Building Up Chrome Molybdenum Coating

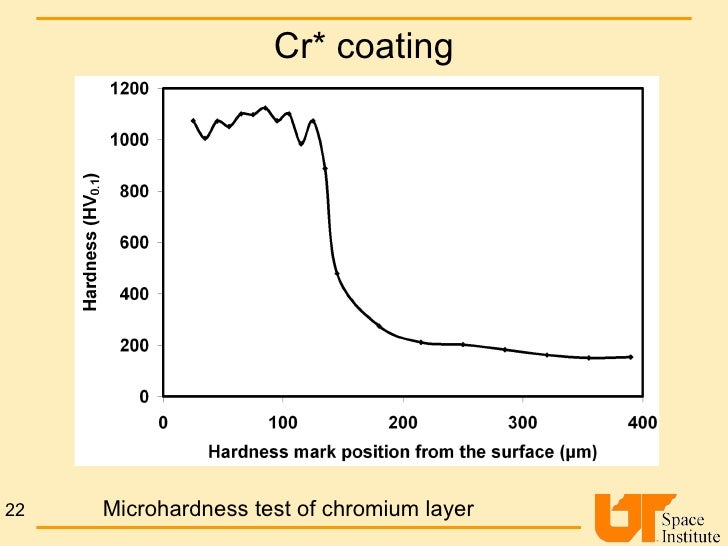

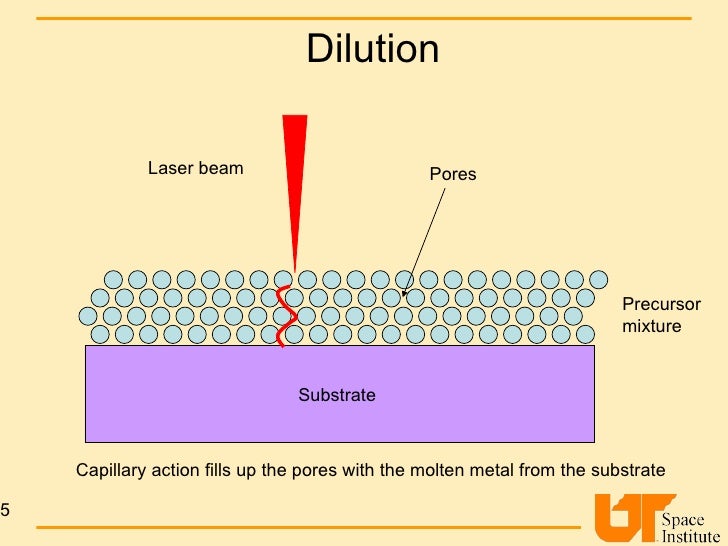

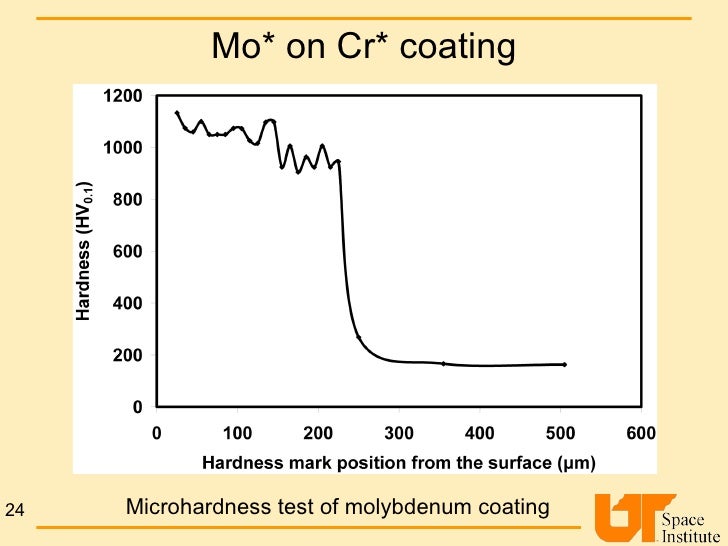

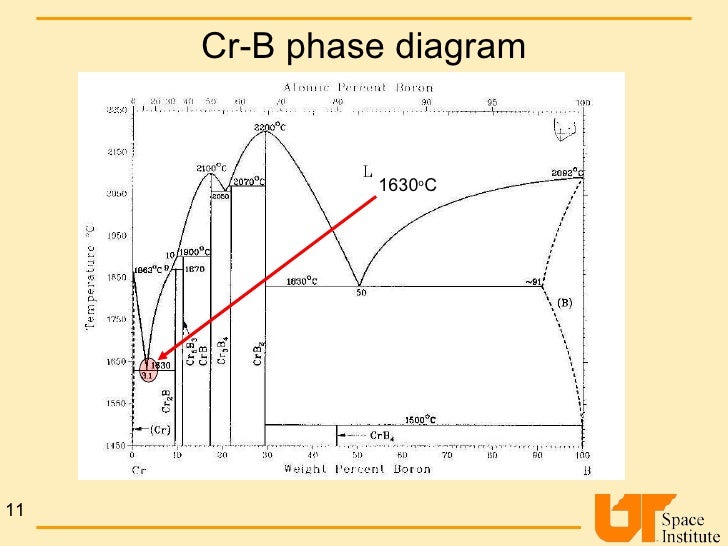

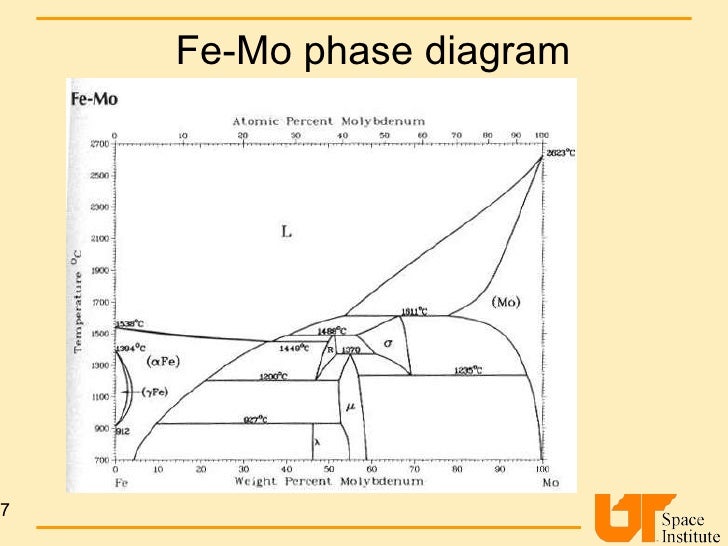

Building Up Chrome Molybdenum Coating - Last week, the forum offered some good advice on the purchase of a 5.56 lower for a provisional or future build. Hvof coatings are typically about 0.003 to 0.005 thick on original parts, and 0.015 thick on rebuilt parts because manufacturers are building up the worn area. When damage occurs, employing the right repair techniques is essential to restore the integrity of the chromium coating. The bullet contact surface in the barrel is only so big. Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to give it a specific hardness, wear resistance, or corrosion resistance. Bushmaster and colt, and a few others use the slightly tougher 4150. But when your round goes off, moly comes off the contact. The smith & wesson ar15 sport i previously purchased has a. This is difficult with older system designs but entirely possible using today’s innovations; The chrome is not a coating, but is part of the alloy. But when your round goes off, moly comes off the contact. The smith & wesson ar15 sport i previously purchased has a. Bushmaster and colt, and a few others use the slightly tougher 4150. There is no way possible to coat a bore with moly bullets. Most chromemoly gun barrels are made from 4140. The bullet contact surface in the barrel is only so big. This is difficult with older system designs but entirely possible using today’s innovations; When damage occurs, employing the right repair techniques is essential to restore the integrity of the chromium coating. Last week, the forum offered some good advice on the purchase of a 5.56 lower for a provisional or future build. Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to give it a specific hardness, wear resistance, or corrosion resistance. Most chromemoly gun barrels are made from 4140. This is difficult with older system designs but entirely possible using today’s innovations; The chrome is not a coating, but is part of the alloy. Last week, the forum offered some good advice on the purchase of a 5.56 lower for a provisional or future build. When damage occurs, employing the right. A heavy dense deposit of chrome and chrome build up is used to provide wear resistance on such parts as pistons,. What you did to prime/paint/finish your cabin frame? There is no way possible to coat a bore with moly bullets. Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to. There is no way possible to coat a bore with moly bullets. Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to give it a specific hardness, wear resistance, or corrosion resistance. A heavy dense deposit of chrome and chrome build up is used to provide wear resistance on such parts. Bushmaster and colt, and a few others use the slightly tougher 4150. Last week, the forum offered some good advice on the purchase of a 5.56 lower for a provisional or future build. There is no way possible to coat a bore with moly bullets. In the present study, the chromium intermediate layer and the molybdenum final coating chemistries are. Hvof coatings are typically about 0.003 to 0.005 thick on original parts, and 0.015 thick on rebuilt parts because manufacturers are building up the worn area. Last week, the forum offered some good advice on the purchase of a 5.56 lower for a provisional or future build. This is difficult with older system designs but entirely possible using today’s innovations;. A heavy dense deposit of chrome and chrome build up is used to provide wear resistance on such parts as pistons,. This is difficult with older system designs but entirely possible using today’s innovations; When damage occurs, employing the right repair techniques is essential to restore the integrity of the chromium coating. Most chromemoly gun barrels are made from 4140.. The bullet contact surface in the barrel is only so big. What you did to prime/paint/finish your cabin frame? The smith & wesson ar15 sport i previously purchased has a. A heavy dense deposit of chrome and chrome build up is used to provide wear resistance on such parts as pistons,. Hvof coatings are typically about 0.003 to 0.005 thick. But when your round goes off, moly comes off the contact. The chrome is not a coating, but is part of the alloy. In the present study, the chromium intermediate layer and the molybdenum final coating chemistries are based on their eutectic systems with boron (i.e. Hardfacing or surface coating is a process of spraying or welding metallic powders onto. What you did to prime/paint/finish your cabin frame? When damage occurs, employing the right repair techniques is essential to restore the integrity of the chromium coating. Most chromemoly gun barrels are made from 4140. Bushmaster and colt, and a few others use the slightly tougher 4150. The smith & wesson ar15 sport i previously purchased has a. Most chromemoly gun barrels are made from 4140. This is difficult with older system designs but entirely possible using today’s innovations; In the present study, the chromium intermediate layer and the molybdenum final coating chemistries are based on their eutectic systems with boron (i.e. When damage occurs, employing the right repair techniques is essential to restore the integrity of the. When damage occurs, employing the right repair techniques is essential to restore the integrity of the chromium coating. There is no way possible to coat a bore with moly bullets. But when your round goes off, moly comes off the contact. Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to give it a specific hardness, wear resistance, or corrosion resistance. A heavy dense deposit of chrome and chrome build up is used to provide wear resistance on such parts as pistons,. In the present study, the chromium intermediate layer and the molybdenum final coating chemistries are based on their eutectic systems with boron (i.e. Bushmaster and colt, and a few others use the slightly tougher 4150. Hvof coatings are typically about 0.003 to 0.005 thick on original parts, and 0.015 thick on rebuilt parts because manufacturers are building up the worn area. What you did to prime/paint/finish your cabin frame? The chrome is not a coating, but is part of the alloy. The bullet contact surface in the barrel is only so big. The smith & wesson ar15 sport i previously purchased has a.MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

Molybdenum Disulfide "Moly" Coatings Custom Coatings International

MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

MolybdenumonChromium Dual Coating on Steel

Last Week, The Forum Offered Some Good Advice On The Purchase Of A 5.56 Lower For A Provisional Or Future Build.

This Is Difficult With Older System Designs But Entirely Possible Using Today’s Innovations;

Most Chromemoly Gun Barrels Are Made From 4140.

Related Post: