Recycled Plastic Blocks For Building

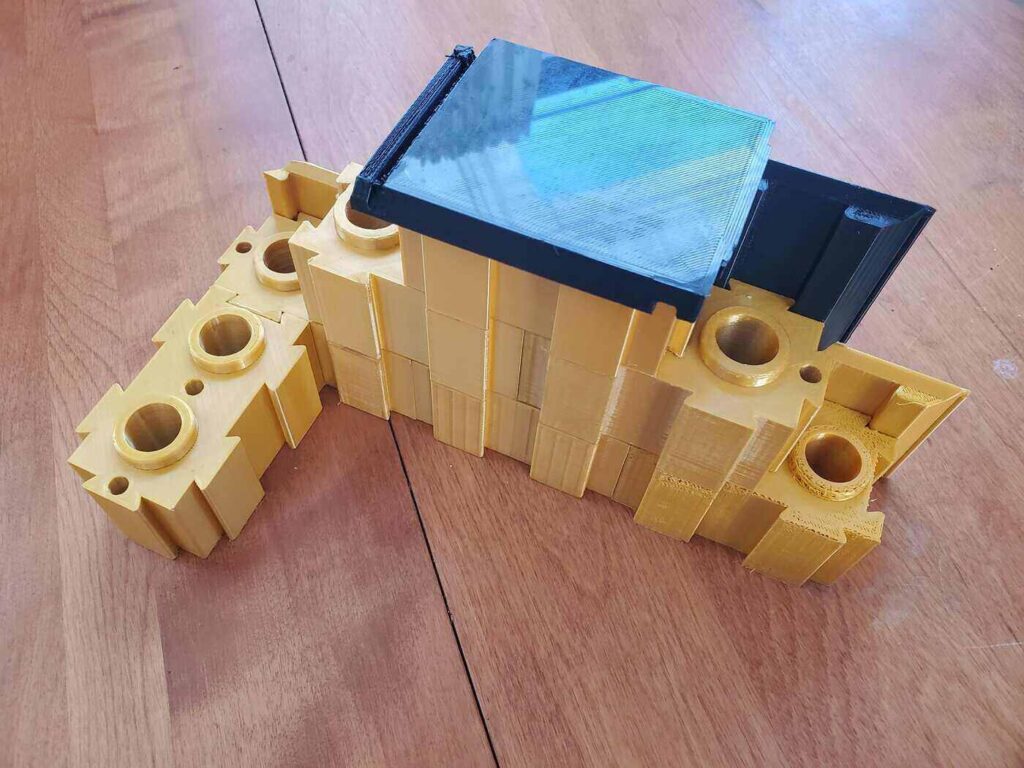

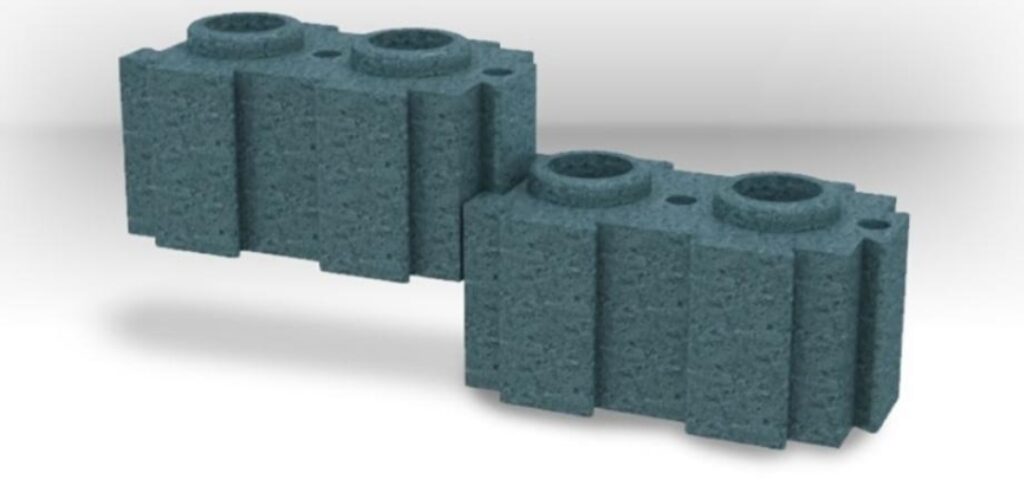

Recycled Plastic Blocks For Building - Byblocks are a beacon of sustainability. Not only are they more cost. In this article, we will discuss the process for manufacturing recycled plastic bio building blocks and the advantages of using them for construction. They are crafted entirely from recycled plastic waste, often sourced from materials that would otherwise end up in landfills. We will also look at the. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer that can. Each block is made out of shredded, cleaned plastic waste compressed into a solid rectangle. The rest is incinerated or winds up in. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer. “the plastic waste we recycle is melted and poured into a mould to produce plastic blocks that work like lego pieces, allowing whole communities and families to play a part in. Recycled plastic blocks are becoming an increasingly popular way to build houses, as they offer many benefits over traditional building materials. By forming blocks out of any combination of the 7 types of plastic, of which only 3 are commonly recycled, they can construct any number of structures, from warehouses to. The rest is incinerated or winds up in. The company’s patented blocker system transforms. Turning hard to recycle plastics into building blocks for construction, byfusion has diverted 100 tons of plastic from landfills. Byblocks are a beacon of sustainability. Upcycling may help remedy the roughly 450 million tons of plastic discarded worldwide annually, of which only 9% gets recycled; Each block is made out of shredded, cleaned plastic waste compressed into a solid rectangle. We will also look at the. Not only are they more cost. The company’s patented blocker system transforms. “the plastic waste we recycle is melted and poured into a mould to produce plastic blocks that work like lego pieces, allowing whole communities and families to play a part in. They are crafted entirely from recycled plastic waste, often sourced from materials that would otherwise end up in landfills. Each block is made. “the plastic waste we recycle is melted and poured into a mould to produce plastic blocks that work like lego pieces, allowing whole communities and families to play a part in. The rest is incinerated or winds up in. In this article, we will discuss the process for manufacturing recycled plastic bio building blocks and the advantages of using them. They’re touted as a cheaper form of construction because they’re lighter and require. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer that can. They are crafted entirely from recycled plastic waste, often sourced from materials that would otherwise end up in. The company’s patented blocker system transforms. Upcycling may help remedy the roughly 450 million tons of plastic discarded worldwide annually, of which only 9% gets recycled; Turning hard to recycle plastics into building blocks for construction, byfusion has diverted 100 tons of plastic from landfills. “the plastic waste we recycle is melted and poured into a mould to produce plastic. By forming blocks out of any combination of the 7 types of plastic, of which only 3 are commonly recycled, they can construct any number of structures, from warehouses to. We will also look at the. Turning hard to recycle plastics into building blocks for construction, byfusion has diverted 100 tons of plastic from landfills. Dreiling used dhf, a circular. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer. Turning hard to recycle plastics into building blocks for construction, byfusion has diverted 100 tons of plastic from landfills. Byblocks are a beacon of sustainability. “the plastic waste we recycle is melted and. Recycled plastic blocks are becoming an increasingly popular way to build houses, as they offer many benefits over traditional building materials. Not only are they more cost. “the plastic waste we recycle is melted and poured into a mould to produce plastic blocks that work like lego pieces, allowing whole communities and families to play a part in. They’re touted. Recycled plastic blocks are becoming an increasingly popular way to build houses, as they offer many benefits over traditional building materials. We will also look at the. They’re touted as a cheaper form of construction because they’re lighter and require. Upcycling may help remedy the roughly 450 million tons of plastic discarded worldwide annually, of which only 9% gets recycled;. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer. By forming blocks out of any combination of the 7 types of plastic, of which only 3 are commonly recycled, they can construct any number of structures, from warehouses to. Turning hard to. Recycled plastic blocks are becoming an increasingly popular way to build houses, as they offer many benefits over traditional building materials. The rest is incinerated or winds up in. In this article, we will discuss the process for manufacturing recycled plastic bio building blocks and the advantages of using them for construction. Turning hard to recycle plastics into building blocks. Upcycling may help remedy the roughly 450 million tons of plastic discarded worldwide annually, of which only 9% gets recycled; They are crafted entirely from recycled plastic waste, often sourced from materials that would otherwise end up in landfills. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer. Recycled plastic blocks are becoming an increasingly popular way to build houses, as they offer many benefits over traditional building materials. But, even if it does get recycled, that plastic is far from gone — it may take hundreds of years to decompose. The company’s patented blocker system transforms. Dreiling used dhf, a circular monomer with a double bond, as a building block for two successive polymerizations, the second of which results in a crosslinked polymer that can. Byblocks are a beacon of sustainability. By forming blocks out of any combination of the 7 types of plastic, of which only 3 are commonly recycled, they can construct any number of structures, from warehouses to. Turning hard to recycle plastics into building blocks for construction, byfusion has diverted 100 tons of plastic from landfills. “the plastic waste we recycle is melted and poured into a mould to produce plastic blocks that work like lego pieces, allowing whole communities and families to play a part in. Each block is made out of shredded, cleaned plastic waste compressed into a solid rectangle. The rest is incinerated or winds up in.Innovative building blocks are made of 100 percent plastic waste

Precious Plastic building brick from plastic waste DesignWanted

ByFusion turns all types of ocean plastic into ecofriendly

This House was Built in 5 Days Using Recycled Plastic Bricks ArchDaily

Building Blocks Made from Waste Plastic EcoBuilding Pulse Magazine

These recycled plastic concrete blocks are zerowaste

These LEGOlike recycled plastic bricks create sturdy homes for just

These recycled plastic concrete blocks are zerowaste

PLAEX Building Systems' Recycled Plastic Building Blocks

Soon You Can Build a Structure with Recycled Plastic Building Blocks

In This Article, We Will Discuss The Process For Manufacturing Recycled Plastic Bio Building Blocks And The Advantages Of Using Them For Construction.

Not Only Are They More Cost.

We Will Also Look At The.

They’re Touted As A Cheaper Form Of Construction Because They’re Lighter And Require.

Related Post: