Truck Wont Build Air Past 60 Psi

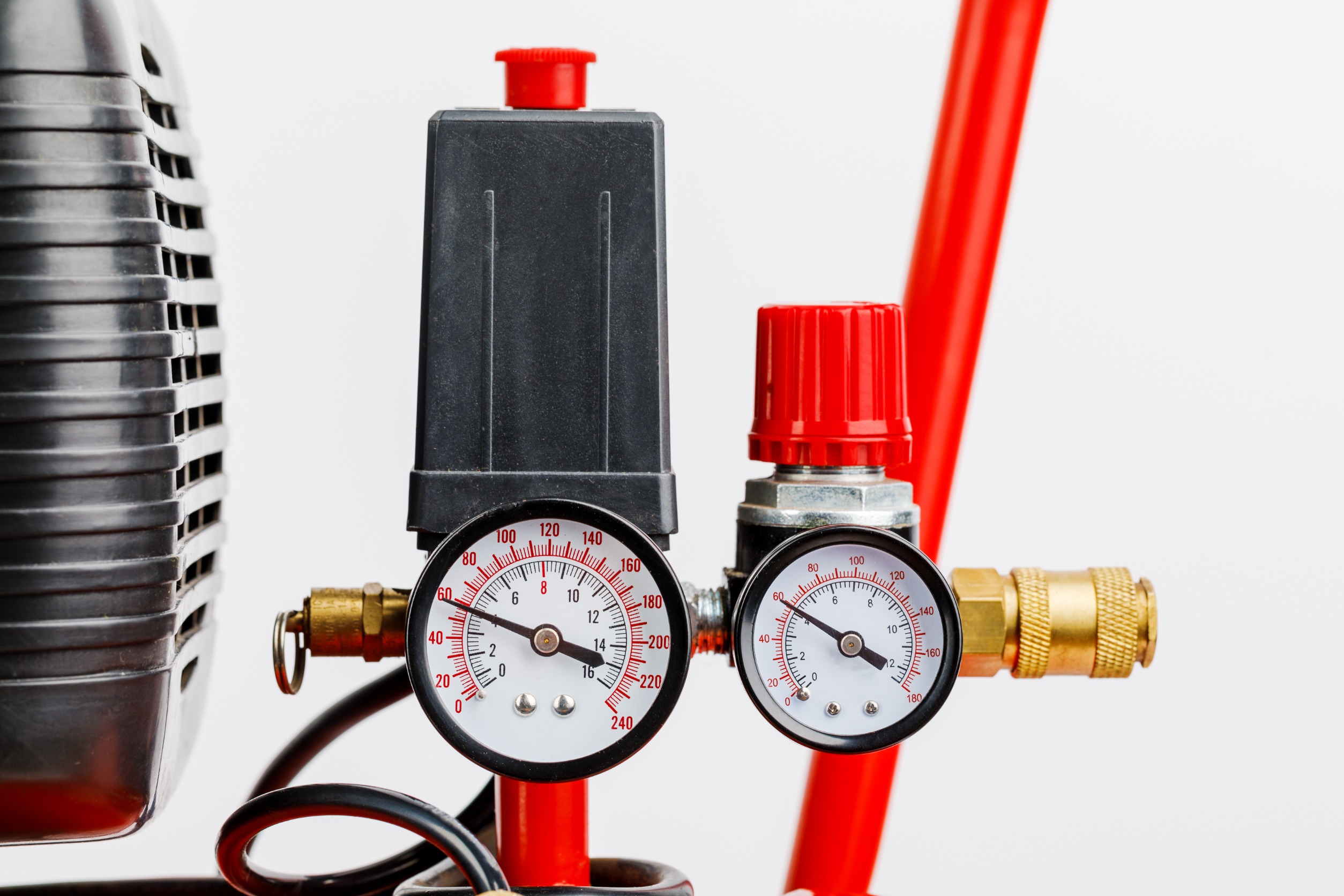

Truck Wont Build Air Past 60 Psi - It will not build pressure if the exhaust is open, but rather pass the air through. The most obvious symptoms of a bad air governor are the safety valve triggering and the truck taking too long to build pressure. Up to $9 cash back best way i found to confirm this is to remove the discharge line from the compressor (when engine is cooled down) and supply air pressure to system with shop air. Find out if it's leaking air somewhere or if the compressor stops working when it hits 60. When my tanks start filling up, 60 psi is about the point where it starts filling the air. Easiest way for a shade tree mechanic, hook the output of the compressor to an air tank (portable tire inflation tank) take the governor off. My vote is that you either have an open in your discharge line, massive leak, or mechanical. Remove the compressor discharge at the compressor and apply shop air to the line and see if you have a massive leak after the air dryer or somewhere else to cause the low. Make sure the truck is somewhere above freezing to rule out ice. There are several components that all cause about the same. I have had the unloader valve in the compressor go bad, but not very often. When my tanks start filling up, 60 psi is about the point where it starts filling the air. Start truck, is air leaking out the. Make sure the truck is somewhere above freezing to rule out ice. And here are some more signs. Starting your day only to find your truck won’t build air pressure can be frustrating, but don’t let it derail your schedule. Easiest way for a shade tree mechanic, hook the output of the compressor to an air tank (portable tire inflation tank) take the governor off. 1) deadhead the compressor with a gauge and no air in the tanks to see if that's really a problem. Here are some practical steps to troubleshoot and address. Up to $9 cash back best way i found to confirm this is to remove the discharge line from the compressor (when engine is cooled down) and supply air pressure to system with shop air. Remove the compressor discharge at the compressor and apply shop air to the line and see if you have a massive leak after the air dryer or somewhere else to cause the low. The shop however hooked the shop airline to the hose from. My vote is that you either have an open in your discharge line, massive leak, or. Remove the compressor discharge at the compressor and apply shop air to the line and see if you have a massive leak after the air dryer or somewhere else to cause the low. The most obvious symptoms of a bad air governor are the safety valve triggering and the truck taking too long to build pressure. They are easy to. Pulled off inlet at dyer from the compressor and have pretty decent air pressure, but no gauge to check. And here are some more signs. The shop however hooked the shop airline to the hose from. Find out if it's leaking air somewhere or if the compressor stops working when it hits 60. They are easy to replace, just a. Make sure the truck is somewhere above freezing to rule out ice. If your semi truck is taking longer than usual to build air pressure or if it’s not building air pressure at all, you may. Pulled off inlet at dyer from the compressor and have pretty decent air pressure, but no gauge to check. This will only be leaking. Find out if it's leaking air somewhere or if the compressor stops working when it hits 60. Easiest way for a shade tree mechanic, hook the output of the compressor to an air tank (portable tire inflation tank) take the governor off. My vote is that you either have an open in your discharge line, massive leak, or mechanical. Replaced. They are easy to replace, just a. Once it hits 60 psi, it. It will not build pressure if the exhaust is open, but rather pass the air through. The shop however hooked the shop airline to the hose from. Here are some practical steps to troubleshoot and address. Make sure the truck is somewhere above freezing to rule out ice. This will only be leaking with the truck running so it will be hard to hear. My vote is that you either have an open in your discharge line, massive leak, or mechanical. Once it hits 60 psi, it. Replaced air compressor, dryer and leveler but secondary air. Up to $9 cash back best way i found to confirm this is to remove the discharge line from the compressor (when engine is cooled down) and supply air pressure to system with shop air. Start truck, is air leaking out the. Starting your day only to find your truck won’t build air pressure can be frustrating, but don’t let. Find out if it's leaking air somewhere or if the compressor stops working when it hits 60. The shop however hooked the shop airline to the hose from. Here are some practical steps to troubleshoot and address. I already checked all air lines and dont see or hear anything leaking. There is a check valve in there that can fail. There is a bulkhead inside to separate the back half of the air tank. If your semi truck is taking longer than usual to build air pressure or if it’s not building air pressure at all, you may. Sometimes trying to figure out why a truck won't build air is tricky, especially when you can't hear air leaking. Start truck,. You can try to soak. The shop however hooked the shop airline to the hose from. Here are some practical steps to troubleshoot and address. Starting your day only to find your truck won’t build air pressure can be frustrating, but don’t let it derail your schedule. After the air dryer, the air goes to the front half of the wet tank. When my tanks start filling up, 60 psi is about the point where it starts filling the air. The most obvious symptoms of a bad air governor are the safety valve triggering and the truck taking too long to build pressure. There is a bulkhead inside to separate the back half of the air tank. Make sure the truck is somewhere above freezing to rule out ice. My vote is that you either have an open in your discharge line, massive leak, or mechanical. Sometimes trying to figure out why a truck won't build air is tricky, especially when you can't hear air leaking. Replaced air compressor, dryer and leveler but secondary air won't build pass 75 while primary won't go pass 100. Up to $9 cash back more than likely the air compressor discharge line is leaking somewhere. This will only be leaking with the truck running so it will be hard to hear. Once it hits 60 psi, it. Find out if it's leaking air somewhere or if the compressor stops working when it hits 60.Semi Truck Won'T Build Air Pressure • The Truck How

Truck tractor air compressor air dryer bypass no air pressure does not

Semi Truck Won'T Build Air Pressure • The Truck How

How to repair fix air compressor not building pressure easy fix YouTube

Help! My air compressor won’t build pressure past 20 PSI YouTube

How To Fix Air Compressor Not Building Pressure. YouTube

Semi Truck Won'T Build Air Pressure • The Truck How

Why Air Pressure not building up on Semi Truck? (Do this before

Truck Doesn't Build Air air mechanic howto troubleshooting YouTube

Mack _ Cummins air compressor won’t build air pressure YouTube

I Already Checked All Air Lines And Dont See Or Hear Anything Leaking.

There Are Several Components That All Cause About The Same.

They Are Easy To Replace, Just A.

Remove The Compressor Discharge At The Compressor And Apply Shop Air To The Line And See If You Have A Massive Leak After The Air Dryer Or Somewhere Else To Cause The Low.

Related Post: