Building Prop Pedestals Of Plywood Sheets

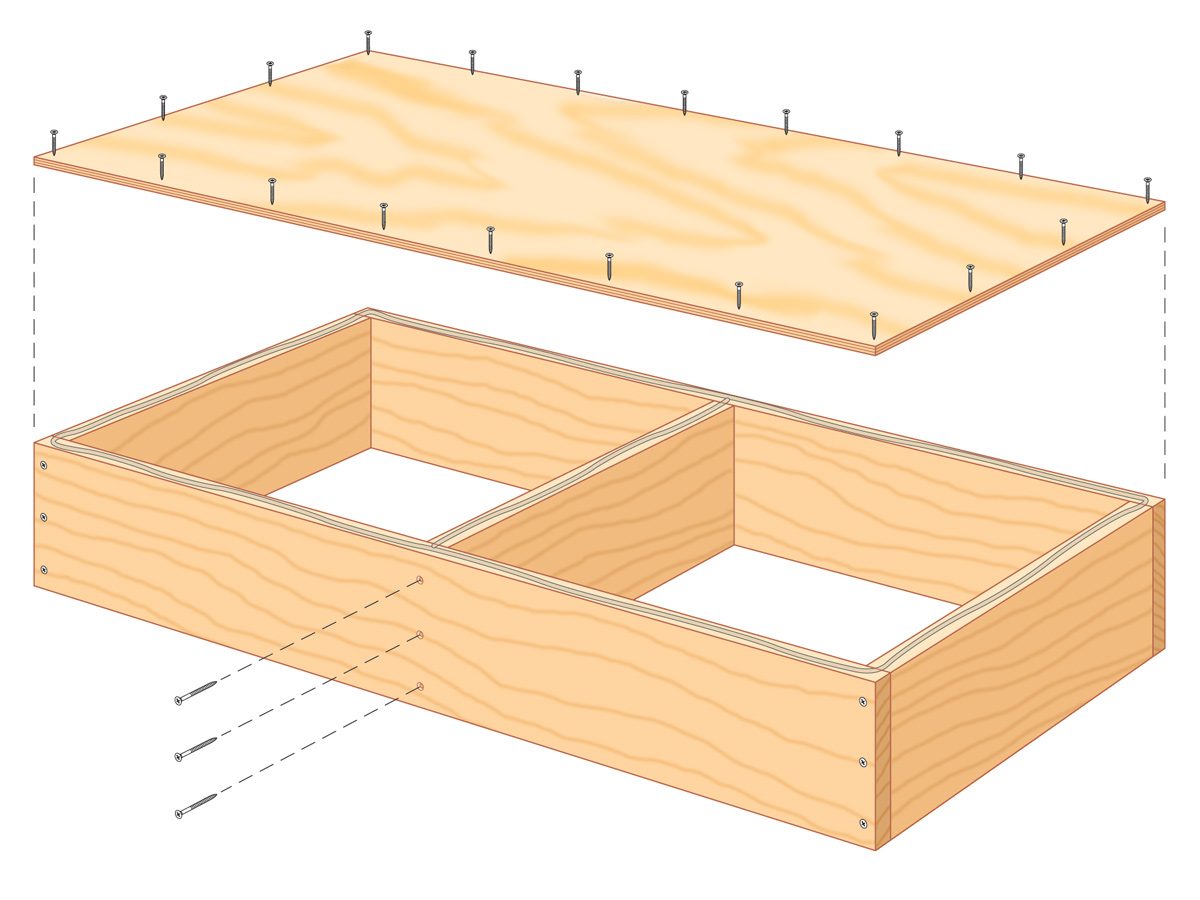

Building Prop Pedestals Of Plywood Sheets - Not so much to use them, but to have them as a keepsake, i would invest in 1/4 plywood as a minimum thickness. Use frame to trace “open” areas onto plywood. Here we've gone even more minimal: One foot high box pedestal: Drill the holes for the mount and attach capture nuts to the underside so i can bolt mount down, but not. See further down for a directory of plinth suppliers, and topics such. Today's plywood quality dictates that this pm38 boat would need to be made with true marine plywood, probably in the vicinity of $60.00 a sheet for the thickness specified in. & we didn't want to spend $400 for the factory pedestals, so i'm making my own. I typically start by making the panels oversized and trimming them to the correct size after they are dry and sanded smooth. Sandwich two 3/4 sealed, 12 x 12, plywood sheets together with pl. Here is a list of materials i have found to be the most cost effective and easiest to work with for building your marching band props. I started by drawing out a simple boat shape on a sheet of ply wood by measuring and marking the outside area first and then the inside area. These projects are perfect for beginners and experienced diyers alike. Another option is to use a 4’x8′ pylwood sheet with a wood veneer. Start with the shape, then cut a slot the width of the plywood, starting from the top down half way on one piece, the halfway up on the other piece. Today's plywood quality dictates that this pm38 boat would need to be made with true marine plywood, probably in the vicinity of $60.00 a sheet for the thickness specified in. Try this diy idea for creating modern plywood shelving organization for props, trinkets, books, etc. Building our own washer, dryer pedestals. This way they interlock and. I built a lumber storage rack that allows storing full size sheets on one side and standing up smaller boards on the other. You can buy a sheet of 4x8 one quarter inch plywood for under $30. & we didn't want to spend $400 for the factory pedestals, so i'm making my own. It has 6 casters so it easily rolls away from the wall when i need. I built a lumber storage rack that allows storing full size sheets on one side. I started by drawing out a simple boat shape on a sheet of ply wood by measuring and marking the outside area first and then the inside area. One foot high box pedestal: Here is a list of materials i have found to be the most cost effective and easiest to work with for building your marching band props. Cutting. Use frame to trace “open” areas onto plywood. One foot high box pedestal: Cover the frame on both sides using 1⁄2” x 4’ x 8’ plywood. See further down for a directory of plinth suppliers, and topics such. This way they interlock and. I typically start by making the panels oversized and trimming them to the correct size after they are dry and sanded smooth. I started by drawing out a simple boat shape on a sheet of ply wood by measuring and marking the outside area first and then the inside area. Use frame to trace “open” areas onto plywood. A place. A place to discuss aspects of tardis prop building. If you have a 4x8 sheet of plywood that you will be cutting down to 4x6, then you can use that 4x2 foot piece to make those barricades that you were talking about. Cover the frame on both sides using 1⁄2” x 4’ x 8’ plywood. These projects are perfect for. Statue plinths should be stable, should complement the sculpture, complement the surroundings, and should be affordable. You can buy a sheet of 4x8 one quarter inch plywood for under $30. This project goes into detail on designing an entertainment center to accommodate cords and heat, cutting plywood to size with a circular saw, cutting joints with a router, edging. It. Today's plywood quality dictates that this pm38 boat would need to be made with true marine plywood, probably in the vicinity of $60.00 a sheet for the thickness specified in. See further down for a directory of plinth suppliers, and topics such. Drill the holes for the mount and attach capture nuts to the underside so i can bolt mount. I built a lumber storage rack that allows storing full size sheets on one side and standing up smaller boards on the other. This project goes into detail on designing an entertainment center to accommodate cords and heat, cutting plywood to size with a circular saw, cutting joints with a router, edging. Cover the frame on both sides using 1⁄2”. Use frame to trace “open” areas onto plywood. I built a lumber storage rack that allows storing full size sheets on one side and standing up smaller boards on the other. Once plywood is cut, secure plywood to each side of frame using 8d nails. It has 6 casters so it easily rolls away from the wall when i need.. Once plywood is cut, secure plywood to each side of frame using 8d nails. These projects are perfect for beginners and experienced diyers alike. It has 6 casters so it easily rolls away from the wall when i need. Sandwich two 3/4 sealed, 12 x 12, plywood sheets together with pl. Cutting out parts, & starting assembly. These projects are perfect for beginners and experienced diyers alike. Cutting out parts, & starting assembly. In this blog post, we’ll explore ten simple and practical plywood furniture plans you can build yourself. Once plywood is cut, secure plywood to each side of frame using 8d nails. Cover the frame on both sides using 1⁄2” x 4’ x 8’ plywood. You can buy a sheet of 4x8 one quarter inch plywood for under $30. Then, i took both sheets of plywood and. Another option is to use a 4’x8′ pylwood sheet with a wood veneer. This project goes into detail on designing an entertainment center to accommodate cords and heat, cutting plywood to size with a circular saw, cutting joints with a router, edging. I built a lumber storage rack that allows storing full size sheets on one side and standing up smaller boards on the other. Plywood sheet sizes in the uk. Use frame to trace “open” areas onto plywood. Building our own washer, dryer pedestals. A place to discuss aspects of tardis prop building. Start with the shape, then cut a slot the width of the plywood, starting from the top down half way on one piece, the halfway up on the other piece. Try this diy idea for creating modern plywood shelving organization for props, trinkets, books, etc.How to Build a Pedestal 8 Steps (with Pictures) Instructables

Ana White Faux Stone Pedestal Made from Plywood scraps DIY Projects

Custom Plywood Pedestal in Natural Plywood Made in Ply

Plywood Pedestal Small Surface 6x6 Etsy

Plinth Pedestal Plant Stand Stand Plywood Wood Etsy

How to Build a Plywood Retail Display YouTube

DIY Washer Pedestal The Family Handyman

PD069 Andy Tall Natural Wood Pedestal Prop Rental ACME Brooklyn

Bespoke plywood pedestals

PD030S Meyer 25" Low and 32" Tall Pedestal Pair Prop Rental ACME

See Further Down For A Directory Of Plinth Suppliers, And Topics Such.

Here We've Gone Even More Minimal:

Statue Plinths Should Be Stable, Should Complement The Sculpture, Complement The Surroundings, And Should Be Affordable.

I Typically Start By Making The Panels Oversized And Trimming Them To The Correct Size After They Are Dry And Sanded Smooth.

Related Post: