Should Normal Exposure Be Higher For Resin Build Plate Adhesion

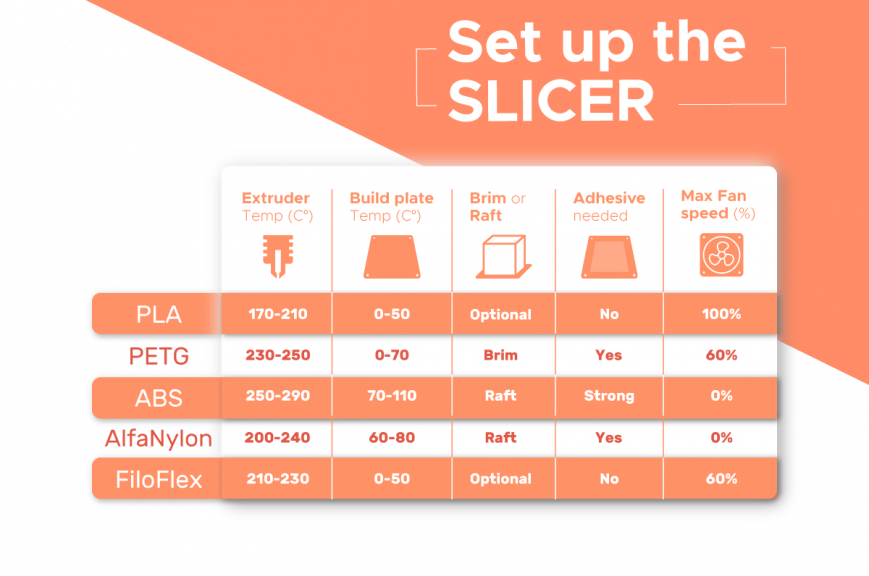

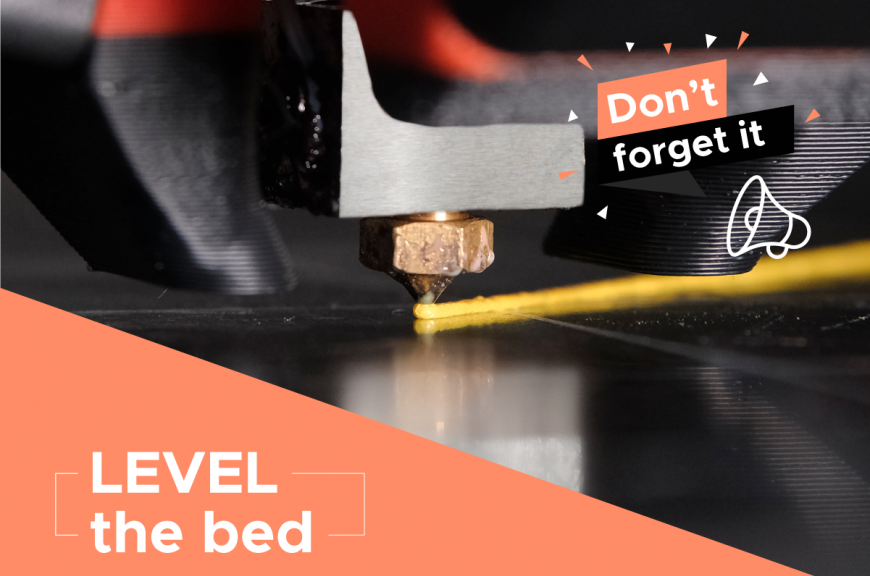

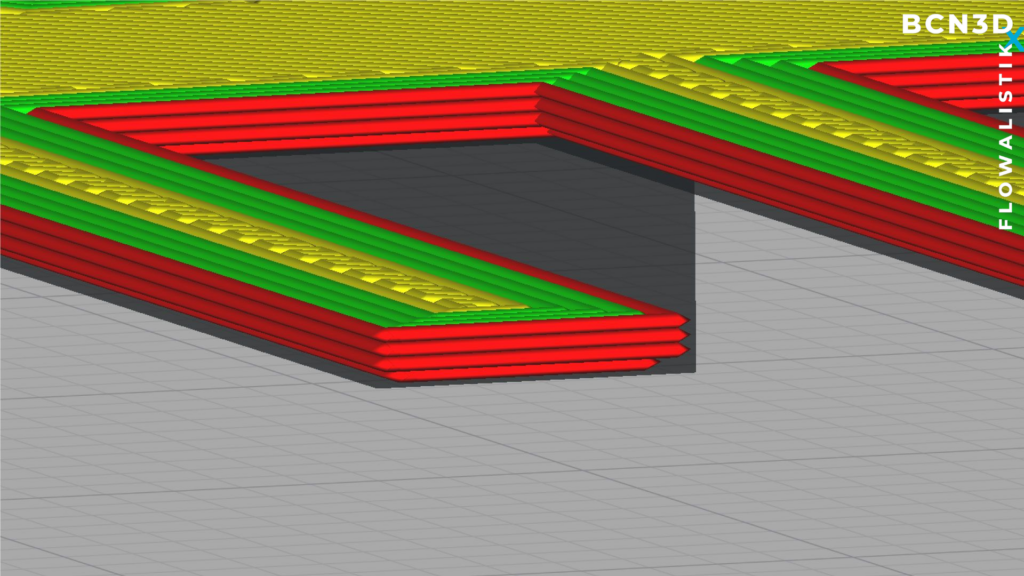

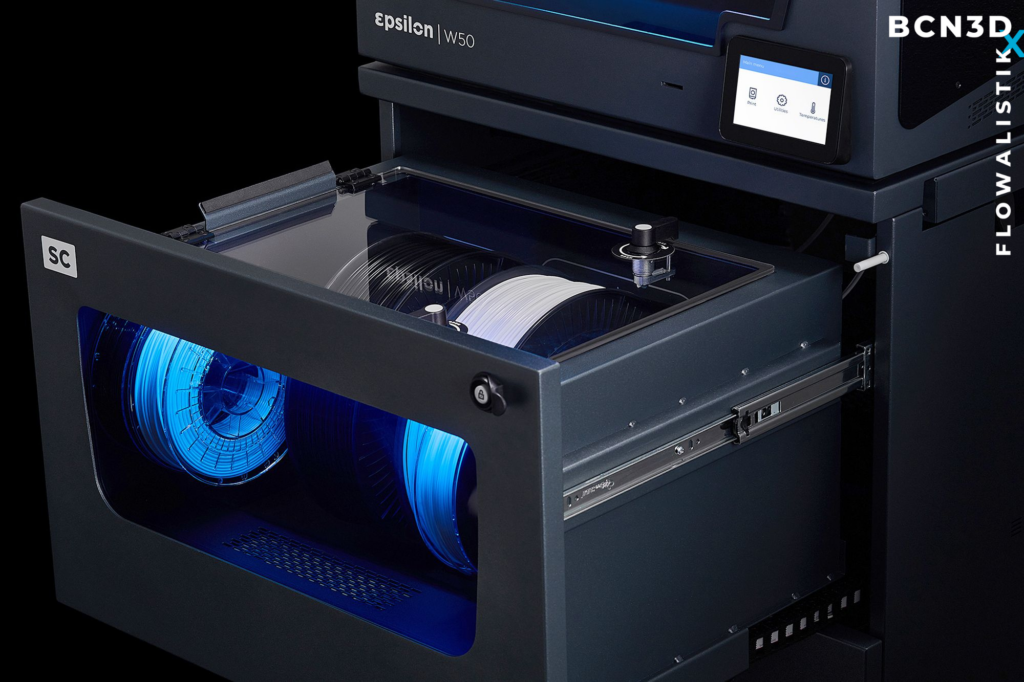

Should Normal Exposure Be Higher For Resin Build Plate Adhesion - Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. You can correct that by. Wrong exposure time is the major reason why resin 3d prints fail or are imprecise. All remaining 16 layers of your raft will only be cured with normal layer exposures! It is quite common to over cure initial layers of 3d printed object to have better adhesion to build plate. So, 8s is a little bit overexposed. Even with 55 the bottom of the validation matrix. However, this would result in visible layer lines and thicker sections at. Underexposing each layer results in serious loss and miniaturization of intricate details, delamination, weak. The initial layers need extra exposure to adhere strongly to the build plate. It is quite common to over cure initial layers of 3d printed object to have better adhesion to build plate. Underexposing each layer results in serious loss and miniaturization of intricate details, delamination, weak. Even with 55 the bottom of the validation matrix. Wrong exposure time is the major reason why resin 3d prints fail or are imprecise. Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. In order to improve build plate adhesion for pla, abs, and petg, you should level your build plate, optimize your build plate temperature, use an adhesive on your build. The edges of the layerlock sla sheet need to be flush against the build plate. This minimizes the chances of resin and cleaning solvents from seeping into the build. Make sure your build plate is level; But only a little bit overexposed, even though it's three times as long as the profile that other people claim to get good prints with. Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. In fact, all the timings elegoo. You do not need to use any glue or any other adhesion modifier to increase your build plate adhesion. So, 8s is a little bit overexposed. You can correct that. Make sure your build plate is level; Underexposing each layer results in serious loss and miniaturization of intricate details, delamination, weak. Wrong exposure time is the major reason why resin 3d prints fail or are imprecise. This happens because of your high bottom layer exposure rate, the uv light bleeds into the surrounding resin which also cures creating the elephant's. Underexposing each layer results in serious loss and miniaturization of intricate details, delamination, weak. This minimizes the chances of resin and cleaning solvents from seeping into the build. Make sure your build plate is level; Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. The. This happens because of your high bottom layer exposure rate, the uv light bleeds into the surrounding resin which also cures creating the elephant's foot. Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. All remaining 16 layers of your raft will only be cured. Make sure your build plate is level; Wrong exposure time is the major reason why resin 3d prints fail or are imprecise. In fact, all the timings elegoo. You can correct that by. Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. Underexposing each layer results in serious loss and miniaturization of intricate details, delamination, weak. In fact, all the timings elegoo. The edges of the layerlock sla sheet need to be flush against the build plate. You do not need to use any glue or any other adhesion modifier to increase your build plate adhesion. Even with 55 the bottom of. Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. This minimizes the chances of resin and cleaning solvents from seeping into the build. So, 8s is a little bit overexposed. Make sure your build plate is level; In fact, all the timings elegoo. Make sure your build plate is level; However, this would result in visible layer lines and thicker sections at. So, 8s is a little bit overexposed. The edges of the layerlock sla sheet need to be flush against the build plate. In order to improve build plate adhesion for pla, abs, and petg, you should level your build plate, optimize. The initial layers need extra exposure to adhere strongly to the build plate. You can correct that by. In order to improve build plate adhesion for pla, abs, and petg, you should level your build plate, optimize your build plate temperature, use an adhesive on your build. However, this would result in visible layer lines and thicker sections at. In. But only a little bit overexposed, even though it's three times as long as the profile that other people claim to get good prints with. However, this would result in visible layer lines and thicker sections at. This minimizes the chances of resin and cleaning solvents from seeping into the build. In order to improve build plate adhesion for pla,. Everything i’ve read seems like it should be much lower bottom exposure and regular exposure but prints just won’t adhere to the build plate. However, this would result in visible layer lines and thicker sections at. The edges of the layerlock sla sheet need to be flush against the build plate. This minimizes the chances of resin and cleaning solvents from seeping into the build. All remaining 16 layers of your raft will only be cured with normal layer exposures! In order to improve build plate adhesion for pla, abs, and petg, you should level your build plate, optimize your build plate temperature, use an adhesive on your build. So, 8s is a little bit overexposed. In fact, all the timings elegoo. But only a little bit overexposed, even though it's three times as long as the profile that other people claim to get good prints with. The initial layers need extra exposure to adhere strongly to the build plate. This happens because of your high bottom layer exposure rate, the uv light bleeds into the surrounding resin which also cures creating the elephant's foot. Underexposing each layer results in serious loss and miniaturization of intricate details, delamination, weak. You do not need to use any glue or any other adhesion modifier to increase your build plate adhesion. Even with 55 the bottom of the validation matrix.BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

3d printing build plate adhesion

Build plate adhesion settings

Cura Build Plate Adhesion Types & Settings Guide MeaD MaDe

3d printing build plate adhesion

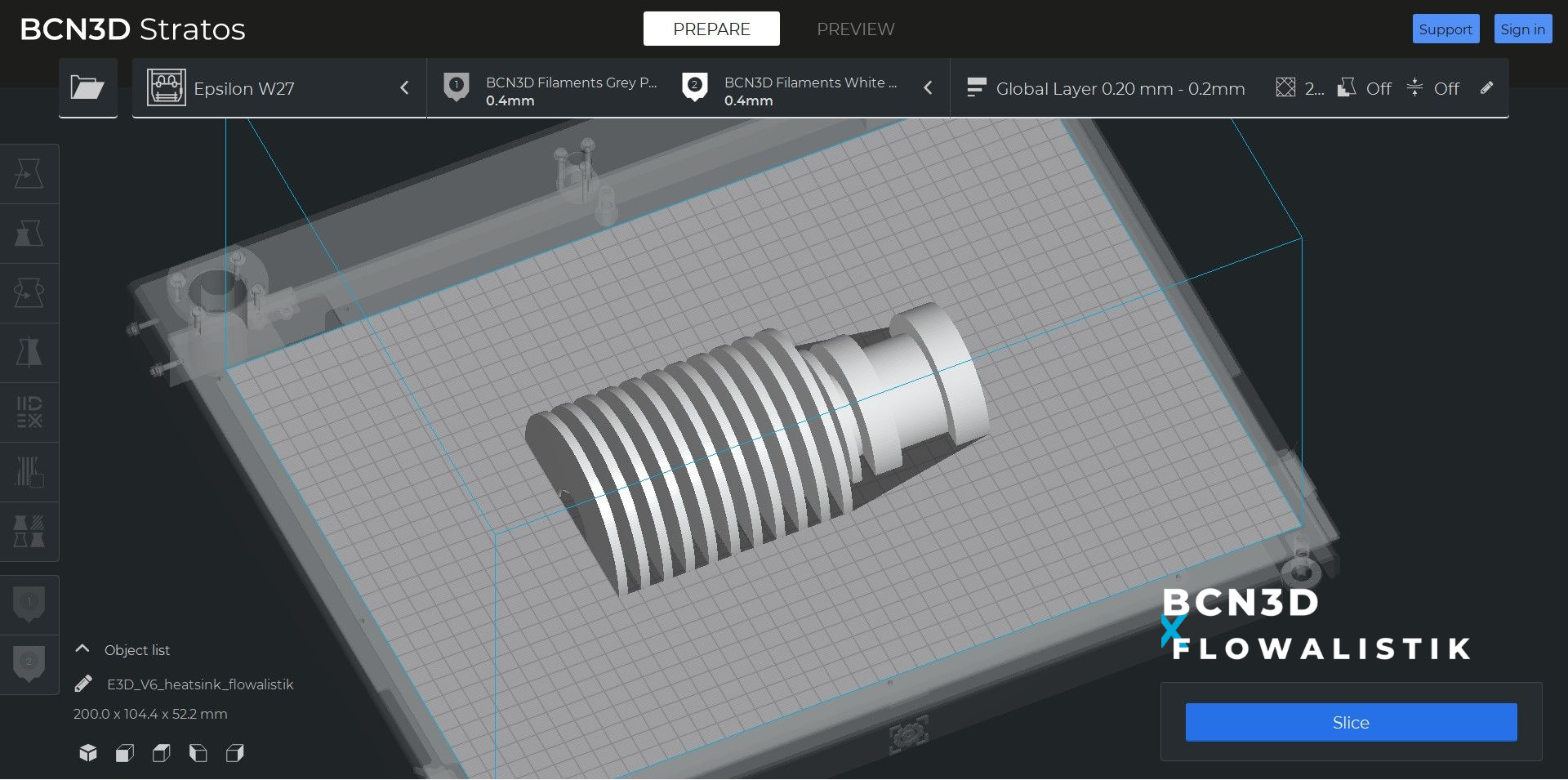

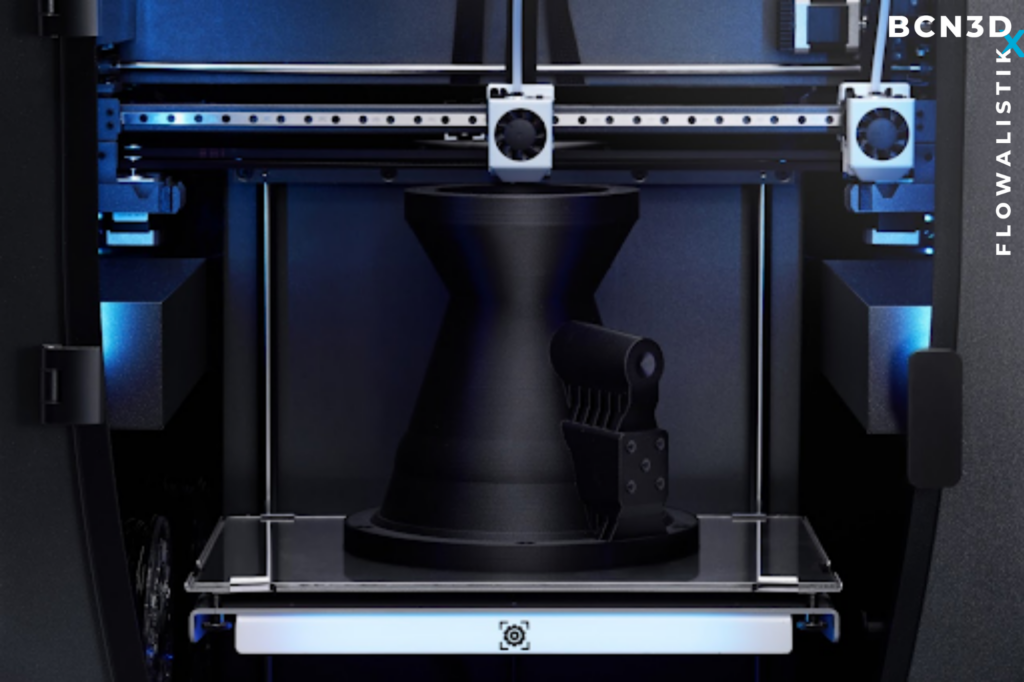

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

increasing build plate adhesion r/resinprinting

BCN3D Slicing Guide 6 Top tips for build plate adhesion proficiency

3d printing build plate adhesion

It Is Quite Common To Over Cure Initial Layers Of 3D Printed Object To Have Better Adhesion To Build Plate.

Wrong Exposure Time Is The Major Reason Why Resin 3D Prints Fail Or Are Imprecise.

Make Sure Your Build Plate Is Level;

You Can Correct That By.

Related Post: