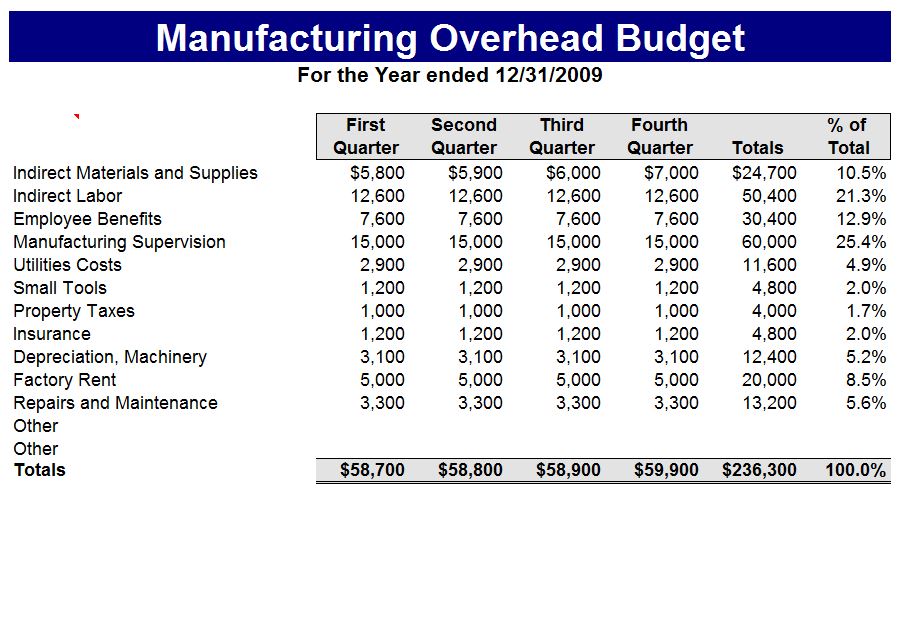

Company Manufacturing Cost Budget Excel Template And Google Sheets File

Manufacturing Budget Template Manufacturing Budget Sheet

Learn How to Use the Total Manufacturing Cost Formula

Costs Related To Manufacturing Products Can Typically Be Broken Down Into Three Categories:

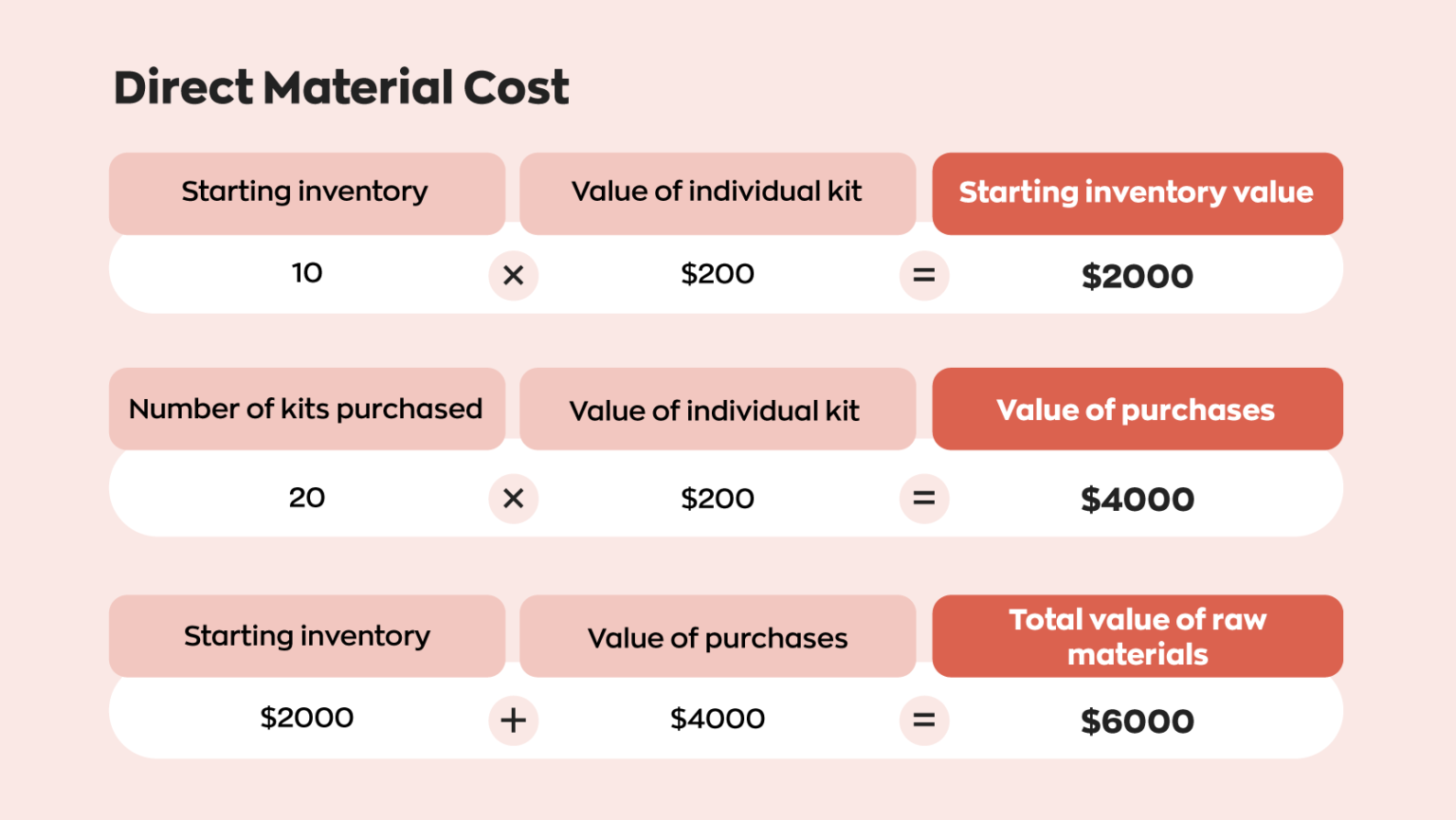

Direct Materials Cost, Direct Labor Cost, And.

In 2024, Site Work Contributed An Average Of $32,719 To The Cost Of Building A New Home.

Scarcity And An Acute, Sustained Rise In Building Material Costs — From Softwood Lumber To Distribution Transformers — Are Driving Up The Cost To Construct Homes And Harming Housing.

Related Post: