When Would A Builder Most Likely Use Marine Grade Plywood

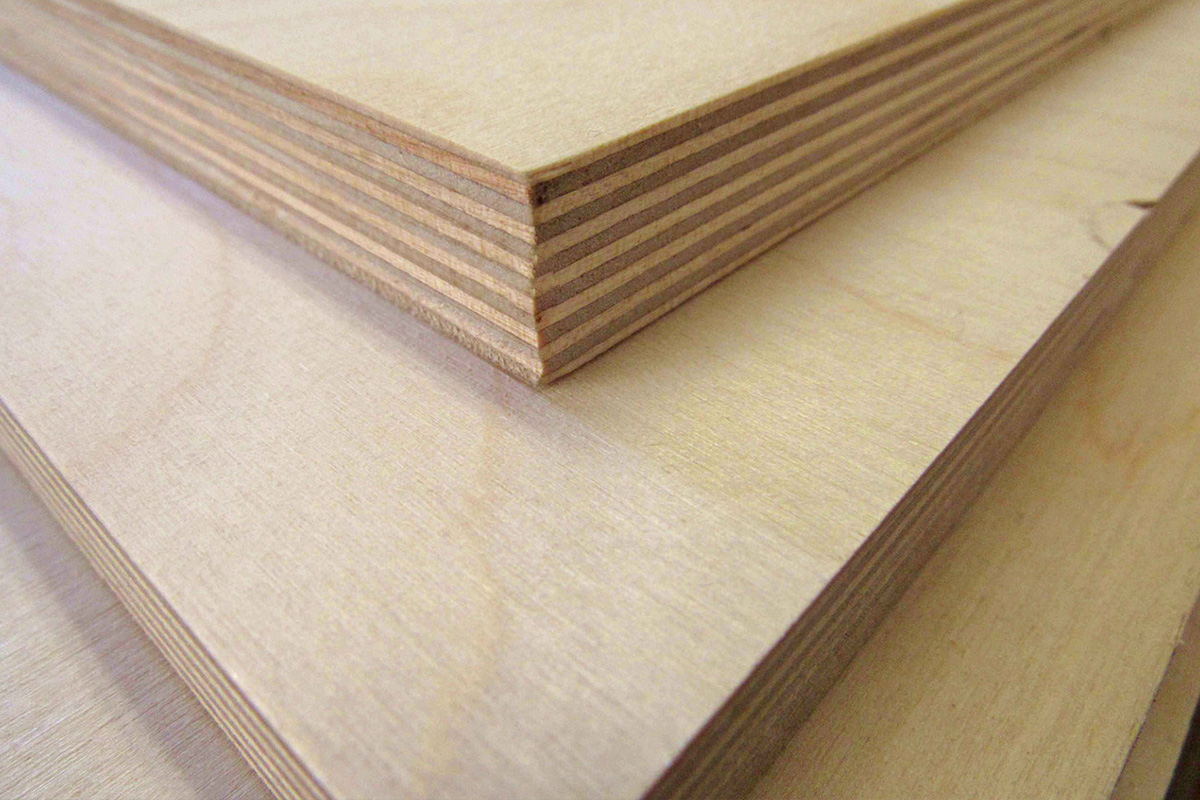

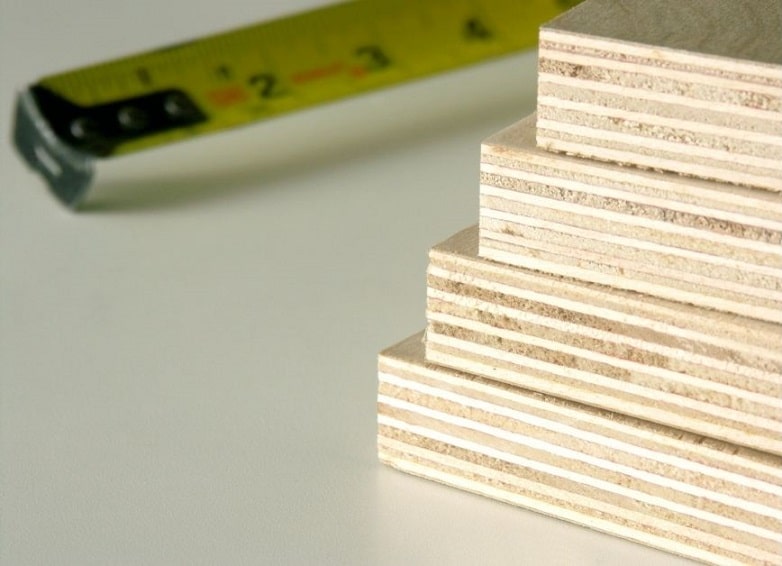

When Would A Builder Most Likely Use Marine Grade Plywood - This makes marine ply grade key for projects in wet areas, like boat. In today’s modern world, the importance of marine grade plywood is still the same and can be used for building furniture of your patio and outdoor projects. When would a builder most likely use marinegrade plywood? Exterior plywood, on the other hand, is plywood designed for outdoor use but does not necessarily have the same high level of resistance to water as marine plywood. Marine grade just means it has no voids. 【solved】click here to get an answer to your question : Nor does it mean water can sit on top of for prolonged periods of time. Its unique composition and manufacturing process set it apart, making it. Yep, there's a reason they sell marine varnish to put on your marine plywood. Inner veneers are also of higher. Did you know marine grade plywood can last two to three times longer than regular plywood when sealed? It is mostly used in making luxury yachts, patios. Marine grade plywood is typically made from durable hardwood species, such as oak, mahogany, or douglas fir. There are several reasons why builders would choose to use marine grade plywood for marine construction projects: Nor does it mean water can sit on top of for prolonged periods of time. One of the most prominent applications of marine grade plywood is in boat building. 【solved】click here to get an answer to your question : When would a builder most likely use marinegrade plywood? Yep, there's a reason they sell marine varnish to put on your marine plywood. Marine grade just means it has no voids. To begin we must explain how the grades are intended to inform the builder of the uses and limits of the plywood and compare that to suggestions from our technician and other. 【solved】click here to get an answer to your question : There are several reasons why builders would choose to use marine grade plywood for marine construction projects: In. To begin we must explain how the grades are intended to inform the builder of the uses and limits of the plywood and compare that to suggestions from our technician and other. Marine grade just means it has no voids. Yep, there's a reason they sell marine varnish to put on your marine plywood. Marine grade plywood is typically made. When would a builder most likely use marinegrade plywood? It is mostly used in making luxury yachts, patios. Its unique composition and manufacturing process set it apart, making it. This makes marine ply grade key for projects in wet areas, like boat. Yep, there's a reason they sell marine varnish to put on your marine plywood. When would a builder most likely use marinegrade plywood? Marine grade plywood is typically made from durable hardwood species, such as oak, mahogany, or douglas fir. There are several reasons why builders would choose to use marine grade plywood for marine construction projects: Exterior plywood, on the other hand, is plywood designed for outdoor use but does not necessarily have. 【solved】click here to get an answer to your question : Marine grade just means it has no voids. Did you know marine grade plywood can last two to three times longer than regular plywood when sealed? Exterior plywood, on the other hand, is plywood designed for outdoor use but does not necessarily have the same high level of resistance to. When would a builder most likely use marinegrade plywood? Did you know marine grade plywood can last two to three times longer than regular plywood when sealed? There are several reasons why builders would choose to use marine grade plywood for marine construction projects: Inner veneers are also of higher. Marine grade plywood is a specialized material, a step above. Nor does it mean water can sit on top of for prolonged periods of time. Marine grade plywood is a specialized material, a step above the regular varieties you might be more familiar with. In today’s modern world, the importance of marine grade plywood is still the same and can be used for building furniture of your patio and outdoor. Marine grade plywood is a specialized material, a step above the regular varieties you might be more familiar with. There are several reasons why builders would choose to use marine grade plywood for marine construction projects: In this guide from building materials nationwide, we’ll explain the key information on marine. Marine grade just means it has no voids. Its resistance. When would a builder most likely use marinegrade plywood? 【solved】click here to get an answer to your question : To begin we must explain how the grades are intended to inform the builder of the uses and limits of the plywood and compare that to suggestions from our technician and other. Inner veneers are also of higher. Did you know. In today’s modern world, the importance of marine grade plywood is still the same and can be used for building furniture of your patio and outdoor projects. One of the most prominent applications of marine grade plywood is in boat building. 【solved】click here to get an answer to your question : Nor does it mean water can sit on top. Marine grade just means it has no voids. One of the most prominent applications of marine grade plywood is in boat building. Did you know marine grade plywood can last two to three times longer than regular plywood when sealed? 【solved】click here to get an answer to your question : In today’s modern world, the importance of marine grade plywood is still the same and can be used for building furniture of your patio and outdoor projects. It is mostly used in making luxury yachts, patios. Marine grade plywood is a specialized material, a step above the regular varieties you might be more familiar with. This makes marine ply grade key for projects in wet areas, like boat. Marine grade plywood is typically made from durable hardwood species, such as oak, mahogany, or douglas fir. When would a builder most likely use marinegrade plywood? There are several reasons why builders would choose to use marine grade plywood for marine construction projects: Inner veneers are also of higher. To begin we must explain how the grades are intended to inform the builder of the uses and limits of the plywood and compare that to suggestions from our technician and other. Nor does it mean water can sit on top of for prolonged periods of time. In this guide from building materials nationwide, we’ll explain the key information on marine.Grades Of Marine Plywood Understanding The Different Types

Understanding Marine Plywood Grades A Comprehensive Guide

PONTOON PLYWOOD TEST RESULTS Marine Grade VS. Treated Marine Grade

Difference between regular plywood and marine plywood

What is Marine Plywood Made From?

What is Marine Grade Plywood? Precision Plywood

Bruynzeel Marine Plywood is the Perfect for Boat Builders

MDO vs Marine Plywood What is the Difference? BuilderBaron

Marine Plywood Advantages And Disadvantages Timber Blogger

4 Reasons to Use Marine Plywood Home Expressions

Exterior Plywood, On The Other Hand, Is Plywood Designed For Outdoor Use But Does Not Necessarily Have The Same High Level Of Resistance To Water As Marine Plywood.

Yep, There's A Reason They Sell Marine Varnish To Put On Your Marine Plywood.

Its Resistance To Water Damage Makes It Ideal For Hulls, Decks, And Interiors, Providing.

Its Unique Composition And Manufacturing Process Set It Apart, Making It.

Related Post: