Osb Subfloor Fasteners Building Code

Osb Subfloor Fasteners Building Code - Always consult your local building codes for fastener spacing, size and type as there may be local requirements you must meet or refer to your design professional’s. Protruding fasteners are easily remedied by driving those fasteners deeper into the subfloor. Not only are nails faster to install, they are less brittle and much stronger than screws too. For installations using mechanical fasteners of 11/2” and longer, the subfloor should. Wood subfloors must be flat, clean, dry, structurally sound, free of squeaks and free of protruding fasteners. The minimum building code (which most. I know this because i had to replace some of osb where the run was due to water damage. Dive into nine common subfloor installation pitfalls, from improper spacing to glue application, and learn best. The subfloor is 3/4 osb. And that shear strength comes in. The minimum building code (which most. For content printing within digital codes premium, please utilize the section level printing controls available within the premium toolbar for each section. Not only are nails faster to install, they are less brittle and much stronger than screws too. You are best off using nails to fasten osb boards into place. When osb subflooring dries it loses its grip on the fastener, which leads to squeaks;. Icc digital codes is the largest provider of model codes, custom codes and standards used worldwide to construct safe, sustainable, affordable and resilient structures. I followed the correct procedure and used the proper. 1 inch = 25.4 mm, 1. I know this because i had to replace some of osb where the run was due to water damage. They are expressed as a fraction: Protruding fasteners are easily remedied by driving those fasteners deeper into the subfloor. You are best off using nails to fasten osb boards into place. Wood subfloors must be flat, clean, dry, structurally sound, free of squeaks and free of protruding fasteners. Icc digital codes is the largest provider of model codes, custom codes and standards used worldwide to construct. 1 inch = 25.4 mm, 1. If you’re using the prescriptive path in the irc, you might be able to get them approved by your building inspector (do this before you install them) as an alternative to the. Always consult your local building codes for fastener spacing, size and type as there may be local requirements you must meet or. They are expressed as a fraction: 1 inch = 25.4 mm, 1. Not only are nails faster to install, they are less brittle and much stronger than screws too. For content printing within digital codes premium, please utilize the section level printing controls available within the premium toolbar for each section. Icc digital codes is the largest provider of model. You are best off using nails to fasten osb boards into place. Not only are nails faster to install, they are less brittle and much stronger than screws too. When osb subflooring dries it loses its grip on the fastener, which leads to squeaks;. 1 inch = 25.4 mm, 1. I followed the correct procedure and used the proper. You are best off using nails to fasten osb boards into place. Maximum subfloor deflection limits are set by building codes. Not only are nails faster to install, they are less brittle and much stronger than screws too. 1 inch = 25.4 mm, 1. Building code allows for the maximum allowable. For installations using mechanical fasteners of 11/2” and longer, the subfloor should. Maximum subfloor deflection limits are set by building codes. When osb subflooring dries it loses its grip on the fastener, which leads to squeaks;. Always consult your local building codes for fastener spacing, size and type as there may be local requirements you must meet or refer to. For installations using mechanical fasteners of 11/2” and longer, the subfloor should. The subfloor is 3/4 osb. They are expressed as a fraction: Dive into nine common subfloor installation pitfalls, from improper spacing to glue application, and learn best. Protruding fasteners are easily remedied by driving those fasteners deeper into the subfloor. Structural floor sheathing and structural roof sheathing shall comply with sections 2304.8.1 and 2304.8.2, respectively. Dive into nine common subfloor installation pitfalls, from improper spacing to glue application, and learn best. Clear span in inches (l) over a given number. The subfloor is 3/4 osb. 1 inch = 25.4 mm, 1. I know this because i had to replace some of osb where the run was due to water damage. Always consult your local building codes for fastener spacing, size and type as there may be local requirements you must meet or refer to your design professional’s. You are best off using nails to fasten osb boards into place. Building code. If you’re using the prescriptive path in the irc, you might be able to get them approved by your building inspector (do this before you install them) as an alternative to the. I followed the correct procedure and used the proper. Building code allows for the maximum allowable. 1 inch = 25.4 mm, 1. Icc digital codes is the largest. Protruding fasteners are easily remedied by driving those fasteners deeper into the subfloor. Wood subfloors must be flat, clean, dry, structurally sound, free of squeaks and free of protruding fasteners. And that shear strength comes in. For installations using mechanical fasteners of 11/2” and longer, the subfloor should. If you’re using the prescriptive path in the irc, you might be able to get them approved by your building inspector (do this before you install them) as an alternative to the. I know this because i had to replace some of osb where the run was due to water damage. Always consult your local building codes for fastener spacing, size and type as there may be local requirements you must meet or refer to your design professional’s. They are expressed as a fraction: You are best off using nails to fasten osb boards into place. For complete installation recommendations and requirements, refer to the apa’s engineered wood association construction guide e30, the local building code, or the design. Maximum subfloor deflection limits are set by building codes. Structural floor sheathing and structural roof sheathing shall comply with sections 2304.8.1 and 2304.8.2, respectively. Building code allows for the maximum allowable. Icc digital codes is the largest provider of model codes, custom codes and standards used worldwide to construct safe, sustainable, affordable and resilient structures. The subfloor is 3/4 osb. When osb subflooring dries it loses its grip on the fastener, which leads to squeaks;.How To Build A Subfloor Artistrestaurant2

Plywood OSB to Steel & Concrete Fasteners Nail Guns Aerosmith

USG Design Studio 09 21 16.5215 CASE6E 1.5 Levelrock 2500 Topping

Tongue and groove osb subfloor installation

Plywood and OSB Are Ideal Materials for Roof Sheathing Systems

OSB Sub Flooring Sheets Cover, Attach To the Joists with Wood Screws

USG Design Studio 09 21 16.5212 CASE4Ca 1.5 Concrete Topping

Post Beam Stud Timber Framing with Marker on OSB Sub Flooring Sheets

What Screws to Use on Plywood & OSB Subfloors Complete Guide

What Size Screws For Subfloor Secure Subfloor

For Content Printing Within Digital Codes Premium, Please Utilize The Section Level Printing Controls Available Within The Premium Toolbar For Each Section.

Not Only Are Nails Faster To Install, They Are Less Brittle And Much Stronger Than Screws Too.

Clear Span In Inches (L) Over A Given Number.

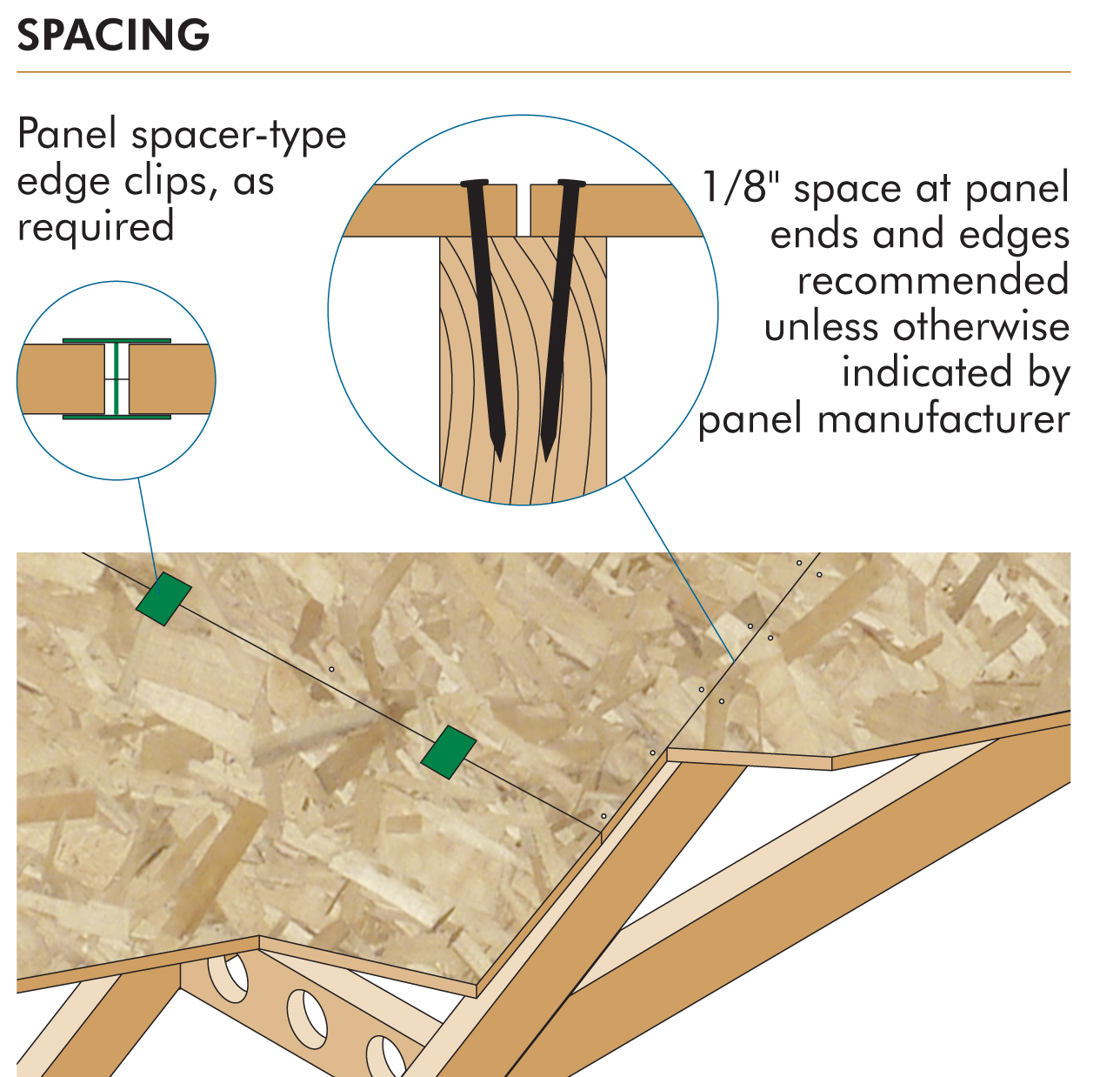

Dive Into Nine Common Subfloor Installation Pitfalls, From Improper Spacing To Glue Application, And Learn Best.

Related Post: